40 to 40 shaped tube: technical specifications and

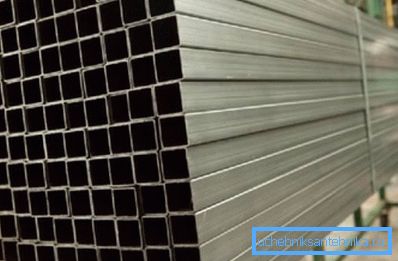

Steel profile pipe 40x40 mm has many unique advantages, allowing to apply it in a variety of areas. In most cases, it serves to create frames of various structures or even buildings. But let's talk about everything in more detail.

Character traits

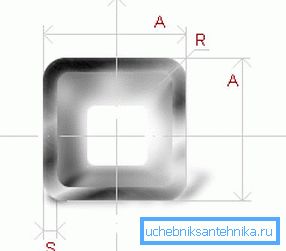

The range of the product under consideration is regulated by GOST 13663-86 and 8639-82:

Technical details

| Parameter | Possible values |

| Manufacturing material | Different steel grades: Steel 1, Steel 2, Steel 3, 09G2S |

| Section shape | Square |

| Size of section side | 40 mm |

| Wall thickness | 1-6 mm |

| Length | 1.5-12.5 m; distinguish products of dimensional, unmeasured and multiple measured length |

According to the method of manufacturing a professional pipe 40 40 can be of the following types:

| Metal processing method | The corresponding pipe name | Presence of seam |

| Cold forming | Cold rolled | Missing |

| Hot deformation | Hot rolled | Missing |

| Welding sheet metal | Electrowelded | Present |

Profile pipe 40 40 weight per meter:

| Wall thickness mm | Weight, kg |

| one | 1.21 |

| 2 | 2.33 |

| 3 | 3.36 |

| four | 4.3 |

| five | 5.16 |

| 6 | 5.92 |

Merits

- Very high strength. Due to the square shape, any mechanical impact falls not on the middle of the product, but on its stiffeners, capable of withstanding enormous loads. It is this quality that is most conducive to the use of shaped tubes as structural elements of buildings and other construction objects.

- Relatively light weight. So, for example, the weight of 1 meter of a 40x40x2 profile pipe is much less than that of an I-beam, which performs similar functions in the implementation of various architectural projects. This feature allows you to do without strengthening the foundation.

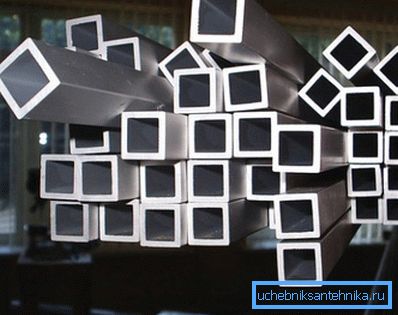

- Convenience of storage and transportation. Folded squares are much more stable and compact than circles.

- Optimal size. There is a large profile tube 140x140 mm, which has its own specific purpose, and, conversely, a small 15x15 mm, but the most popular is the section 40 by 40 mm.

- Easy to do it yourself. The flat sides are easy to fasten with bolts or welding, and the product itself fits comfortably in the hand during installation.

Tip: if you are using galvanized pipes, it is recommended to stop on the choice of bolts as a connection method. Welding can also damage the zinc layer, which will create vulnerable spots for corrosion damage.

- Affordable price. Relatively simple manufacturing process ensures low cost.

- Durability. The construction created from steel shaped pipes will serve you for many years.

The disadvantage and ways to overcome it

The negative side of the products under consideration derives precisely from their unprecedented strength. The stiffeners will not allow you to bend the profile pipe as easily as you would do with a regular round. But this task is required to be performed infrequently, usually only when installing arched structures.

If, however, you still need to perform this task, then the following instruction will help you, offering a choice of three ways of giving a rounded shape to the pipe:

- Machine. The easiest and most difficult method at the same time. Simplicity is the least effort, and the difficulty is that the necessary equipment still needs to be found, which is not so simple.

- "Bulgarian". The essence of this method lies in the application of cuts at the site of bending, breaking the solidity of the ribs. After creating the desired shape, they should be brewed.

Tip: when working with the "grinder" be sure to wear safety glasses to avoid scale in the eye.

- Sand. The use of sand is the most economical because it does not require expensive tools:

- We insert a stub from one side.

Tip: It is recommended to use a wooden cap, as it is easier to blast it out if you fail to pull it out.

- Fall asleep river clean sand.

- Tightly cork the second side.

- Bend like a normal round product. Sandstone will distribute the load evenly, which will compensate for the hardness of the ribs.

Areas of use

In order to make it easier to understand the breadth of operation of shaped pipes with a side of 40 mm, let's look at examples of constructions implemented with their help:

- Greenhouses and arbors. Such garden buildings are not only reliable, but also quite aesthetic.

- Supporting elements of buildings. It is noteworthy that the light weight of the profile pipe 40 40 2 will significantly reduce the mass of the whole building.

- Fences and gates. Steel "skeleton" of the products in question can be sheathed with any material you like: polycarbonate, iron sheets, wood. As a result, you will get a beautiful and durable fence of your plot.

- Scaffolding. Working at height, it is very important to feel the reliability of the support under your feet, stiffeners and flat edges of the products in question will more than provide you with one.

- Stepladders Mobile and durable ladder is needed in every household. The pipe with a cross section of 40 to 40 mm is ideal for its implementation.

- Details of agricultural machinery. Mechanical engineering also actively applies shaped pipes.

- Furniture. Racks, tables, chairs, having the considered products as a skeleton, will serve for a long time and efficiently.

Conclusion

The profile tube of the section under consideration has many unique qualities. The most significant of them is the incredibly high strength realized due to the presence of stiffeners. Due to its advantages, this product is widely used in construction, engineering and furniture production.

The video in this article will provide your attention for consideration additional materials relating to the topic presented. Successful to you operation of profile products!