Boiler tube as a key element of the equipment of heat

Internal and chimneys for boiler rooms are quite specific designs. A characteristic feature of most of them is the absence of a weld, which provides a significant increase in resistance to internal deformations.

Below we describe the most common features of such pipes, as well as give recommendations for their use in the arrangement of boiler rooms.

Product Overview

Main types

Today, two types of pipe products are referred to as boiler pipes:

- Materials that are used for the installation of internal piping steam installations.

- Products intended for the arrangement of smoke exhaust systems.

At the same time, regardless of the destination, more often such parts are manufactured using seamless technology. Due to this, the internal structure of the material of the walls retains homogeneity; there are no zones of internal stress in it, which allows the pipe to withstand strong heat and considerable pressure.

According to the production method, the following types are distinguished:

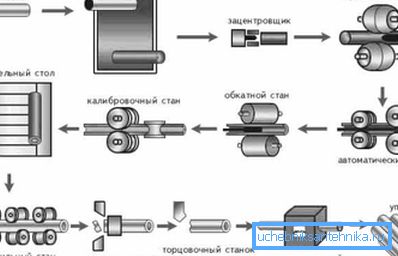

- Drawn products. For their production is taken from the durable steel billet, which is processed on a special machine. In this case, in one pass, the cross-sectional area can be reduced by 80-90%, which allows pipes to be produced with minimal labor costs. The final stage is the alignment of the ends and the final calibration.

- Hot rolled. Made from solid cylindrical blanks by flashing on special presses. The result is a hollow sleeve, which is then machined on a rolling mill until the internal diameter and wall thickness are brought to design values.

Note! There are restrictions on the size of hot-rolled products: outer diameter of at least 20 mm, wall thickness - 2.5 mm and more. However, for the equipment of boiler rooms more massive parts are most often used.

If we take into account the purpose, the pipe products of this group can be divided into:

- Low pressure boiler house - thick-walled pipes obtained by cold or hot deformation and used at low pressures and temperatures.

- Fin - hot-rolled or cold-drawn parts with side reinforcing ribs, oriented to work in conditions of high pressure. It should be noted that for such products put forward much more serious requirements for strength, respectively, and the price they will be much higher.

Regulatory documents and nomenclature

Internal piping, heating units and even the chimney of the boiler house are structures that are experiencing very serious operating loads. That is why the production of parts for their installation can be carried out only in strict accordance with the regulations (see also the article Viniplast tube - features and scope).

As such documents are the technical conditions:

- TU 14-3-190-2004 - seamless steel structures for thermal installations and their pipelines.

- TU 14-3-460-2009 - updated version of the previous document.

Note! In addition to the above standards, professional pipes may mention boiler pipes TU 14 3P 55 2001. Their use in the installation of steam equipment and pipelines is also permissible, since these products withstand pressures up to 95–98 MPa and temperatures up to 5000WITH.

The manual strictly regulates the dimensions of parts and tolerances. Below we provide a table that lists the main parameters by which the compliance of pipes with standards is determined:

| Production technology | Diameter, mm | Wall thickness mm | Tolerance | |

| by diameter | wall thickness | |||

| Hot deformation | 32 - 325 | 3.5 - 40 | one% | 5 -10% |

| Cold deformation | 10 - 76 | 2 - 12 | 0.3 - 0.8 mm | ten% |

Note! Usually delivery is carried out on the outer diameter of the product. In some cases it is possible to manufacture parts according to the internal diameter (subject to prior approval).

The color marking of the parts depending on the steel grade used is also quite common.

Paint the appropriate shade on the pipe ends:

- Green - 20.

- Blue-20PV.

- Red -12x1mf.

- White - 15H1M1F.

- Blue - 12H2MFSR

- Yellow - 15XM, etc.

The study of this marking facilitates the selection of elements during installation of the system.

Use of chimneys

Design features

In addition to the internal equipment, an important part is also a chimney, which is mounted on a thermal installation. The efficiency of the entire system depends on how accurately the calculation of the boiler chimney was carried out and how correctly this structure was installed.

There are several types of such pipes:

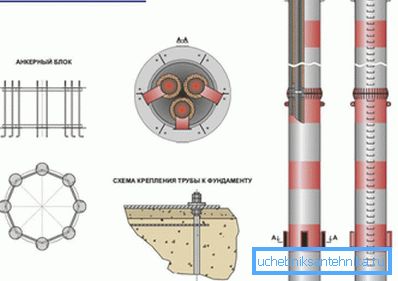

- Farm. The internal chimney is attached to self-supporting steel trusses installed on the ground and secured with depth anchors or an anchor basket in a monolithic reinforced concrete base.

- Self-supporting. They are assembled from several chimneys surrounded by a heat-insulating circuit and fixed inside a steel self-supporting shell. The external structure carries a static load and also resists wind stress.

- Facade. The most simple to install, some of them can be installed even with their own hands. Represent a prefabricated or monolithic steel chimney, mounted either directly on the wall, or on a system of wall brackets.

- Mast. As a smoke duct, a seamless thick-walled steel pipe is used, the lower part of which is fixed by anchors on the basement plate. To resist wind loads, the structure is fastened with braces of cables.

Note! Mast chimney can also be equipped with a heat-insulating protective cover.

It should be noted that most of these structures have significant dimensions and weight. That is why the installation or disassembly of the boiler tube is carried out mainly by specialized organizations. The only exceptions are small chimneys of private houses, as well as the small facade systems mentioned above.

Calculations of the main parameters

For the design and construction of an efficiently operating chimney, it is necessary to calculate in advance its basic parameters, which include the height of the boiler chimney and its internal diameter. The easiest way to do this is with the help of special calculator programs that can be found on the web, but even without them you can find out at least approximate numbers.

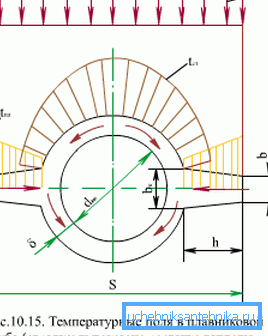

Note! In addition to these figures, it is also necessary to determine the mechanical characteristics of the structure and thermal parameters (temperature distortion, degree of heating of the casing, insulation thickness, etc.)

For household boilers of small capacity, the source data will be about the same:

- Gas inlet temperature - up to 2000WITH.

- The movement of gas in the pipe - 2m / s and more.

- The height of SNIP is at least 5 m from the grate and not less than 0.5 m from the ridge (for industrial models - at least 5 m higher than the tallest object within a radius of 25 m).

- Natural gas pressure - 4 Pa and more.

As an example, we calculate the diameter of a steel insulated pipe (thermal coefficient B = 0.34) required for operation of a boiler room, in which 10 kg of firewood with a humidity of 25% and an outlet temperature of 150 are burned per hour.0WITH.

The volume of gases required for combustion of fuel - 10m3/ kg:

- We calculate the volume of gases at the inlet to the pipe per second using the formula Vr = m * V * (1 + t / 273) / 3600, where m is the mass of fuel and V is the volume of gas.

- We get Vr = (10 * 10 * 1.55) / 3600 = 0.043 m3/with.

- Using the formula for the volume of the cylinder, we determine the square of the diameter D2 = (4 • 0.043) / 3.14 • 2 = 0.027.

- Consequently, the minimum diameter of the chimney will be 0.165 m.

As you can see, the calculations of even one parameter are quite complicated. This is another argument in favor of the fact that the design of chimneys, especially designed to support the operation of high-capacity boiler houses, should be handled by professionals.

Lightning protection

Taking into account all the features in the preparation of the project, proper installation, regular inspection of boiler chimneys to detect defects and their timely elimination are essential conditions for effective work. However, sometimes the cause of system failure can be external factors.

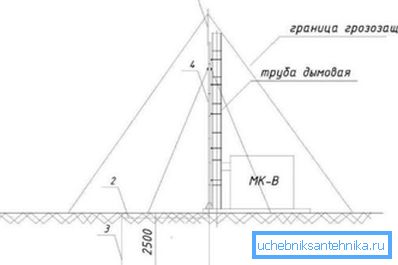

One of these factors is lightning, and therefore high pipes must be protected from its impact:

- On non-metallic chimneys mounted steel or copper-coated lightning rods. Their number can vary from one (structures up to 50 m) to three (from 150 m and above). In some cases, the rods are replaced with steel ring plates, which are mounted on the end.

- For concrete pipes, the role of lightning conductors is played by the internal reinforcement. To improve the efficiency of its operation, the upper edges of the rods are welded together.

- The steel pipe itself plays the role of a lightning conductor. Naturally, in this case it is important to provide high-quality grounding.

Conclusion

The design of chimneys of boiler rooms, as well as the selection of elements for the formation of heat-carrying circuits should be carried out only after fundamental theoretical training. To begin with, we recommend studying the algorithms and video in this article, however, you should not begin to work without proper practice: the risk of error is too great, which can significantly impair the functioning of the system (see also Cold-Deformed Tubes: standards and production technology).