Wastewater treatment methods: biological, chemical

Sewage is overflowed with various chemical means, for example, detergents, powders. Because of this, there is a need to clean them. To purify wastewater from various pollutants: mechanical components and chemical compounds - carry out multi-level treatment.

Methods can be recuperative and destructive. Under the action of the destructive method, complex composite components are decomposed into simple ones. They are removed from water as gas or simply precipitate, which, in turn, does not cause either passive or active harm to the environment. As for the recovery method, valuable substances are extracted from the effluent for further processing and processing.

It is important to find out how and how wastewater is treated. The following are the main methods of this process:

- Mechanical cleaning.

- Biological cleaning.

- Physical and chemical cleaning.

- Disinfection.

- Thermal disposal.

Now consider some of these methods in more detail.

Biological cleaning

The principle of biological wastewater treatment is the vital activity of microorganisms. They contribute to the process of oxidation or the reduction of organic matter that is currently contained in wastewater. Biological products produced in the form of a solution, colloids or suspensions. Biological treatment plants are of two types:

- Structures in which the cleaning process occurs in as close as possible to natural conditions.

- Structures in which the cleaning process is carried out in artificially created conditions.

As for the first type of treatment, these are structures in which the process of filtration takes place by means of the soil, as well as structures that are small water bodies with running water. They create conditions under which microorganisms can absorb oxygen. In the structures of the second type, the process of respiration of microorganisms is carried out due to diffusion through the surface of the water (re-aeration) or mechanical aeration.

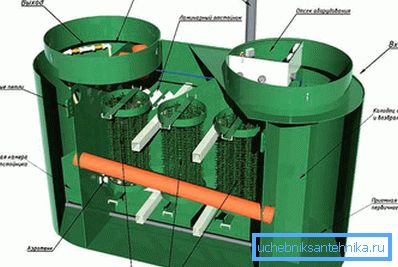

In this case, biological treatment takes place in aerotanks, biofilters, as well as in aerofilters. Under these conditions, the cleaning procedure is more intensive. This is due to the fact that ideal conditions are created for the vital activity of microorganisms.

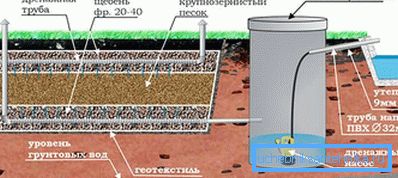

If more serious requirements are imposed on the quality of wastewater treatment, then in this case additional water purification is carried out by means of a sand filter, which can be multi-layered or two-layer.

So, biological treatment is carried out exclusively by two methods, namely:

- aerobic microorganisms (they need oxygen for their vital activity),

- anaerobic microorganisms (for their life does not need oxygen).

Now let's take a closer look at the first cleaning method.

Bioprud

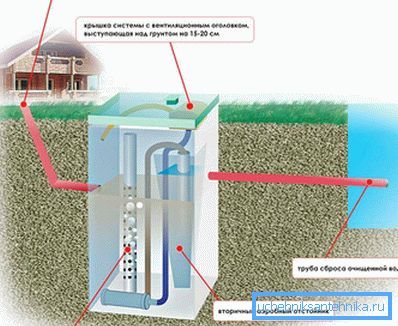

It should be noted that the treatment of wastewater by this method is determined by several types of capacity. The oxidation process is carried out directly in these tanks. As mentioned above, this can be a special installation - a biopond or a self-made biological filter (cleaning with soil). Thus, the filtration fields mean by themselves specially made areas that are intended to discharge waste into them.

When the effluent enters the soil, a process takes place in which biological compounds undergo oxidation, resulting in their decomposition into carbon dioxide and water. However, in addition to this, parallel to the process of synthesis of the biomass of bacteria, which is known as organic processing, takes place.

Bioponds contain a huge amount of algae, which fill the water with oxygen. These are ideal conditions for the life of microorganisms. Ponds have a shallow depth. Such facilities are used to clean industrial effluents, as well as to clean rivers that flow into the reservoir. However, bioponds have one major drawback. It is connected with the fact that this method is seasonal, it is characterized by low productivity, as well as the need for a large area of land.

Among other things, artificial structures are widely used, which clean sewage by biological method. These structures allow microorganisms to live and multiply for a long time. They regularly maintain a certain temperature, oxygen concentration, pH, and the like. This technology imitates cleaning through the soil, i.e. by natural method. One of these structures is the aero tank.

Aerotenk

In this case, a capacity is applied, which can reach a depth of six meters. It is equipped with a special device that forces air into the tank. This creates a suitable environment for the life and prosperity of microbial colonies on flakes of silt. Then the water enters a special sump. It is carried out another process - decanting. Some particles are returned to the tank for disposal.

Biological filter

This container is filled with a special coarse-grained material. It is inhabited by colonies of microorganisms. Unlike aerotanks, the biological filter is much easier to maintain. It is more reliable, able to cope with the increased volume of incoming wastewater. However, there is one thing but! If you do not observe a certain concentration of pollution, then microorganisms will simply become extinct.

In the case when organic matter of high concentration is present in the effluent, an anaerobic reactor cleaning method will be a suitable option.

Anaerobic reactor

This tank is made of metal. The lifespan of anaerobic microorganisms is regulated by the release of methane into the air. Special equipment is installed that monitors its level, otherwise the microorganisms will become extinct.

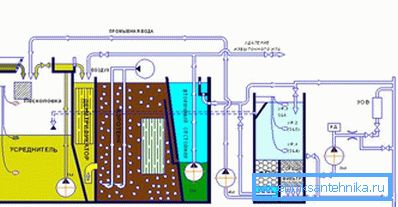

All these methods are relevant in the event that the concentration of certain polluting agents does not exceed the permissible minimum. In most cases, in order to achieve the highest quality result, drains pass through up to four cleaning stages. And before the sewage is discharged into the reservoir, the tertiary treatment by ozonation occurs.

