Installation of sewer wells

The sewage system consists not only of the pipeline, but also of wells. The principle of their installation is almost the same, but they all can perform different functions. For the construction of the well, various materials are used: reinforced concrete rings, brick, cinder block, metal and plastic containers, and automobile tires. In general, each owner uses the material that is at hand. But for the system to work well, it is necessary to properly install the sewer manholes, observing all building codes.

Variety and rules for the installation of wells

The number and type of wells installed depends on the type of sewerage, its length, drops, turns.

Tip! In the sewer, used only under the drain from the bathroom and sinks, it is enough to install a viewing and filtering well. If there is a drop or turn on the pipeline, then a drop well or a rotary well is installed in this place, respectively. Then you can not install the manhole, but combine it with one of them.

In the sewage system, where the drain from the toilet and the bathroom will be carried out by one pipeline, the first is installed well-sump. In it the solid sediment will settle to the bottom, and the water through the overflow will fall into the filter well. From the filtering well, purified water through the overflow flows into the third well - the drainage one. From the third well clean water will be discharged to a specific location or pumped out. The installation of these three wells is mandatory, plus a turning or viewing well may be added to them.

Well location

- Lookouts. The first well is installed at the exit of the sewage from the building, no closer than 3 m from the foundation, but not further than 12 m. In the long-haul system, the wells are installed every 15 m.

- Swivel. Such wells are similar to manholes, only they are installed not at a certain distance, but at all turns of the pipeline. And if the manhole is installed next to the turntable, then it can be removed.

- Delta. Sewerage passing through difficult terrain, in some places may have drops. A drop well is installed at such a junction point. In very long pipelines, the velocity of the drained water increases and may cause a breakthrough in the system. Here the drop point will perform the rescue function of quenching the flow rate of water.

All considered sewer manholes are different device bottom. In the drainage wells, the bottom is not concreted, but filled with filtering material, through which clean water flows. All other wells have a horizontal concrete bottom, only for sedimentation tanks the bottom is concreted in the form of a cone, or sloped. The installation of the casing of wells is almost the same, although there are some nuances due to the difference in materials.

Installation of sumps

According to the design, sedimentation tanks are divided into vertical and horizontal. Their installation differs significantly.

Horizontal design

Reinforced concrete is mainly used to build a horizontal sump. The shape of the well resembles a rectangle with partitions for cameras (basically there are two of them). Chambers collect solid accumulations in the form of sediment at the bottom. The upper edge of the installed sedimentation tank is not more than 60 cm in the ground, and the water level in the chamber should not reach a surface of 40 cm. Sedimentary bottom is poured with concrete under a slope.

Vertical construction

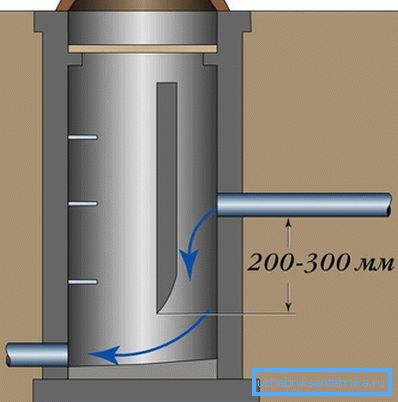

Installation of the vertical sump is made of reinforced concrete rings, and the bottom is concreted in the form of a cone. The impurities that fall into such a structure leave solid particles at the bottom, and the liquid, changing the direction of movement, enters the drain pipe. The height of the sides of the overflow channel float regulates the water level.

The size of the sedimentary bottom is built at the rate of 0.8 l sediment per person per day. In the sedimentary part, the sediment of the process of vital activity of all living people in a room for two days should fit. In the future, it is drained through a 200 mm pipe installed at the bottom of the sump.

Tip! Installation of reinforced concrete rings or panels is carried out in the excavated excavation pit using a mobile crane. All joints are sealed with cement mortar, and the walls are covered with a waterproofing layer. Top cover with a concrete slab with a hatch.

Installation of a drainage well

Drainage wells are installed in a similar way to mount the rings. They can be replaced by brick masonry, cinder block. The only difference is that it is not installed on the concrete bottom, but on the filter pad. It consists of a layer of sand, a mixture of sand and gravel, and the third layer is large crushed stone. The thickness of each layer is from 15 to 25 cm.

Installation of other wells

Inspection, differential and rotary wells are installed both from concrete rings and brick, cinder block, barrels and other improvised materials. The horizontal bottom is filled with concrete 15 cm thick, and all walls are covered with waterproofing.

After reading the article, you know the types of wells, and where they should be installed. And the main work for the installation of all types of wells is almost the same: digging out a pit, concreting the bottom or pouring in a filter pad, building walls, covering them with waterproofing, covering them with a plate with a hatch, sprinkling them with earth. Most of the work can be done by hand, and for installation of concrete rings or panels will have to use the services of a crane. For a large amount of earthworks, it is better to use an excavator.

Video

Watch a small video report on the installation of a sewer well: