Cast iron plumbing pipe according to gost 9583 75:

Cast iron pipes, as a rule, are consistently associated with sewage. Few people know that they have been massively used for laying water supply lines for more than two centuries. In this material we will study the features of cast iron water pipes, the requirements of GOST to them, applicable methods of installation and repair.

Cast iron or steel

Those who were in the basement of Peterhof, certainly drew attention to the massive pipes that supply its famous fountains with water. This is one of the oldest functioning iron pipelines before our time. It was built for centuries; at the same time, the builders of the royal residence, frankly speaking, did not particularly consider the costs.

In the second half of the last century, economic expediency came to the fore. Indeed, why build a water supply system with a half-century resource if, after 40 years, the area of the city will be expanded and rebuilt with the laying of new highways?

It was then that steel main water mains became widespread - relatively cheap and, most importantly, much more technological in terms of installation.

Tip: electric welding and external waterproofing with bitumen are performed much faster than manual embossing with the fill of the socket.

The consequences of saving are quite predictable and are still felt:

- The resource of a pipe laid in the ground, despite waterproofing measures, rarely exceeds 30-40 years. After this time, numerous fistulas in it make the loss of drinking water unacceptable.

Curiously: according to estimates of local authorities, in Sevastopol, the city where the author lives, due to the deterioration of the water supply network, 40% of water is lost.

- Not only that: the steel pipe is actively overgrown with lime deposits and rust inside. For a couple of decades, the clearance can be reduced by 3-4 times with a corresponding drop in pressure and maneuverability.

And what does cast iron look like on this dull background?

- With proper quality external waterproofing, the actual service life of the pipe laid in the ground is not less than a century.

- The pipeline practically does not overgrow from the inside.

The only problem of a cast-iron plumbing is a great sensitivity to ground movement: where the steel pipe is slightly deformed, the cast-iron will burst.

Standard

The current standard for gray cast iron water pipes was introduced in 1977; the last changes were made to the text quite recently, in 2011. So, what should be the cast-iron pipes for water supply in accordance with GOST 9583-95?

Dimensions

The standard provides cast-iron water pipes of three classes for wall thickness - LA, A and B.

| Conditional pass, mm | Wall thickness mm | ||

| LA | BUT | B | |

| 65 | 6.7 | 7.4 | 8.0 |

| 80 | 7.2 | 7.9 | 8.6 |

| 100 | 7.5 | 8.3 | 9.0 |

| 125 | 7.9 | 8.7 | 9.5 |

| 150 | 8.3 | 9.2 | 10.0 |

| 200 | 9.2 | 10.1 | 11.0 |

| 250 | 10.0 | 11.0 | 12.0 |

| 300 | 10.8 | 11.9 | 13.0 |

| 350 | 11.7 | 12.8 | 14.0 |

| 400 | 12.5 | 13.8 | 15.0 |

| 500 | 14.2 | 15.6 | 17.0 |

| 600 | 15.8 | 17.4 | 19.0 |

| 700 | 17.5 | 19.3 | 21.0 |

| 800 | 19.2 | 21.1 | 23.0 |

| 900 | 20.6 | 22.3 | 25.0 |

| 1000 | 22.5 | 24.8 | 27.0 |

The mass of the running meter of the pipe varies from 11.3 kg (65 mm, LA class) to 627 kg (1000 mm, Class B). The standard provides for the production of bell-shaped pipes of measured length (2; 3; 4; 5; 6; 7; 8; 9 and 10 meters) and non-measured length from 2 to 10.5 m.

Requirements

The transition of the cylinder in the socket can be made with a slope or in the form of a ledge.

The dimensions of cast iron pipes for water supply may differ from the nominal within the following limits:

- The length of the measuring tube is + -20.

- Wall thickness - -1 + 0.5.

- Outer diameter (up to 300 mm) - + - (4.5 + 0.0015D).

- Outer diameter (over 300 mm) - + (4.0 + 0.0015D) - (5.0 + -0.0015D).

- The inner diameter in the socket is + (2.5 + 0.002 D) - (1.5 + 0.002D).

Note: for D, when calculating the tolerances, the nominal diameter is taken.

Ovality cannot deduce a pipe for normalized deviations from the nominal size. Deviation of the real mass of a pipe from the calculated one cannot exceed five percent. Pipes are subjected to hydraulic pressure tests, which are determined by their class and nominal size.

| Do | Test pressure, kgf / cm2 | ||

| Class B | Class A | Aircraft class | |

| 300 and less | 40 | 35 | 25 |

| 300 - 600 | 35 | thirty | 20 |

| More than 600 | thirty | 25 | 20 |

Note: working pressure in water mains usually does not exceed 3-4 atmospheres. Up to 8-10 kgf / cm2 it can increase only after pumping, within the engineering system of a house or a small microdistrict.

The pipe end face opposite to the bell should be cut perpendicular to its axis with a deviation of no more than 0.5 degrees.

Inside and outside the product is covered with a protective non-toxic material. In this case, the coating should not interfere with the sealing of the butt joint, peel off and soften at temperatures up to +60 C.

Important: at the request of the customer elements of the pipeline can be supplied without coating.

Installation and repair

How to caulk plumbing plumbing pipe during installation? Are the sockets cracked and chipped?

The main stage of sealing the pipe socket is its sealing with a cabol oiled with organic fiber. The harness fits into the centered bell-joint as tightly as possible, after which it is additionally compacted by hand with the help of chasing and a hammer.

Butt little seal: the cabol must be protected from biodegradation, mechanical damage and other adversities.

How it's done?

