Casing: varieties and features of the application

Casing pipe PND or its steel equivalent is used to strengthen the walls of the wellbore. Immediately after the well has been drilled, it becomes necessary to use a casing (string). After the column is installed in the well, a cement or clay tamponage of the barrel is carried out.

And only at the end of this work, you can be sure that the well is optimally protected from floats, groundwater and other equally important risks. Let us take a closer look at how metal or plastic casing is used.

Application features

Modern casing for bored piles are sections of pipes that are rigidly interconnected. The thickness of the walls of the structure, as a rule, does not exceed 4 cm.

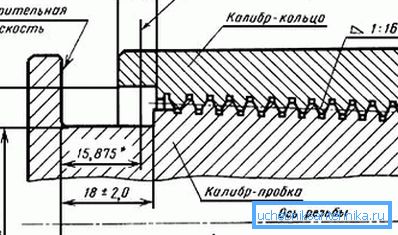

The connection of several pipes into a single structure can be carried out by means of pipe joints. To do this, the pipes are provided with a tapered thread with a triangular profile.

The intensity of penetration is determined by the diameter of the well, the operating characteristics of the drilling equipment, soil features, etc.

The use of casing provides the following benefits:

- the ability to work in water-saturated weak ground;

- the possibility of the horizon overlapping in floating soils;

- prevention of vibration and dynamic effects on the ground;

- securing the installation of piles;

- the possibility of installing piles in close proximity to already operated construction sites without compromising their integrity;

- lower cost of drilling and subsequent well operation;

- ensuring reliable well protection against collapse;

- ensuring optimal control of drilling until reaching the bearing layer;

- the ability to monitor compliance with the actual and design engineering and geological conditions directly during drilling;

- efficient drilling and extraction of boulders;

- efficient filling of wells with concrete.

Industrially manufactured casing for piles are of two types:

- casing modifications;

- core modifications.

Both categories are used to strengthen wells during their drilling and subsequent use. The product immerses the ground and does not allow unstable layers of rock to crumble.

Casing drilling is performed as follows:

- Drilled upper layers of rock;

- In the resulting recess is lowered and cemented column;

- Between the outer diameter of the column and the inner diameter of the well, concrete is poured in (less often, clay mortar is laid);

- After the concrete has gained sufficient strength, a pipe of a smaller diameter is lowered into the primary column and drilling continues;

- After the next pipe has taken the desired position, work continues again until the drilling equipment reaches the design depth.

Construction features

GOST casing pipe has a number of stringent requirements for these structures.

For example, despite the different wall thickness and configuration of columns, these parameters must comply with the limits set by the rules:

- If casing pipes according to GOST 632 80 are manufactured with standard accuracy, their non-straightness per 1 m with a diameter of up to 89 mm cannot exceed 0.7 mm and cannot be more than 1 mm with a diameter of up to 146 mm.

- If pipes of improved accuracy are manufactured, the non-linearity parameters should be no more than 0.5 mm for products with a diameter of up to 146 mm.

Instructions for the use of casing for wells depends largely on the material used in their manufacture. Modern products are made using iron, steel, polymeric materials, asbestos cement and wood.

Currently, the most widespread are constructions produced using polymeric materials, such as, for example, polyvinyl chloride (PVC).

Among the advantages of PVC columns are the following:

- lower price compared to metal counterparts;

- high strength compared to asbestos cement;

- absolute resistance to corrosion processes and, as a result, almost unlimited operational resource;

- resistance to mechanical stress up to 5 t;

- ideally smooth internal and external surface and, as a result, ease of use with your own hands.

Related materials and accessories

By itself, the column, no matter what material it is made from, is not able to cope with the tasks assigned to the front.

To ensure proper operational efficiency, a number of related accessories are used, among which we note the following categories:

- Cutter - is a cutting element, which is mounted on the knife section at the beginning of the pipe. By means of the cutters, the column is buried and positioned in the ground.

The casing cutter is manufactured using materials such as carbide steels or hard metals.

As a rule, steel is used in the manufacture of the head and the shank, which do not come into direct contact with the ground during the drilling process. Pobeditovye alloys are used in the casting of teeth that destroy the soil, and therefore should be characterized by high strength properties.

An important condition that must be met in the manufacture of incisors is the high quality of the teeth and head spikes.

Important: Most of the cutters produced today undergo pre-sales tests. During the tests, the spike is checked by shear mechanical load.

Modern cutters on the market are represented by two main varieties - removable and weld-on modifications.

The choice of one or another category of accessories is made in accordance with the peculiarities of the pipes used.

- Centralizer - used to give the casing string strictly perpendicular position and a uniform distance from the edge of the well along its entire perimeter.

Centering taps are an essential condition that ensures high-quality and efficient dusting of the column. Installation of centralizers on the pipes is made in increments of not more than 9 meters. Structurally, the device is a nozzle in the form of a coupling with spacer wings.

- The casing cap is a device that is installed on the well string to prevent soil and other foreign objects from sprinkling into their cavity.

The cover not only tightly closes the wellhead, but, depending on the modification, it can be equipped with a hook and a set of terminals for connecting and pursuing the operation of pumping equipment. Casing caps are most often made from aluminum or plastic. Both that and other variant shows the sufficient durability and tightness of a porch.

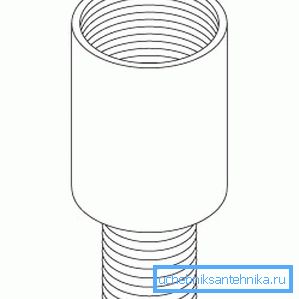

- Adapters are structural reinforcement designed for transition from a large diameter of the casing string to a smaller diameter of pipes in which the filtering part can be located.

- Mounting accessories - used for pipe installation. In accordance with the depth of the well, various tooling is applied, including lifting and lowering holders, lifting nozzles, etc.

Working with columns and filter elements with a diameter of not more than 30 mm, it is advisable to use belt wrenches for casing. Most often, the use of keys of the belt type applies to columns made of polyvinyl chloride.

Important: Flexible belt tightening allows you to grab the pipe with a round or oval cross section and at the same time not to deform it.

For simplicity and efficiency of use, the key of the belt type is equipped with a ratchet clamp, a nylon belt and a central prism support.

To work with casing pipes made of metal, it is customary to use a hinged key, which, unlike the belt analog, provides a tighter grip, but at the same time is unable to deform the steel.

Conclusion

Now you know what a casing is and how it is used for its intended purpose. Apply the information obtained can be practiced, for example, arranging an aquifer well at the dacha.

Do you have any questions to clarify? In this case, more useful information you will find by watching the video in this article.