Casing installation in the well

The task of ensuring uninterrupted water supply has always been one of the priorities in human life. In urban conditions, this issue is probably not so acute, but if we are talking about private households, setting up your own well is a rather desirable and at the same time crucial step. That is why all its stages should be treated with due attention. For example, installation of a casing pipe in a well is a task far from simple and at the same time responsible. The main aspects of the implementation of the above process will be discussed further.

Description and Purpose

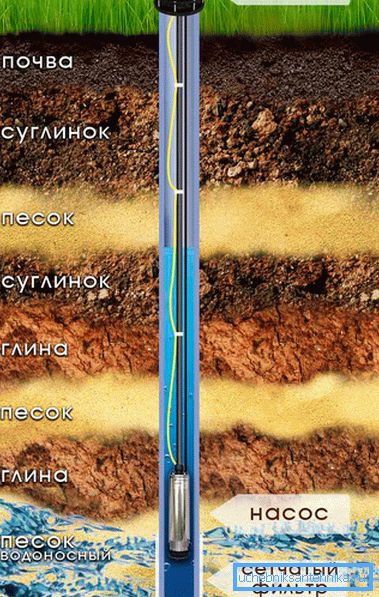

In order to better understand the essence of the upcoming works, we should first say a few words about what casing pipes are and for what purposes they are used. The bottom line is that over time, inevitably there are ground movements. This may be seasonal or may be due to the nature of the soil structure. However, this also happens in order to prevent the well from falling asleep as a result of this process, casing pipes are installed inside it. In fact, this element of the plumbing system assumes all the load that occurs when the ground moves. This circumstance imposes certain restrictions with regard to materials suitable for the purposes mentioned.

Types of casing

As for the material that should be used to install casing, it should be said that a clear answer simply does not exist. The fact is that, in principle, several options are suitable for this at once, however, each of them has individual operational characteristics and in order to make a choice, you must consider each one separately.

Tip! When selecting casing pipes, it is necessary to take into account that over time they may need to be removed.

Asbestos pipes

Pipes used as well casing can be made of asbestos. However, you need to know that this option has both undoubted advantages and some disadvantages. The number of positive qualities include:

- chemical neutrality;

- non-corrosive;

- availability.

As for the cons, we can mention:

- considerable weight;

- relative fragility;

- installation complexity;

- quite high price.

Metal pipes

Pipes made of metal can also be used as casing. This option has one significant advantage, which allows the use of such material in almost all cases, at any depth of the well, not paying attention to the characteristics of the soil. Metal pipes are very durable and with a certain thickness of the walls are practically not subject to mechanical stress. But the existing shortcomings can repel from the use:

- relatively high price;

- decent weight;

- propensity to corrosion;

- the need to use special filters;

- the possibility of equipment failure as a result of ingress of rust.

Well and, among other things, it is worth mentioning the very unpleasant metallic taste of water from such a well.

Plastic pipes

The most appropriate option in most cases will be to install a casing made of plastic. This material has the following characteristics:

- material strength;

- relatively light weight;

- relative cheapness;

- simplicity of work;

- chemical neutrality;

- resistance to water;

- durability.

But it is worth considering that this material is not without flaws, among which can be attributed to the impossibility of using it in wells that have a greater depth.

Installation

By and large, the installation of casing is not too difficult to implement, and you can do it yourself. It is worth knowing that this task alone is hardly solvable, and also the use of special tools will be required. If we talk about the works themselves, they are as follows:

- After the well has been dug into it (manually or with the help of technology, depending on the material), the first part of the pipe is placed.

- Lowering it inward until the moment when it remains about a meter above the surface, the segment is clamped with a special tool, similar to large tongs, and the second part joins it.

- Further, all other components join in the same way.

It is worth adding that there are several ways to connect pipes to each other. This may be a threaded connection, a connection through special clamps or a joint by welding. Deciding what to choose is necessary on the basis of the material used for the manufacture of pipes, and all joints need to be further treated with sealants.

In conclusion, it can be added that the installation of the casing is a rather simple task if you know how to do it, and therefore viewing the relevant videos is reasonably sufficient for the most complete understanding of the task.

Video

Installation of upsetting pipes PND:

From this video, you will learn which pipe cannot be used as a casing: