Chimney pipes - types, characteristics and features

The chimney is one of the most important elements of a stove, fireplace and other devices where fuel is used. Its purpose is to create normal thrust and discharge of combustion products outside the premises. From the effectiveness of the element depends on the comfortable use of heating equipment.

Thanks to the improvement of technology, the industry is ready to offer consumers new heating systems, but they cannot replace the comfort and warmth of a living flame. In this article we will tell about the types of chimneys, about their features, the rules of installation and maintenance.

What are the types of chimney

If you look around, it can be noted that most often they are made of brick, stainless steel or ceramics, although other materials can be used. In addition, they are often combined with each other, for example, they enclose a steel chimney with a brick.

Brick

It was he who has long been considered a traditional material not only for the manufacture of stoves and fireplaces, but also for the construction of pipes that exhaust gases from their fireboxes.

Tip: if you add a lime mortar to the clay, you can increase its resistance to high temperature.

Consider the disadvantages of bricks:

- absorbs moisture, so often have to do to repair the structure;

- the mass of material requires the preparation of a reinforced foundation structure;

- high installation costs.

Therefore, it is rarely used today as a base material, mainly as an addition to others, in particular to metal. Thanks to their combination increases the reliability of the design and improves its appearance.

Steel

Such products withstand high temperatures and have good strength. Their main advantage - the pipe for the chimney is set up quickly and does not require large funds. In fact, you can refuse to use the labor of employees.

But, the use of steel products in its pure form is associated with some disadvantages:

- due to temperature and precipitation they rust;

- possible burnout of the pipe with prolonged use;

- after a break in the operation of the furnace, frost begins to form inside them, then turning into moisture, which flows into the furnace.

Do not save from such trouble and galvanized products for the chimney. Because of the thin walls, they can adversely affect the normal level of thrust and turn into a fire hazard.

Sandwich chimney

Manufacturers took into account these problems and proposed a new type of products for removal of fumes from stoves and fireplaces - a sandwich chimney in which a layer of basalt is installed between the layers of stainless steel. It is able to retain heat perfectly, keeping the normal temperature inside the pipe.

Its price is higher than the steel one, but the efficiency is corresponding.

Their advantages:

- relatively small weight, when compared with brick options;

- they can be used to create aesthetic and sophisticated details for circumventing obstacles and fastening;

- high fire protection;

- rust resistance;

- prostate and ease of installation;

- resistance to atmospheric "whims" - low temperature, precipitation and high humidity;

- resistance to high temperature combustion products.

Asbestos cement

Experts doubt the ability of asbestos-cement chimneys to ensure the normal functioning of the stove or fireplace.

Of course, such products have certain positive qualities, including:

- reliability;

- resistance to atmospheric conditions;

- high fire safety.

However, at present, chimneys of this material are not made, due to the fact that after some time, the products begin to gradually collapse from the inside. This is facilitated by low temperature drops outside and high inside.

Also, their strength is not the same as that of metal products; therefore, heated gases contribute to the release of asbestos, which adversely affects human health.

From the above, we can conclude that the most acceptable option for today is a sandwich chimney. Thanks to him, he manages to efficiently use modern heating devices, which has made this design so popular.

Chimney construction

The most acceptable option is considered - a circular cross section, which contributes to a better passage of combustion products. In rectangular and square, turbulences often occur, contributing to the formation of soot plaque, reducing thrust force. Steel pipes in combination with the newest manufacturers' developments create optimal conditions for the removal of residual products of combustion of fuel.

Special features

Chimneys differ in purpose and are:

| Mounted |

|

| Indigenous | Apply to work with two heating devices housing. For example, when a fireplace and a stove are brought to one exhaust device. |

| Wall | Use for work with several furnaces which are located on different floors in one house. |

Below is the instruction that is used to select and install the device:

- comply with the rules that apply to the installation site of the equipment;

- be waterproof, sealed, i.e. not to pass the combustion products, have appropriate insulation, the material should not rust and be resistant to the pressure of gases;

- Installation is strictly according to the regulations, i.e. the connection is made to so many devices for which the chimney is designed;

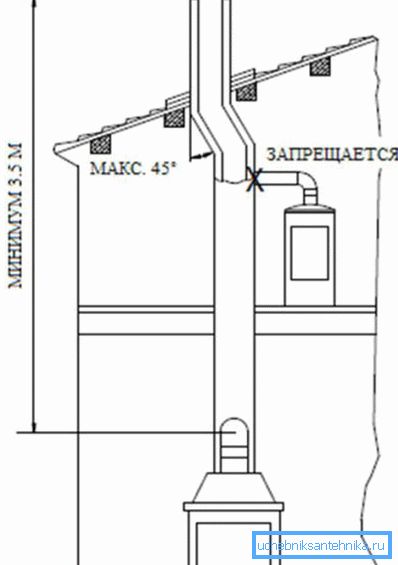

- the internal diameter of the chimney pipe must be equal to the diameter of the pipe coming out of the furnace, or larger, the minimum height is 3.5 m;

- be located in a vertical position, the deviation from the axis is allowed at an angle of up to 45 °;

- be located at a sufficient distance from flammable and combustible materials, have an air gap or suitable insulating material;

- the internal section should be uniform, preferably round. Rectangular or square should have rounded corners with a radius of 20 mm, with a maximum aspect ratio of 1.5;

- walls should be smooth, with no ledges, if possible. Bends - correct and without break.

Tip: do not make mobile or fixed holes on the chimney, which are used to connect appliances, except those to which it is connected. It is prohibited to conduct service pipes or other air ducts inside the device, regardless of their size.

Conclusion

The removal of exhaust gases from the stove or fireplace is a very important stage, on which depends not only the operation of the device, but also the health of people. This issue should be approached with extreme caution, and it is better to invite specialists (see also the article Pipe D16t: standard and features of the material).

You can install chimneys from different materials, but at the moment the “sandwich” type pipe is considered optimal.

The video in this article will help you find additional information on this topic.