Methods of installation of water wells

Water wells according to SNiP are underground structures, the purpose of which is to install water supply equipment in them. These can be valves, valves, metering devices, shut-off valves, etc. These designs can have a rectangular or rounded shape.

General provisions

Requirements for the installation of external parts of engineering communications are contained in SNiP No. 2.04.0 / 84.

In general, the detailing of a water well looks like this.

- Its height from the level of drainage to the cover should be at least 150 cm.

- For networks with a cross section of up to 400 mm, the minimum gap from the wall of the structure to the pipe should be 30 cm. For sections of 500/600 mm - this is 50 cm, and with a system diameter greater than 600 mm - 70 cm.

- Pipe flanges with a cross-section of up to 40 cm should be located, at a minimum, 0.3 m from the walls. If the diameter is more than 40 cm, the gap increases to 0.5 m.

Note! This instruction improves installation convenience. If the size of the flange is large, then thick bolts are used for fixing, they often have to be tightened with a long lever.

- The gap from the end of the socket, facing the wall, for its cross-section up to 30 cm should be from 40 cm, for a diameter greater than this value –0.5 m.

- The top of the retractable stems of the plugs must be separated from all surfaces of 30 cm. The steering wheel with a fixed type of rod requires 50 cm of free space.

From the bottom of the pipe to the level of bedding should be:

- with their cross-section up to 40 cm - 25 centimeters;

- with a diameter of 50 / 60-30;

- with a cross section greater than 60-35.

Note! To penetrate the well, it is desirable to equip its wall with your own steel or cast iron brackets. If you fail to do this, you can use a ladder or a ladder.

Manhole covers for water and sewer wells do not have to be insulated. Insulated elements are used if there is a technical justification. For example, in the area severe winters.

Reinforced concrete structures

The most common prefabricated factory wells of reinforced concrete.

What makes up such a well

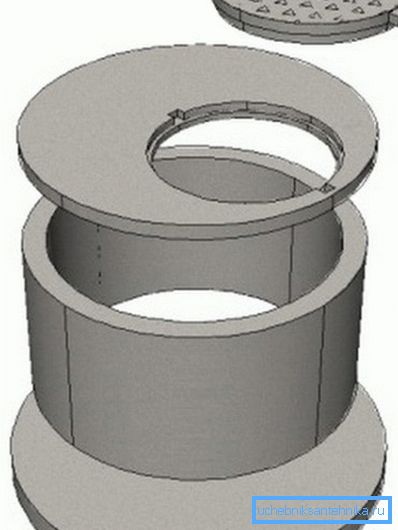

The device of a water well from concrete rings is as follows:

- road plate;

- ring is complementary;

- neck;

- floor slab;

- wall ring;

- hatch with cover;

- bottom plate.

The dimensions of the rings of water wells are given in the table.

| Product marking | Dimensions in mm | Weight in kg | Cost of | ||

| Height | Wall thickness | Int. diameter | |||

| COP / 7/1 | 100 | 80 | 700 | 46 | 340 |

| COP / 7 / 1.5 | 150 | 80 | 700 | 68 | 350 |

| COP / 7/3 | 350 | 80 | 700 | 140 | 590 |

| KS-7-5 | 500 | 80 | 700 | 230 | 800 |

| COP / 7/6 | 600 | 100 | 700 | 250 | 825 |

| COP / 7/9 | 900 | 80 | 700 | 410 | 1230 |

| COP / 7/10 | 1000 | 80 | 700 | 457 | 1280 |

| COP / 10/5 | 500 | 80 | 1000 | 320 | 1105 |

| COP / 10/6 | 600 | 80 | 1000 | 340 | 1130 |

| COP / 10/9 | 900 | 80 | 1000 | 640 | 1530 |

| COP / 12/10 | 1000 | 80 | 1200 | 1050 | 2115 |

| COP / 15/6 | 600 | 90 | 1500 | 900 | 2060 |

| COP / 15/9 | 900 | 90 | 1500 | 1350 | 2670 |

| COP / 20/6 | 600 | 100 | 2000 | 1550 | 3345 |

| COP / 20/9 | 900 | 100 | 2000 | 2300 | 4015 |

| COP / 25/9 | 900 | 120 | 2500 | 2200 | 16,100 |

| KO / 6 | 70 | 120 | 580 | 60 | 390 |

Mounting construction

Plumbing reinforced concrete wells are most often mounted for apartment buildings. For their own homes they are also used. However, in most cases, private owners fill in monolithic square or rectangular-shaped structures (they require simpler formwork than for round counterparts). Construction organizations use more sophisticated methods using ready-made factory rings.

Further briefly about how the self-installation of water wells from reinforced concrete.

- It should be noted that the formwork device will be complicated as it must have openings for the network trays and the entrance.

- First you need to dig a pit. Its walls should be 20 cm wider than the size of the future well.

- Next to the bottom of the pit should be poured 20 cm of gravel or sand. This layer will form the basis of the walls and serve as drainage.

- The walls of the pit must be covered with rolled waterproofing - plastic wrap, waterproofing, roofing felt. Such a flooring also does not allow water from concrete to be absorbed into the soil, thereby reducing the strength of the structure.

- Then the reinforcing frame is mounted. It can be made of corrugated rods, tied with annealed wire or factory mesh.

- Then the formwork gets off. The material for it can serve as moisture-resistant plywood, boards, OSB, smooth slate, etc.

- Factory concrete M-200 or independently mixed mixture is poured into the finished box in layers of 30 cm each. The proportions of the solution: 1 share of cement, 3 shares of quartz sand and 3 shares of gravel. Each of the poured layers is rammed with a splicing.

- When the concrete is completely dry, a factory plate is placed on top, which has a cap and hatch of a water well.

Brick counterparts

The device of water wells from a brick - more labor-intensive process. Dimensions of the pit for them should be larger than for concrete counterparts. The fact is that the brick needs external waterproofing, which is equipped with several layers of heated bitumen.

Note! In this case, it is necessary to carry out laying only from yellow or red ceramic bricks. Silicate is made on the basis of lime and is rapidly destroyed in the environment of moisture.

Put the material in half a brick. Its horizontal rows are tied at least 25% of the length of the elements. As a binder, it uses a cement-sand mixture in the ratio of 1: 3. The thickness of the masonry joints is 1 / 1.5 cm.

Finished plastic structures

- Plastic plant facilities make it possible to save a lot of time.

- The design of a water well of this type consists of a thick corrugated pipe made of PE or PP. The structure has branches for trays and sealing rings.

- To increase the ring stiffness of the structure, it is made with double-walled walls.

- The price of plastic wells is quite high - a two-meter product with a section of 0.7 m costs 15/17 thousand rubles.

Installation of facilities

- A pit is digging, a little larger than the well itself. 15/20 cm will be enough.

- Sand cushion falls.

- Next, the structure is lowered into the pit.

- If the structure has a submersible chamber, it is filled with concrete. Due to this, the well will not float in wet soil.

- Communications and equipment are installed in the building.

- Backfilling is performed.

Conclusion

The wells for the water supply network have an important function. They house equipment that regulates and controls the operation of the system.

The video in this article will help you understand its topic.