Septic tver: principle of operation, installation, operation

Comfortable accommodation is associated with a country house, a cottage in which there are all engineering communications: electricity, hot and cold water supply, heating and sewerage. But some communications do not have centralized support. Least of all suburban settlements, villages, country communities are provided with a central system for the collection of sewage.

The solution to the problem of disposal and cleaning of sewage can be solved using a local cleaning system. The widespread development of the use of special equipment is caused not only by the generally accepted trend, but also by the norms of legislative regulation to ensure the environmental safety of the environment: soils and sources of drinking water supply. Domestic manufacturers offer autonomous sewage systems of various types in terms of functionality and degree of waste treatment.

Septic Tver is produced in Russia at the enterprises of the Trading House "Engineering Equipment" and has established itself from the positive side in different climatic conditions, requiring minimal maintenance costs.

Overview

The septic tanks of the Tver line are local autonomous systems of multistage sewage treatment from high-quality plastics. Different in size models are ideal for cottages, bathhouses, country houses, as well as industrial facilities in the absence of a centralized sewer system. The septic tank is capable of providing biological wastewater treatment up to 98% due to deep multi-stage processing. This allows you to use the purified water again for technical needs: to bring it into the ground, a reservoir without additional filtration and chemical treatment.

Operating principle

Purification of domestic wastewaters can occur mechanically (settling, filtration) or biological (processing of waste by microorganisms, bacteria). Biodegradation occurs under the influence of two types of bacteria:

- anaerobic, which for vital activity does not require oxygen;

- aerobic, which necessarily require oxygen.

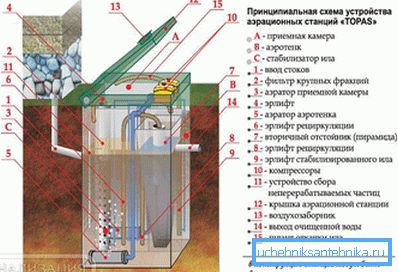

Deep wastewater treatment is achieved only with a combination of all types of processing. This is what distinguishes these septic tanks. Multi-chamber design, where mechanical cleaning takes place sequentially in each chamber, and then biological under the action of anaerobic and aerobic organisms. At the exit, purification from contamination reaches 95–98%.

In the first chamber, the settling of heavy fractions occurs, which settle at the bottom. Large heavy structures decompose under the action of anaerobic bacteria in an airless environment, resulting in non-degradable substances precipitated in solid sediment. After the initial biodegradation, light and liquid fractions of substances enter the aerobic chamber, where the final wastewater treatment process takes place. Water saturated with organic compounds is additionally saturated with oxygen. This is an ideal environment for aerobic bacteria, which ultimately purify water from pollution.

Septic tank is a single construction of polypropylene, divided by walls into several chambers. It is completely sealed, with the ends there are protrusions at the bottom to prevent ascent at high levels of groundwater.

The first chamber is septic. Wastewater from a sewer pipe gets into it, where the primary sedimentation of insoluble suspended matter occurs. Over time, the sediment partially decomposes under the action of bacteria, and the part of waste not exposed to bioprocessing accumulates and is removed as the chamber is filled.

The components that did not precipitate together with the liquid part of the effluent pass through an anaerobic bioreactor. Passing through this section, the components of sewage are subjected to mechanical destruction, due to the special elements of the chamber, resembling ruffs, and are partially hydrolyzed by anaerobic bacteria. In this chamber, fermentation occurs.

In the next chamber is an aerator. It nourishes the liquid component with oxygen. Aerobic bacteria multiply rapidly. Oxygenated effluents enter a septic tank where heavy suspensions settle and liquid waste enters the next biodegradation chamber.

In an aerobic reactor, wastewater undergoes two processes. Aerobic bacteria break down organic inclusions, absorbing them. At the bottom of the section is limestone, which in the water reacts with phosphorus and nitrogen compounds, which are toxic.

In the last chamber of the settling tank, the decontaminated water passes clarification due to precipitation. At this stage, the effluent is cleaned up to 98%. In the chamber are floats with chlorine-containing reagents. They disinfect the water that comes out of the septic tank.

Tip! A compressor for saturating wastewater with oxygen is not located in a septic tank, but in the back room of a house.

Advantages of the local cleaning system

Advantages:

- It has a full cycle of processing and treatment of wastewater inside the station without the need for additional filtration through drainage.

- The walls are made of high quality polypropylene, non-toxic, non-corrosive. The service life of the installation is several decades.

- High degree of purification - up to 98%. This indicator is achieved with proper selection of the volume and the required performance. Purified water can be used again for technical needs.

- Stations are environmentally friendly. Three types of sewage treatment with chemical disinfection of impurities help to effectively clean sewage.

- The design works by draining large volumes of effluent at the same time without loss of cleaning quality.

- Simplicity of a design and service.

- Ease of installation. Self-installation of a cleaning system is possible.

What should think

Disadvantages:

- Volatility. An aerobic chamber can work only when oxygen is saturated with water. Without electricity and oxygen supply, the septic tank can work without loss of quality of cleaning no more than a day.

- Relatively high price for a local wastewater treatment system.

- Fear of mechanical damage.

- Lack of stiffening ribs.

Installation

Autonomous cleaning system installed in the ground. Ditch digging taking into account the depth of freezing. The perimeter of the pit should exceed the dimensions of a septic tank by 200 mm. It should be installed on a horizontal sand pillow. After connecting the pipes, backfilling is done gradually. At the same time, the body is covered with sand in layers of 20 cm and filled with water to the level of weirs. If necessary, warmed.

Read also reviews of the following septic tanks:

- Mole

- Flotenk

- Yunilos Astra

- Cedar

- Sunrise