Chimney: purpose, types and design features

Chimneys are just needed in homes that use heating with open fire. It should be borne in mind that such products will be operated in a fairly aggressive environment, which means that the choice of material for manufacturing must be approached very carefully. However, it is immediately important to mention that the chimney is not used as a single element, and it is a whole system that requires careful development.

Metallic materials

To begin with, it must be said that there are many modern materials for the manufacture of such systems. However, first of all, it is worth considering the simplest options for creating these structures. At the same time, the height and diameter of the furnace tubes will not be affected, since this depends only on the previously developed project and the adopted standards.

Galvanized

This type of material is considered one of the most common.

This is due to the fact that the cost of such products is just perfect with its quality.

- Such chimney pipes are very easy to install and have a relatively small weight.. It also greatly facilitates all work, eliminating complicated and expensive fasteners. Given this, the entire installation can be done by hand, without having special equipment or qualifications.

- It is important to mention that products made from this material need additional protection when passing through the ceiling, attic and roof.. The fact is that during operation such a structure is very hot and transfers heat very well.

Tip! The entire galvanized system should be purchased from one manufacturer. So you can solve the problems associated with the docking and pre-assemble the structure on the spot.

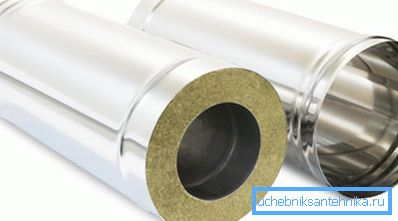

Stainless steel

Installing stainless steel chimneys is quite difficult.

The fact is that this material needs special welding, and the connecting elements of another type did not manifest themselves properly.

- It is worth noting that the cost of this design is quite high.. It depends not only on the price of the material itself, but also on the installation work.

- It is also necessary to mention that the life of such systems is slightly higher than galvanized products.. The fact is that stainless steel does not always tolerate intense heating or rapid cooling, and special steel, which experts recommend using is worth a lot of money.

Tip! Professionals usually do not use this material for the construction of such structures. It does not justify itself in operation, and when comparing its cost with modern systems, it can be concluded that the costs are the same.

Black metal

This type of material is used for such works for a long time.

It is much easier to take a plumbing pipe of the desired diameter than to look for expensive systems, which at the same time have approximately the same service life.

- All ferrous metal chimneys outside are usually painted with special heat-resistant compounds.. This will protect the product from corrosion and will not allow the coating to evaporate or lose its properties when heated.

- Usually, experts try to use solid pipes for such work, but if this is not possible, then special adapters can be used..

Tip! It is not necessary to use old or heavily rusty pipes for such works. They will quickly become unusable and may even cause a fire.

Modern materials

Today, the furnace metal pipe is used very rarely. Professional masters are trying to apply for the construction of new building materials that have a long service life and excellent quality.

Ceramics

This material is very popular in our time. Such pipes can be considered practically eternal, since they do not fade, are resistant to corrosion and retain heat well.

However, it must be said that the installation instructions also recommend the use of special insulators to isolate such a pipe from products that may be exposed to fire as a result of intense heating. At the same time, specialists usually use whole blocks for such purposes, which are built into the ceiling and provide not only protection, but also create an aesthetically beautiful place of transition.

Tip! There are many types of ceramic pipes that have different types of connecting elements. Therefore, when choosing them at the moment you need to pay special attention.

Blocks

One of the latest innovations in this area was the emergence of special blocks of lightweight concrete, in which parts of ceramic pipes were already bricked up with insulation. It is important to mention that the price of such a product is relatively low, and the quality of its performance is at the highest level.

Pipes made of such material not only have a long service life, but also have a good appearance. However, it must be remembered that for their installation it is necessary to use special refractory mixtures that are used to fix the elements with each other.

Tip! When purchasing such products, you need to carefully examine their design and check the ceramics for damage. It is also worth checking the compatibility of all elements by matching in place.

Conclusion

Having studied in detail the video in this article, you can get additional data on similar constructions. In this case, it is immediately worth noting the diversity of materials for their manufacture and the complexity or ease of installation.

Also based on the text above, it is worth concluding that a galvanized chimney has long been not the most optimal solution for creating such structures. In its place come new materials that have already proven their quality and excellence.