Cast iron sewer pipes: how to choose the right material for

Cast iron has long been known as an excellent material for the manufacture of sewage pipelines. Such wastewater transportation systems are distinguished by increased reliability, durability and quality. That is why cast iron sewer pipes according to GOST 6942-98 and today are widely used in the construction of both individual homes and various administrative buildings.

Types of cast iron pipes

Pressureless

This type of material used for the construction of pipelines for various purposes is known to specialists under the designation of the chewing iron alloy: high-strength cast iron, supplemented by spherical graphite.

Magnesium is used in its production, which gives pipes additional properties:

- strength;

- plastic.

The service life of cast iron sewer pipes manufactured by this technology is very long. The appearance of cracks is practically excluded in them. The properties of such a cast iron is akin to high carbon steel.

Here are a few more advantages of the pipes;

- elasticity;

- bending strength;

- impact resistance;

- corrosion resistance;

- adaptability to existing climatic conditions.

The diameter of cast iron sewer pipes depends on the scope of their application.

Most often of this material is built:

- Sewage. Pipes of VChGG are used to construct sewer networks of large industrial enterprises and multi-storey buildings.

- Water pipes. Instructions for the design and installation of these systems also provides for the use of pressure cast-iron pipes, characterized by reliability and durability.

- Main pipelines. The most important sections of the networks transporting fluid under pressure are built from cast-iron pipes, which withstand an internal pressure exceeding 1.8 MPa.

- Drilling operations. For the casing of the well and other technical needs can be used pipes VChShG.

- Oil pipelines and gas transmission systems.

Note! The price of the considered type of parts is quite high and they are practically not used for arranging individual sewage systems with their own hands. In addition, the products are very massive and have excessive strength.

Non-pressure flare

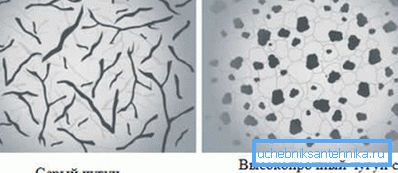

Pipes are marked with the abbreviation of the Cheka (cast iron sewer) and as the name implies, it is widely used for arranging the systems of drainage of used water. Graphite, which is included in the composition of cast iron, has not round, but spherical shape.

Pig-iron sewer pipe - 100, 150 or 50 mm - always has a bell that facilitates their installation. This structural element is an extension, which includes the smooth end of the previous section of pipe or shaped part.

The main scope of application - installation of sewer systems of small industrial facilities or residential buildings. The main thing is that the pipes do not experience increased loads during operation.

Tip! These details can be used for the arrangement of sewage in a country house. Reliability and durability guaranteed.

Their Cheka pipes can be combined systems, some parts of which are constructed of plastic. For docking used sealing rubber cuffs. A sewage cast-iron pipe of 110 mm is particularly well suited, which can be included in the existing network without the help of special adapters (GOST for PVC-pipes provides sizes of 50 and 110 mm).

In any case, the connection features allow, if necessary, to disassemble and reassemble the drain network without the use of welding equipment.

Installation Features

Cast Iron Compound

As mentioned above, the connection in most cases is carried out using sockets. It is necessary to choose the size of sewage cast-iron pipes and, if necessary, purchase additional adapters and sealing cuffs.

The entire installation process is simple and consists of several successive stages:

- The smooth end of a sewer pipe is inserted into the socket of another part.

- The gap formed between the surface of the pipe and the cut of the socket should be sealed with tow. For this, it is wound onto a part and driven into the slot with a wooden spatula and a hammer. The connection will be more reliable if you use a sealant impregnated with bitumen resin.

- In the end, it is better to use clean tow, since various impregnations will worsen the adhesion to the cement mortar.

Note! In the process of sealing the butt it is necessary to ensure that the strands do not fall into the inner space of the pipe, otherwise the formation of blockages is possible in this place.

- Then the dock is treated with mortar (cement brand M400, mixed with water in proportions of 1: 9).

- To prevent the mixture from cracking, a damp cloth should be put on top of the joint, which can be cleaned only after it has gained strength.

As an alternative, it is advisable to use a special silicone sealant or asbestos cement (a mixture of cement with asbestos fiber). In the latter case, 2 parts of cement powder is taken, 1 part of asbestos and diluted with water to the consistency of thick dough.

Docking with plastic parts

In the design and installation of sewer systems can be joined to each other parts of the system, made from both cast iron and plastic. If the pipe diameter is very different from each other, adapters are used. Otherwise, it is enough to install a rubber cuff, lubricated for tightness with silicone.

Consider the process in more detail:

- if the cast-iron pipe was used, its inner surface must be cleaned of dust and dirt, and also polished thoroughly, eliminating traces of corrosion;

- process the interior of the compound with silicone until the latter completely fills all the pores and irregularities of the cast iron;

- lubricate the rubber adapter with sealant and install it in a cast iron pipe;

- The smooth end of a PVC sewer pipe is installed in the rubber part.

Dismantling the cast iron pipeline

Most often there is a need to dismantle the sewage from cast iron in order to replace it with a new one made of plastic. This is a very time consuming process. Relieve it will help the usual "Bulgarian".

It is best to remove the pipes to the socket, which will serve in the future to connect the networks with each other. Otherwise, you will have to separately purchase additional parts to help achieve tightness.

Do not use hammers when dismantling. Cast iron is very fragile: a breakaway piece can fall into the pipe and cause blockage in the future. It is better to cut a small area, after which, most likely, the cast iron will crack without much effort.

Repair of cast iron pipes

During operation of the sewer system, chipped and cracked pipes may appear on the cast-iron pipes. The damaged area can be sealed with a rubber patch fixed with a hose clamp.

Cracks are sealed with a special mixture: 1.5 parts of copper oxide and 1 part of phosphoric acid are mixed and immediately filled with a previously cleaned and degreased area. The composition hardens very quickly and keeps quite well.

Conclusion

Cast iron is a very high quality and reliable material for the installation of sewer systems. However, parts of it have a lot of weight, and therefore during their installation and connection it may be necessary to use engineering equipment.

You can learn more about this question from the video in this article.