- Conventional cement brand 400. Water-cement mixture, prepared in a ratio of 1: 9, as tightly as possible clogs the socket and is compacted by stamping until it starts to bounce off the cement plug. Then the socket is wrapped with wet rags for up to a day.

- Asbestos cement mixture, prepared in a ratio of 1: 2, followed by the addition of 10 - 12 volume percent of water. It is compacted like cement; Asbestos fibers prevent cracking.

Important: with the same success you can use fiber - chopped fiberglass.

- Expanding cement. Unlike the usual, it does not require compaction.

- Melt of sulfur with the addition of 10 - 15% ground kaolin. For obvious reasons, you can pour only a vertical or inclined socket; As a rule, the gray assembly is sealed at the factory.

- Molten lead.

- Finally, lead can be used to stamp atop cabbies.. A thin rod of soft metal tightly fills the groove, reliably protecting the organic fiber.

Important: lead and its compounds are toxic. Asbestos fiber and fiber are also not so useful for respiratory organs. Hence, the obvious instruction: when doing the relevant work with your own hands, you should not forget about personal protective equipment.

Repair of cast-iron water pipes is possible only with minor transverse or longitudinal cracks far from the socket: in this case, a pre-cast iron or steel clamp with a rubber gasket is superimposed on the pipeline section. In other cases (chipped sockets, longitudinal cracks of considerable length) the pipeline section is replaced.

Alternatives

VCHSHG

First meeting

Under this reduction lies the so-called high-strength nodular cast iron.

To explain the meaning of the term, you need to briefly delve into the wilds of physics.

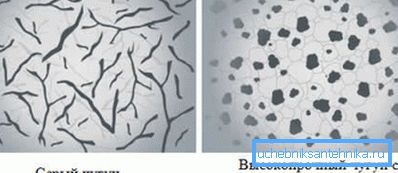

- All the main differences of cast iron from steel - brittleness, low ductility and high resistance to corrosion - are determined by the presence in it of one of the forms of carbon - graphite.

- Regular graphite has the form of miniature flat scales. However, when recrystallization occurs when some additives are introduced into the molten gray iron (in particular, magnesium and its compounds), it changes its shape to spherical.

- At the same time, the physical properties of the metal change significantly: it acquires viscosity, plasticity and resistance to shock loads, while maintaining corrosion resistance.

What is especially nice is that the price of a ton of material changes slightly during transformation. The total proportion of additives that cause recrystallization of carbon does not exceed 0.08% by weight of cast iron.

Flare pipe water pipes from the high-frequency iron group are currently the main alternative to gray cast iron.

- Compressive and flexural strength, they are superior to cast iron, not to mention all types of polymer pipes. Accordingly, the pipes of the VCHSH water pipelines can be laid under busy motorways and on unstable soils. They have all the qualities of steel, except for their Achilles heel - low resistance to corrosion.

- The problem of laborious and non-technological embossing of the sockets is completely solved. Instead of embossing used sockets with ring rubber seals. Of course, with significant pipe sizes, the assembly of sockets involves the use of heavy machinery; however, the mass of these pipes in any case will not allow to install the pipeline manually.

Note! The use of rubber seals permits a slight deformation of the socket connection (change in the relative position of the pipes) without compromising tightness.

Normative documents

The production of pressure pipelines from VChGH is regulated by a separate standard - GOST R ISO 2531-2008.

Highlight its key points.

- According to the document, pipes and fittings can have nominal sizes from 40 to 2,600 millimeters, which allows the use of chewing glands to create highways that feed entire cities.

- The composition of the metal, according to GOST, should not have a harmful effect on the composition of water.

- The length of pipes is regulated by the standard depending on their nominal diameter:

| DN, mm | Length, m |

| 40, 50 | 3.0 |

| 60 - 600 | 4.0; 5.0; 5.5; 6.0; 9.0 |

| 700, 800 | 4.0; 5.5; 6.0; 7.0; 9.0 |

| 900 - 2600 | 4.0; 5.0; 5.5; 6.0; 7.0; 8.15; 9.0 |

The maximum allowable curvature is no more than 0.125% of the pipe length.

As an external coating of the pipeline, depending on the operating conditions, can be used:

- Zinc metal.

- Zinc paint (zinc powder in a polymeric binder).

- Polyethylene.

- Polyurethane.

- Fiber cement.

- Adhesive polymer tape.

- Epoxy resin.

- Bituminous mastic or paint.

For internal protection of pipes and fittings it is permissible to use:

- Cement mortars (Portland cement, Portland slag cement and high alumina cement).

- Polyethylene

- Polyurethane.

- Epoxy resin.

- Bituminous paint (mastic).

The marking of pipeline elements should indicate:

- Manufacturer (name or trademark).

- Year of manufacture.

- Reference to material (VChGH).

- Nominal size.

- The standard by which the product is manufactured.

Polyethylene

Polyethylene pressure pipes are the main alternative to cast-iron plumbing today.

A detailed acquaintance with them is clearly beyond the scope of our material, so we will pay attention only to their key properties.

- The service life of polyethylene is estimated by manufacturers as foggy 50+ years. In practice, this material can be considered almost eternal.

- Deposits on the walls, reducing the lumen of the pipe, can not be in principle. The smooth surface of the polymer with extremely low adhesive qualities simply will not allow clogging to form.

- All connections are made by butt welding. The strength of the joint is at least 80% of the strength of a solid pipe.

The only complaint to polyethylene, which allows cast-iron pipes to remain on the market to this day, is high plasticity and, as a result, very moderate ring stiffness. Polyethylene pipeline can be laid in a deformable soil only with the protection of reinforced concrete chute.

Conclusion

We will consider our acquaintance with classical and modern solutions for laying water mains to be successful. As always, the video in this article will offer additional material. Successes!