Mechanical cleaning

This type of cleaning is a preliminary stage. The main goal is water purification from suspended or precipitated fibers, insoluble solid elements, as well as coarse impurities. These can adversely affect the filters.

If wastewater is planned to be reused as industrial water in the future, then there is no way to do without mechanical cleaning. Moreover, with its help you can get rid of all sorts of chemical compounds. Filtered compounds can be reused in a particular production. As a result, it is possible to reuse industrial water, which contributes to the return to the cycle of a certain amount of raw materials.

Mechanical treatment neutralizes toxic wastewater compounds. And most importantly, this is achieved by replenishing stocks of pure natural water. It is necessary to take into account the fact that today there are several types of equipment that is used for mechanical cleaning. In each case, an individual approach is required, since certain drains may contain suspended particles of different sizes. There are several simple and effective technical solutions for mechanical cleaning.

Straining

In this case, water flows through special grids and grids. They, in turn, have cells of a given size. In most cases, gratings and nets made of metal are used. The size of such cells must be such that they can hold certain particles of different sizes. For high-pressure cleaning, high-strength meshes and gratings are used. The use of such facilities will allow high-quality cleaning of drains, as well as increasing the productivity of the structure.

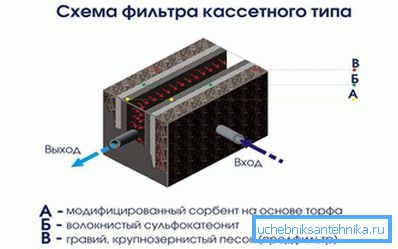

Filtration

In this case, the water passes through a special backfill or porous material. Water can be either under pressure or without pressure. Sand, particles of glass, metal are used as fillers. Among other things, by means of filtration, finer purification can be achieved. It all depends on the filler.

Upholding

This process is accompanied by gravitational precipitation, as well as separation of fractions. This installation is a series of cameras equipped with overflows, in which particles settle under the action of gravity. The top layer of purified water is poured into the next chamber. As soon as the second chamber is filled to the appropriate level, the cleaning process is repeated. One of such simple and rational gravity sedimentation tanks is a sand catcher. The process of settling water occurs within a few hours. This period is completely dependent on the level of contamination of the effluent.

So, these are the simplest methods of mechanical cleaning that can be used even at home. More complex solutions are used for industrial purposes.

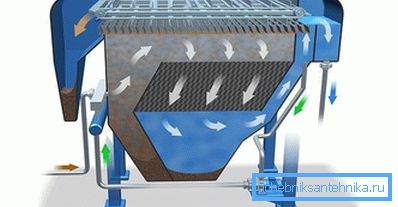

Disc filter

This unit, which is a cylindrical package consisting of polymer discs. They have a specially treated surface, thereby forming a three-dimensional structure. As a result, water is perfectly purified from mechanical impurities. This equipment is quite simple to use, characterized by high reliability. If the disc filter is very dirty, it is very easy to clean it, and there is no need to purchase additional consumables.

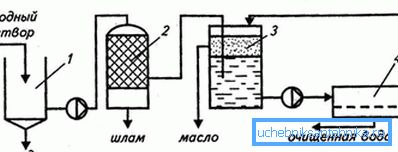

Flotation

This technology is used in most cases in oil refineries, food and chemical industries, as well as in the metalworking industry. Gas bubbles pass through the liquid mass, as a result of which they trap contaminated particles and lift them up. As a result of this action, a foam appears on the surface, which is simply removed. How to launch gas bubbles? To do this, use the method of electrolysis or aeration. In order to increase and guarantee the success of the flotation purification method, coagulants can be used additionally. They accelerate the process of raising the sediment to the surface and, accordingly, its removal.

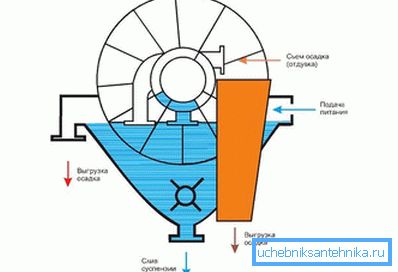

Hydrocyclones or centrifugation

This physical phenomenon separates the fraction of solids in a constant flow process. This efficient and high-speed process can be performed automatically. In parallel, several centrifuges can operate at once, which have a large capacity. The speed of separation in the course of this cleaning in a centrifugal field can be several times greater than the speed of the precipitating equivalent particles hundreds of times.

In each case, an individual method of purification from insoluble contaminants is chosen. As a result, it is possible to achieve a reduction in the cost of subsequent cleaning, as well as the protection of household equipment from breakage as a result of interaction with solid particles.

Heavy metal cleaning

Some industrial enterprises in the course of their activities have wastewater that contains heavy metal ions. Such drains should be deep cleared. It allows you to reduce the concentration of toxic living organisms in the liquid, which merges into water.

There are a large number of such methods. For example, the method of neutralization, which implies an increase in pH to ten. Accordingly, when an excess of OH- ions appears, which just as a result of the increase in the pH value occurs, the process of molarization of heavy metal ions is carried out. In this case, they precipitate as hydroxides. However, as practice shows, this neutralization method reduces the level of the indicator of heavy metals to not less than a tenth of a milligram per liter, so you need to carry out additional treatment. To do this, you can use the following technology.

For purification, a reagent-precipitant is used, which contains sulphide compounds. At the same time there are a large number of reagent groups, which in each individual case have their own unique technical characteristics.