Pressure sewage device

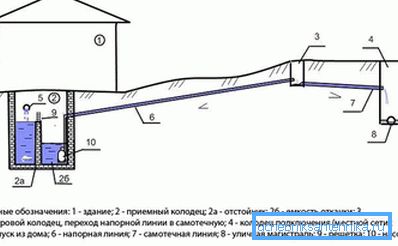

Pressure sewage is a network, the links of which are a sump, a pumping station and a pipeline transporting the drains by force. Laying of sewage ends connecting to the existing network. To make the device of the pressure head sewerage, certain knowledge and skills are necessary.

Specifications

Sewerage is gravity and pressure. Each system is arranged on the basis of external conditions. If external factors do not allow to build a self-flowing sewage system, then a pressure one is built, which has its advantages:

- Long service life. If we take into account cast iron, PE or PVC pipes, which are often used for pressure sewage, they have recently been produced of sufficiently high quality.

- The likelihood of blockages in pipelines is minimized. Modern pumps are equipped with cutting edges that crush tissue and other solid fractions found in domestic wastewater.

- Comparative thrift. This applies to the pressure sewage system, which has a large length and small diameter.

- Simple rules of operation.

- Relatively simple and quick installation. To install a ready KNS you do not need to carry out large earthworks. The same applies to the installation of pressure pipelines, which run almost parallel to the relief of the earth.

- Compact CND. Pumping station for pressure sewage does not take up much space, so it can be installed even in the basement of the house.

Pressure sewage is arranged in the following cases:

- A domestic sewage discharge pipe in a private house is located below the connection point, for example, an existing sewer network;

- the terrain along the line of laying pressure sewage has significant differences;

- apply a closed method of laying a pipeline across the road;

- soil type or other reasons exclude the possibility of a deep trench;

- pressure pipe of small diameter.

Design work

The design of pressure sewage can make any relevant organization specializing in construction. If you have the necessary knowledge, this work can be done independently.

Designing pressure sewers begins with a study of geological and geodetic survey data. Proceeding from them, a well is selected on the network of the existing sewage system and the route of laying the pipeline is drawn to it. During the design, the pipeline’s laying depth and its diameter will be determined, structures and fittings on the road will be marked, the pump will be selected, its type and capacity will be selected. To choose a pump, you need to make a hydraulic calculation and schedule a joint work of the pressure pipe and the unit. When choosing a pump, it is necessary to take into account the geometric height of the lift and the pressure loss along the length of the pressure sewage pipeline. When laying pipes, it is necessary to take into account the terrain and try not to overly deepen the pipeline. To do this, along the length of the route you need to change the slopes. The sump well should be the lowest in the system. If there is a possibility, it is desirable to install a well with equipment on the highway, in which the pressure sewage system will turn into gravity flow. If the relief allows, the gravity piping should be as long as possible, and the pressure pipeline should be shorter.

Tip! Often, several owners of neighboring buildings to save on the construction of sewage are satisfied with a common receiving well, to which they connect their internal systems and from which they build one pressure branch.

Special features

Pumping station is the main component of pressure sewage. The design of the KNS includes a rotor, which has cutting edges. Thanks to them, the solid fractions are crushed and do not interfere with the effluent to pass freely through a pipeline whose diameter can be up to 110 mm. All parts of the pump are made of high-strength metal, therefore the unit has a rather long service life. Instead of cast iron pipes, which were recently used in the installation of pressure sewage, polyethylene or polyvinyl chloride are increasingly used. With a diameter of pipes up to 90 mm, such products are supplied in coils, which is convenient for installation.

Pump stations can be divided into 2 types:

- Intra-house. Such KNS divert wastewater from one house. They include a pump with a grinder and a plastic housing. As a rule, such a structure is installed in the basement.

- Outdoor They are designed for pumping waste from several houses. They pump water from a tank into which sewage gets gravity from different buildings. Wastewater is delivered to the sewage treatment plant or to the existing sewage system.

If you need a tie-in to the pressure sewage system, you need to collect the necessary number of permits and certificates, draw up an agreement for the reception of drains and call a special construction crew.

Pump selection

The type of pump is selected depending on the composition of the wastewater. For drains of economic origin from the shower, sink and sink, an ordinary pump may be suitable. But since faecal impurities from the toilet bowl are also used, which can also get solid fragments, the pump must be selected with a grinder. Its presence reduces the diameter of the pressure pipe to 40 mm.

Since large volumes of liquid are drained from baths, fonts and pools, pumps for them must have high performance. In addition, their uninterrupted work should be ensured for a long time. Another factor that must be taken into account when choosing a pump type, it should be designed for water temperatures up to 70? C, coming from the drains of the dishwasher and washing machine.

When installing the pump, there are certain rules:

- the temperature of the plus sign should always be at the pump installation site;

- the site for the installation of the KNS must be cleaned and have access to the approach;

- a support bend with a special flange should be installed at the bottom of the structure;

- pressure pipe is supported on the knee;

- the pipe at the top of the well is attached with a bracket fixed to the wall of the structure;

- the pipeline must be installed according to the rules - without distortions and stresses. The diameter of the discharge pipe must be smaller than the intake;

- in order to exclude a reverse current, a check valve and a valve are provided on the pressure pipe;

- for lowering and raising the pump, a chain fixed on the unit and a guide structure are used;

- when the pump reaches the lower knee, a tight connection automatically occurs.

Prefabricated Well Device

When the device of the pressure head sewerage occurs, a prefabricated well is an important link in the construction. It must be installed near the house for receiving wastewater. The bottom and walls of the well must be ensured reliable waterproofing. Otherwise, there is a high probability that sewage will leak into the ground. Surface finishes are usually made with concrete, rubble or baked bricks. The thickness should eventually reach about 25 cm. The outer side of the walls can be insulated with a layer of bitumen, the inner side of the well is plastered, that is, the seams are rubbed over. Often used in the construction of concrete rings, which are stacked on a special plate.

In order for the pump to be operated longer, it is desirable to arrange a well from two sections. The first section will collect wastewater. In the second, you need to install a pump that will work after the water overflows from the first compartment and reaches a certain level. In this case, the solid fractions will remain in the first section.

Tip! If the well is single-section, then a submersible sewage pump with a grinder is installed.