Asbestos cement pipe 400: product features and applications

Asbestos-cement pipe 400 mm in the national economy has been used for a long time, but before talking about such pipes, let's first understand what is asbestos-cement itself.

This composition is made on the basis of the natural mineral asbestos, which is magnesium hydrosilicate. For the first time, it began to be used for construction needs about 100 years ago and still enjoys well-deserved popularity.

This mineral is found in nature in 2 types:

- chrysotile or white;

- amphibole.

Until the middle of the last century, both of these varieties were used in the construction industry, but it later turned out that the material based on amphibole is harmful to living organisms. After that, all over the world, ecologically neutral chrysolite asbestos is used exclusively.

What is good asbestos cement and what are its cons

- The material is quite high strength.. It is able to withstand a load in the range of up to 90 MPa, while the stability of structures on bending is about 30 MPa.

- The next positive point is the relatively low weight of the structures.. For example, a steel pipe will be at least one and a half times heavier.

- Asbestos cement or as it is also called fibrobeton, in comparison with the metal, has a much lower thermal conductivity. Due to this valuable quality, it does not require the arrangement of enhanced thermal insulation.

- The fibrous structure of the material gives it a good frost resistance. Such structures are able to withstand at least 50 cycles of freezing and at the same time the loss of strength will be no more than 10%.

- If the assembly instructions were strictly followed, then fiber-reinforced concrete pipelines can last up to 50 years without major repairs..

- And finally, the question that often interests the customer most of all is the price of the material.. The cost, of course, can vary depending on different circumstances, but the indisputable fact is that asbestos-cement structures are 3-4 times cheaper than metal structures.

- To all the above, you can also add relatively simple installation of structures.. Having at your disposal a complete set of materials and preferably 1 - 2 assistants, you can equip the pipeline in the country with your own hands in 1 day.

As you know, in our world there are no perfect materials, there are drawbacks to asbestos-cement:

- The unpleasant point is the susceptibility of the material to an acidic environment. Under the influence of acid, the walls of the products are stratified and become unusable. Modern chrysotile cement pipes, due to additives, can resist an acidic environment for some time, but such operation is not recommended.

- Another significant drawback is that these structures can only be straightforward. Cast iron or plastic adapters are available for arranging corner joints, but the asbestos-cement pipe itself does not bend.

- Although the fiber-reinforced concrete material is strong, but unlike the metal it does not deform upon impact, the wall of the product simply bursts.

Important: the quality characteristics of both pipes with a cross section of 400 mm, and other types of structures are governed by several regulatory documents, the main of which is GOST 31416-2009.

Subtleties of production and installation

The production technology of this material has been developed for a long time and over the years it has only been improved. The cost here is small, as well as the installation of their own hands, is not very complex.

How do the pipes

It all starts with the fact that asbestos itself passes through special crushing units. The mineral consists of fine fibers, and the process of crushing aims to separate these fibers, bring them to a friable state. The structure of the fibers resembles a fiber, hence one of the names of the material - fibrobeton.

After that, the fiber obtained in this way is mixed with cement in the dry state, and special seals and additives are added. When the dry mixture is ready, the liquid component is added to it and the solution is kneaded.

The solution is laid in special drums. The rotation of the drums occurs at high speed. According to all the laws of physics, centrifugal force evenly distributes and compacts the composition to the desired consistency. Next, the pipe passes the process of drying and technical control.

Important: pipes of large diameter, which is the diameter of 400 mm, are made of thick-walled. In addition to traditional cement and fiber, special compaction additives are mandatory added there.

Purpose of products

Designs can be produced in both round and rectangular sections, of course, round products are the most popular. But more attention is paid to quality characteristics depending on the purpose. Pipes are pressure and non-pressure.

If you believe the manufacturers, the pressure structures can withstand the internal pressure in the system up to 50 atm, which is quite enough for laying urban water lines, the pressure in which does not exceed 12 atm.

Important: all pipes of large cross section are available for pressure systems. The size is counted from 200 mm, hence we conclude that the product with a cross section of 400 mm can only be intended for pressure pipelines.

Non-pressure pipe structures are used for laying gravity water pipelines or communications designed to protect cable lines and other similar systems.

A few words about the installation

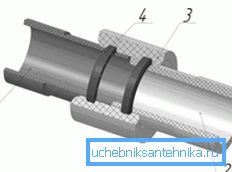

As already mentioned, constructions can only be straightforward. Connect products using couplings. In the past, for the manufacture of couplings used cast iron or the same fiber-reinforced concrete. Now they have been replaced by better and cheaper polymer constructions.

The instruction is simple, the pipe is inserted into the sleeve, rubber seals are used for sealing, plus bitumen or other special coating. It is recommended to conduct the gasket in the underground way in order to avoid mechanical damage. When laying underground, a sand cushion is made around the line with a thickness of at least 50 cm.

The video in this article provides more detailed information on asbestos-cement pipes.

Conclusion

A thick-walled asbestos-cement pressure pipe with a 400 mm section is distinguished by enhanced performance characteristics. In addition to plumbing systems, it has worked well in the construction of chimneys and pillar foundations.