Plastic sewer well: overview

Products from polymers have long entered our lives. They are widely used in everyday life, industry, when laying various communications. So, in many personal plots you can find a plastic sewer well. This design is reliable, easy to install and operate, and is not so expensive.

Advantages of designs

More recently, concrete structures were used to create sewer manholes or they were made using brick masonry. Such structures are quite strong and durable, but plastic products have a number of indisputable advantages:

- they weigh little, which greatly facilitates transportation and installation;

- have low thermal conductivity, which additionally protects communications from freezing;

- resistant to the harmful effects of aggressive environments and moisture;

- plasticity - does not collapse when exposed to frozen water and from the pressure of the soil;

- can be equipped with built-in additional elements (for example, ladders);

- there is an opportunity to regulate on height both in the course of installation, and during operation;

- have all the devices that facilitate connections to them sewer pipes and additional devices.

In addition, products made of polymers have sufficient strength, so their service life is no different from concrete or brick structures. In addition, wells can have a variety of forms. Products can be purchased in a ready-made form or order their production according to individual drawings.

Design features and manufacturing standards

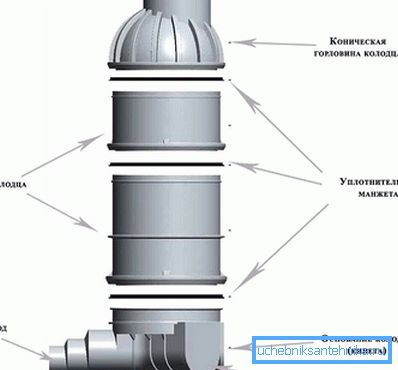

The plastic wells themselves are a tubular structure having the following main parts:

- the throat is the upper component, in which there are various devices for installing the hatch;

- the body of the well or mine pipe;

- tray part. This is where all the wiring and other devices for connecting pipes. The tray part is equipped with an airtight bottom.

At production various materials are used. It may be:

- polyvinyl chloride;

- polyethylene;

- polypropylene.

Each material has its own advantages. So, PVC products (polyvinyl chloride) are non-flammable and have a high resistance to chemical attack. Polyethylene structures have a high degree of tightness. In addition, such products can recover their shape after deformation from frozen water. Polypropylene wells have greater plasticity.

Tip! To maximize the benefits of each polymer, manufacturers offer a combination of products. Their elements can be made of different materials.

The body of the well itself can be in the form of a corrugated or smooth-walled pipe. The first option is considered more durable. The tray part is made with smooth and thicker walls. The neck can have a diameter of up to 1 meter, in the case of an unserviceable well, and more than 1 meter, if it is intended to serve communications.

At the top of the neck is covered with a plastic hatch. When buying a product, it is worth paying attention to its labeling; the withstand loads depend on it. So, there are products with the following characteristics available:

- A15 standard. Such hatches can withstand up to 1.5 tons, which is quite enough for installation on footpaths and the lawn part of the site;

- B125 standard, can withstand up to 12.5 tons of load. This allows you to install the hatch in parking lots and parking lots;

- standard S250. Used for installation on roads, capable of withstanding loads up to 25 tons;

- D400 standard is mainly used on motorways and withstands 40 tons.

Also, when buying products, pay attention to their purpose:

- Lookouts. They are installed in places of rotation of the communication line and on long straight sections. They are intended for system maintenance (cleaning and repair). In addition, such products (depending on the installed tray part) can also serve as a junction of several sewage branches.

- Absorption - used to discharge wastewater into the soil with pre-filtration. Such structures are made without a bottom, and gravel or crushed stone is used as a filtering element.

- Water intake - used to collect waste and their subsequent pumping. Have a large volume and tightness.

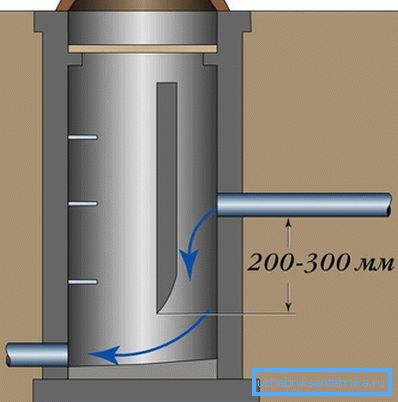

- Differential - used in places with a large difference between the levels of sewer.

Each of them has its own design features and dimensions.

Monolithic and prefabricated structures

Monolithic products are used in those places where a high compressive strength is required. They are made with built-in devices for connecting pipes, and with the calculation of the use of welding. These wells are well established as a drop.

Tip! Monolithic wells are cheaper collapsible. But they have some drawbacks. Such designs are more difficult to transport and install.

More expensive collapsible constructions consist of several parts, which are assembled directly at the installation site. This greatly facilitates all the work. But this feature creates the risk of loss of tightness.

Which one to choose is an individual decision. Some believe that fewer compounds increase the reliability of the design. For others, flexibility and the ability to easily adapt to the desired situation is important.

Video: Review

A photo