Cast iron pipes and their features

Many believe that cast iron pipes are used only in sewer systems, and then, gradually, they are becoming a thing of the past. However, in reality, along with modern materials, they continue to be used in water and heat supply systems. Next, we consider the features of these products, their types and scope.

General information

Cast iron, as you know, is an alloy of iron, which contains in its composition a large percentage of carbon, as a result of which it is brittle. However, this quality is unacceptable in water supply systems, gas pipelines and other pipelines where high pressure is present in the system.

Therefore, the pipes are not made of the usual cast iron. The fact is that carbon can be in different forms and have different properties. For example, carbon black, graphite, and diamond are all different forms of carbon.

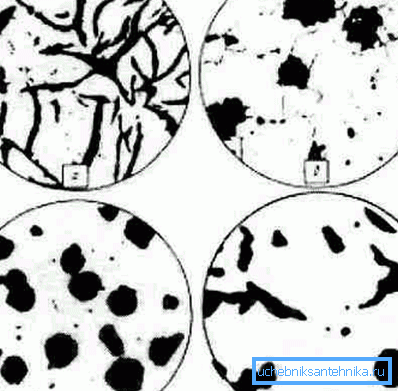

Graphite, which, together with iron and some other impurities, forms cast iron, usually has a lamellar form. If a small amount of magnesium is added to the composition, after which high-temperature annealing is performed, the particles of graphite will take a spherical shape. This change allows you to get a material with completely different properties, and it is precisely this that is used in the manufacture of cast iron pipes.

In particular, thanks to this modification, the material acquires the following qualities:

- It becomes much less fragile;

- In case of deformation, it can stretch without cracking;

- It becomes more resistant to aggressive environments and atmospheric oxygen;

- Its durability increases, which can be 100 years or more.

Due to this, products from such cast iron possess rather high operational qualities and are able to withstand high loads and negative environmental effects.

Performance properties

Among the performance qualities of cast iron pipes are the following points:

- Environmental friendliness.

- Corrosion resistance.

- High wear resistance.

- High tensile strength.

- Resistant to mechanical damage.

- Slight thermal expansion.

- The high level of noise absorption, so cast iron sewer risers are much more "quiet" than plastic.

- Resistance to temperature extremes.

- Resistance to fire.

- There are no seams, which increases the strength of products.

- The low price of the material, compared with steel pipes

Of course, cast iron pipes also have some disadvantages, the main of which are:

- Great weight. For example, the weight of a cast-iron pipe 100 mm in diameter is 25 kg (linear meter). This complicates transportation and installation.

- Complicated build process that takes a lot of time.

- The complexity of machining.

Tip! Often in front of the house craftsmen there is a need to cut the pipe, for example, when dismantling the cast-iron sewer riser. For these purposes, it is best to use the grinder. However, before cutting the cast-iron pipe, you should make sure that the circle installed in the grinder is intended for cutting metal.

Types of pipes

Pipes made of cast iron, traditionally used in the following areas:

- Sewage systems;

- Plumbing cold water, which have a large diameter and supply houses, neighborhoods or entire neighborhoods;

- Heating mains.

In addition, cast-iron ribbed pipes are used in heating systems in warehouses and industrial premises. Next, take a closer look at the features of all their types.

Sewer

According to GOST 6942.0-69, sewage cast-iron pipes are made of gray cast iron by centrifugal casting. There are two classes of these products:

| BUT | Able to withstand a hydraulic pressure of 0.1 MPa before applying an anti-corrosion bitumen coating. |

| B | Withstand the same pressure after applying the bitumen coating. |

Pipes of class "B" are used in domestic sewer systems in buildings of typical construction. Products of class "A" are used in external systems, in places where the pipeline is exposed to heavy loads.

Note! If caulking of cast-iron pipes, which were sealed with sulfur, is necessary, it is necessary to work in a respirator, so sulfur is very toxic.

Installation of sewer systems is carried out bell-shaped way. The most difficult in this process is sealing joints.

Staking is performed as follows:

- First of all the tube is inserted into the socket.

- Then the space between the walls of the pipe and the socket is filled with tarred clay, which is hammered with its hands with the help of a hammer and a caulk. Tow must fill the space without reaching 30 cm to the edge.

- The remaining space is filled with asbestos cement mixture.

Even greater complexity is caused by the casting of cast-iron pipes with their own hands. As a rule, the asbestos-cement mixture is knocked out of the socket by a chisel, after which the junction is heated by a blowtorch.

I must say that cast-iron internal sewer systems can be found less and less, as they were replaced by plastic. This is due to the shortcomings of the "cast iron", which are given above.

Note! There are many fittings on sale that allow you to make the transition from a cast iron pipe to a plastic pipe and vice versa. Such adapters may be required in a high-rise building to replace the cast-iron part of the riser located in the apartment with a plastic one.

Plumbing and heating mains

The main task of cast iron water supply in this case is pressure resistance. Of course, strength and bonding are important. The installation of the water supply system is carried out in a bell-shaped manner, the staking is performed as described above, or by means of rubber rings.

VCHSHG pipes without sockets are applied to heating mains. Their installation is carried out by welding with special electrodes.

Tip! It is possible to repair cast iron pipes with the help of cement, which is perfectly bonded with cast iron. For example, if there is a crack in the sewer riser, you can eliminate the leakage with the help of cement mortar and bandage.

Heating systems

For use in heating systems, a special economizer ribbed cast-iron pipe is used. In fact, this is a finished oblong radiator, which has a large finning area.

Along the edges of these products have flanges or threads that allows you to connect them with other elements of the system. Such radiators can be assembled into a multi-loop register, or they can be started as a single heating element.

Other uses

In addition to the installation of sewers, water pipes and heating mains, these pipes are also used in some other areas, in particular during the installation of gas and oil pipelines. For these purposes, the use of high-pressure pipes, which are connected by a welded method, as the systems operate under high pressure.

Another area of application in which the cast iron pipes have no equal is the well. Unlike plastic analogs, they are not afraid of ground movements. The diameter of casing pipes, as a rule, is small. They are connected by welding or thread.

Conclusion

Thanks to the development of technology, cast iron pipes have become quite modern materials that are used in various industries. For a number of performance properties, they are superior to steel and plastic analogues.