Waterproofing septic tank of concrete rings

In our article, we will tell you about how a septic tank is waterproofed from concrete rings, as well as a number of requirements for the quality of the work carried out in this case.

Ways

In essence, the waterproofing of a reinforced concrete clarifier is a set of technical measures for the protection of concrete billets from the effects of corrosive media, implemented with the help of special insulating materials.

For waterproofing concrete ring structures, a variety of techniques can be used to ensure high quality sealing and to reliably block any leakage of wastewater. The most popular among ordinary consumers are the following methods:

- use of bituminous mixtures;

- penetrating waterproofing;

- the use of plug-in plastic rings with subsequent sealing of the seams with silicone;

- polymer cement waterproofing method.

Consider each of these techniques in more detail.

Bitumen application

Molten bitumen, despite its excellent insulating characteristics, is a short-lived material that can flake and collapse with significant fluctuations in temperature. That is why, when processing concrete rings, bitumen is used in conjunction with bitumen mastics containing special additives.

Before processing, the inner and outer walls of the concrete rings are thoroughly cleaned of dirt, after which a layer of bitumen mixture with gasoline (in a 1: 3 ratio) is sprayed onto them using a compressor. After it dries with a brush or kvach, a second and then a third layer of bitumen mixture with gasoline is applied (in a 1: 1 ratio). On top of the cooled coating is applied a layer of mastic with a thickness of at least 3 mm.

In conclusion, roofing material or similar insulating material is stuck on the outer wall of the reinforced concrete ring.

Tip! The advantages of the bituminous method of sealing should include the relatively low cost of the material and ease of installation work. Despite the indisputable advantages of the traditional method of insulation, one should not forget about modern materials, the use of which can cost a little more than traditional ones, but it will provide high reliability of the insulation coating.

Penetrating waterproofing

The method of penetrating waterproofing is considered the most reliable way to seal the reinforced concrete rings, providing deep penetration of the applied material into the pores of the concrete with simultaneous filling of all the voids in it.

To implement this method, special penetrating compounds of industrial production are used (Penetron, Lakhta, Hydro S, etc.). After treatment with these materials, a homogeneous structure is formed on the inner and outer surfaces of the concrete rings, which can protect them from the effects of aggressive media for a long time.

It should be noted that before using such materials, the surfaces to be treated are thoroughly prepared for the coating, including complete cleaning of the walls, as well as chemical (using special chemicals) and mechanical processing of concrete.

Polymer cement protection

The relatively inexpensive and widely used waterproofing methods include the so-called coating or polymer-cement protection, realized through the use of cement mixtures with special polymer additives (including liquid glass).

Like the bitumen insulation method, polymer-cement protection is notable for its simplicity of implementation, but, unlike it, it has a longer service life.

Plastic inserts

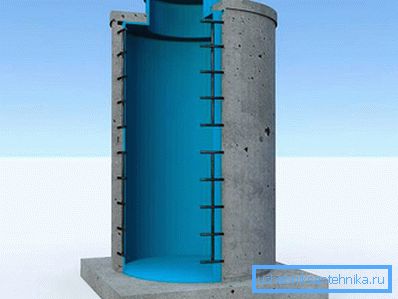

The use of plastic cylinder inserts of various sizes is a simple and guaranteed reliable method of waterproofing. To implement it, you will need special inserts of the appropriate size (the industry produces cylinders up to 4.5 meters high and with a diameter of 90, 140 and 190 cm), equipped with a neck with a cover.

Tip! After being inserted into concrete rings, the cylinders are fixed in them with the help of a dry cement-sand backfill.

Sealing seams

Regardless of the method you choose to protect the septic tank, special attention is always paid to the reliable sealing of the ring seams. For these purposes, special shock-absorbing and waterproofing gaskets made of modern materials are usually used (rubber sealing tape "Rubber Elast", for example).

From traditional and relatively inexpensive materials used to seal the seams, you can select jute, flax or hemp fibers, impregnated with liquid fibrous rubber. In the process of sealing the rope of these fibers are usually laid on a layer of thick polymer.

Video

This video shows how a waterproofing test was performed on a concrete ring: Raberit:

This video demonstrates how to eliminate water leaks between concrete rings: