Septic mole: device, characteristics

The presence of autonomous full sewage for living in a country house - the requirement of time and legislation. Conventional cesspools - the last century, they cause environmental damage to the environment. Modern local sewage treatment plants prevent contact of the waste with the ground, as they are completely sealed. Russian manufacturers present various types of septic tanks in terms of volume, processing technologies, and materials. The AquaMaster Company from the Kirov region has developed a line of mobile autonomous purification systems made of polymeric materials - the Mole septic tank.

Model overview

Local treatment facilities of the Mole brand fully meet the environmental and technical requirements of the SNiP. They are a fully sealed container made of low-pressure cold-resistant polyethylene. The wall thickness varies from 7 to 14 cm. To give the structure greater rigidity so that the sump does not crush or lead, the septic tank is reinforced with stiffening ribs 15 cm in size. It is completely buried in the ground to the level of the inspection hatch. However, it should not be subjected to heavy loads from above after installation.

Flat bottom gives stability to the structure. The hull shape can be round or oval depending on the model. Septic Moles are:

- vertical;

- horizontal.

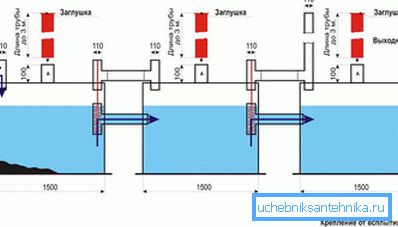

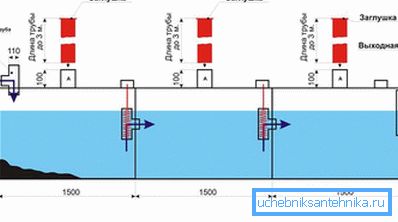

By the number of sections in the case drives can be single-chamber, two-chamber and three-chamber.

Depending on the number of people living and the required volume of waste processing, a housing of the required volume is selected. The smallest version - single-chamber, with a horizontal housing and a volume of 1.17 m3. If it is required to process a larger volume, then the horizontal models are combined with each other with the help of overflow pipes. Formed multi-chamber septic tank with several cleaning steps.

Vertical septic tanks can contain from one to three chambers with a capacity of 3.6 m.3, 3m3, 2.4 m3.

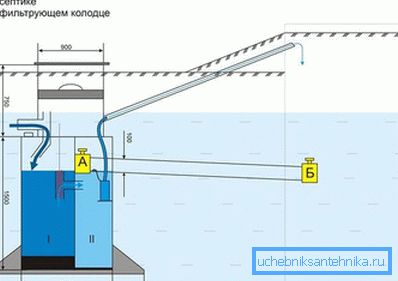

Mole can solve several problems. It can be used as a storage tank for collecting wastewater, which will later need to be removed by an after collecting machine. Multi-chamber designs resulting from the connection of several single-chamber models give a degree of purification of the liquid component of about 65%. That is why filtration through the drainage system is required.

Mole models are not limited to the standard version. The company at the request of the customer can make a septic tank with any arrangement of sewer branch pipes. This allows you to design a local cleaning system for the customer's project. All models can be equipped with pumps for forced pumping of waste from the system.

An optional K-module can be ordered as standard for the initial filtration of heavy fractions, fats and various oils. When filling with heavy fractions, the module should be periodically cleaned, after about 2–3 months. Content is easily processed by microorganisms, worms, turning into fertile soil.

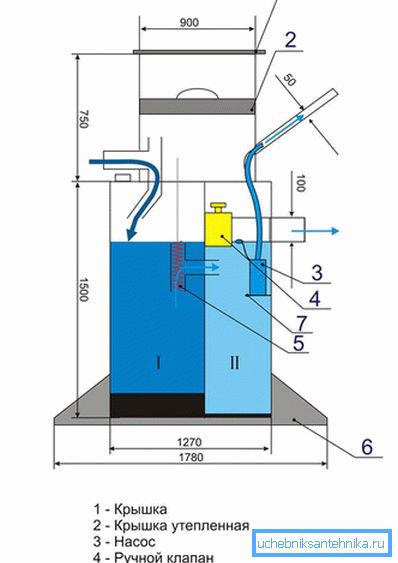

Internal organization

The drive device is simple. A single module can be divided into 2 or 3 cameras. Chambers represent a single integral design. There are extensions on the bottom outside, due to which the septic tank clings to the ground and does not float when the groundwater is high. This method of protection against ascent does not require any special fixings.

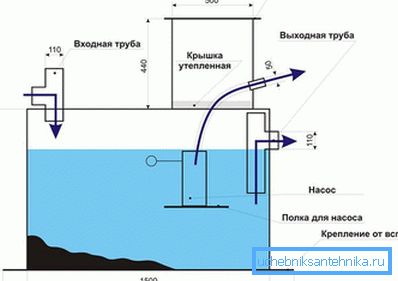

Inside is a shelf for the installation of a drainage pump for pumping drains if necessary. There are inlet and outlet pipes. They are already installed and sealed. If desired, you can install an additional inlet pipe through which liquid without solids will flow directly into the second chamber. In the multi-chamber version, a biofilter is installed in the first section, intended for bioprocessing and filtration of solid fractions.

The manhole has a height of 75 cm and a diameter of 90 cm. This is sufficient for maintenance and burial. There are two covers. The bottom cover is insulated. At will the well can be made other size according to the project of the customer.

With the help of a septic tank Mole, you can install an autonomous local sewage system with different functionalities: from the usual cesspool to a complete cleaning system that will last for decades. The principle of operation of single-chamber models is primitive. The sewer pipe receives wastewater, which is pumped out after filling the entire tank. Multichamber systems allow to process waste, dividing them into solid and liquid fractions, with the subsequent withdrawal of treated wastewater into the drainage system.

Merits

Benefits:

- High relative strength of a structure with stiffeners withstands ground pressure, including during heaving.

- Full tightness of the compartments between themselves and the entire module as a whole, which prevents environmental pollution.

- The design of the device does not require additional fastenings to protect against ascent in high groundwater.

- The wide well provides free access to the inside of the septic tank for its maintenance (filter replacement, pipe cleaning, etc.).

- Multi-chamber or multi-module designs do not require frequent pumping of sludge. The pumping frequency of an aspenizator machine is 3–5 years.

- A wide range of products, depending on the volume, number of chambers, the location of the module, the availability of additional elements and components, the ability to order designs for an individual project.

Disadvantages:

- Restriction in use. These systems are more suitable for seasonal residence in the country or permanent for a family of 1-2 people. For a family of 3-4 people a minimum of 7–8 m is required.3. These are 6–7 horizontal modules or 2–3 vertical ones.

- Increasing the number of modules increases the cost of equipment and installation services.