Chrysotile cement tubes: properties and applications

To use chrysotile cement pipes in any project according to GOST 31416-2009 is very beneficial, both technically and economically - they are quite durable (the service life is about 25-50 years) and, besides, 2-3 times cheaper steel, iron and polymers. Such bright positive qualities are ensured both by the technological characteristics of the chrysolite cement itself and by the design features of all elements of the laid pipeline. Below we take a closer look at this, and in addition, we will demonstrate on the topic of the video in this article.

General information

Application area

- The current GOST 31416-2009 establishes and defines the general requirements for pressure and non-pressure pipes and couplings of dryzoltsement. Free-flow materials are used for sewage systems, for collectors of various drainage systems of land reclamation, for ventilation channels (exhaust ventilation systems), drainage in heating networks, as well as for laying cables and garbage disposal lines.

- Chrysotile cement pipes and couplings, which are designed for high pressure (with thick walls), are used to supply cities, towns and industrial enterprises and agricultural complexes with hot water at a temperature of not more than 115? C, where the working pressure is not more than 1.6 MPa. They are also used for drainage and exhaust pipe systems, associated drainage, refuse chutes and so on.

Technical features

- Does not require waterproofing, as it is absolutely not subject to corrosion;

- It is not a conductive material;

- It does not require strong thermal insulation - thermal conductivity of chrysolite cement is only 0.8 kcal / (m * h * hail) - the instruction indicates that it is 60 times less than that of steel;

- When transporting cold water on the walls there is no condensation;

- The coefficient of temperature lengthening is 12 times lower here than steel, therefore, there is no need to install expensive temperature lengthening compensators - this factor gives excellent recommendations for channelless laying. It turns out that in this case, the price falls both on the material itself and on its installation due to the design features of the pipeline;

- When forming pipes, small errors in size are possible, some deformation (increase) also occurs during the transportation of hot water, but this is compensated for in the coupling joints by rubber rings for sealing the joints;

- Water resistant. In contact with water, the material only gains strength - hardening occurs due to the physicomechanical properties of chrysolite cement;

- When transporting water inside the microorganisms do not develop, that is, the pipes do not overgrow. Therefore, additional hydraulic resistance does not occur;

- They are resistant to aggressive alkaline and weakly acidic environments;

- The use of chrysotile cement pipes at various sites entails a reduction in construction time on the order of 35-40%, reduces the need for construction equipment by 50-55% and significantly reduces the labor costs of manpower.

Note. Chrysolite cement free-flow pipes in the documentation are labeled with the abbreviation BNT, and couplings for them - BNM or polyethylene MPT. For pressure pipes, the abbreviation is BT or TT, and for couplings - CAM or TM.

| The passage is conditional | Diameter internal (mm) | Outer diameter of the winding ends (mm) | Wall thickness of the winding end (mm) | Length (mm) | ||||||

| BT-6 | W-9 | BT-12 | BT-15 | BT-6 | W-9 | BT-12 | BT-15 | |||

| 100 | 104 | 100 | - | - | 122 | 9 | eleven | - | - | 3950 |

| 150 | 146 | 141 | - | - | 168 | 11.0 | 13.5 | - | - | 1950 |

| 200 | 200 | 196 | 1888 | 180 | 224 | 12 | 14 | 18 | 22 | 5000 |

| 250 | - | 242 | 234 | - | 247 | - | sixteen | 20 | - | 5000 |

| 300 | 292 | 286 | 276 | 267 | 324 | sixteen | nineteen | 24 | 28.5 | 5000 |

| 400 | 385 | 377 | 363 | 352 | 427 | 21 | 25 | 32 | 37.5 | 5000 |

| 500 | 476 | 466 | 450 | 436 | 528 | 26 | 31 | 39 | 46 | 5000 |

Table of technical characteristics of VT (GOST 31416-2009 according to OKP 578600)

| The passage is conditional | Diameter Outside (mm) | Diameter Int. (mm) | Wall thickness (mm) | Length (mm) |

| 100 | 118 | 100 | 9 | 3950 |

| 150 | 161 | 141 | ten | 1950, 5000 |

| 200 | 213 | 191 | eleven | 5000 |

| 250 | 266 | 238 | 14 | 5000 |

| 300 | 309 | 279 | 14/15 | 5000 |

| 400 | 407 | 373 | 17 | 5000 |

| 500 | 514 | 466 | 24 | 5000 |

Table of technical characteristics of BNT (GOST 31416-2009 according to OKP 578600)

Piling

Installation work with your own hands or at work, whether it's heating, a melioration channel, cable management, sewage, and so on, are performed almost along the same lines. This is digging a trench, transporting pipes with couplings to the site, a preliminary inspection for integrity, placing all elements in a trench, another inspection, a permeability test and / or tightness (depending on the purpose) and backfilling of the trench.

The pipes are not laid directly on the bottom of the trench - a pad of sifted soil or sand is pre-loaded there, with a minimum height of 50-60 mm, which allows you to evenly distribute the load over the entire area.

In any case, the laying will be carried out under a slope, which, in turn, depends on the diameter of the pipeline (over 200 mm - 3-4 mm per linear meter), if there is no natural slope on the ground, then it is set in the process of digging a trench. Such a slope is necessary not only for free-flow sewage, but also for dry runs - after all, there will definitely be moisture that can flow in one direction.

Note. During transportation and installation of all asbestos-cement - chrysotile cement pressure pipes must be shifted smoothly, without sharp shocks and shocks, regardless of how the laying is done - with a crane or manually.

Ways to connect BNT

When mounting chrysotile cement free-flow pipeline in dry soil, use polyethylene MPT couplings, which have an internal partition for joining ends. For the MPT compound, it should be kept in hot water, preferably up to 100? C, so that it slightly increases and becomes plastic (it is also heated with a blowtorch).

The heated coupling is put on the pipe so that it rests against the end with a partition, and then the end of the other pipe is inserted there until it stops - after the plastic cools, the connection can be considered ready.

When mounting in all other soils, chrysotile-cement non-pressure couplings (BNM) are used. Their installation can be carried out without bonding materials, if the purpose of BNM is only to maintain a flat line, but in all other circumstances different bitumens, mastics or cement-sand mortar are used for adhesion.

Bitumen is considered to be the most reliable for the bundle - it is poured into the sleeve in a hot (molten) state in the holes made on the same line.

Before docking at the edges of BNT, they make a marking of the position of the BNM - this is how it will be located after the completion of the installation work, then put the clutch along these marks, and in order to center it - put wood chips around the perimeter. It is necessary to leave a mounting gap between 3 mm and 5 mm between the pipes, where the adhesive will later penetrate - this will also serve as a sealant and a buffer.

In order to seal the gap, in addition to the binder solution, a strand is pushed into the slit - hemp, rags or tow, departing from the edge about 1/3 the distance from the cuff length at this end. After that, molten bitumen begins to be poured into one drilled hole and they do this until it starts to flow from another hole - this will mean that the cavity is filled to capacity.

After pouring, the joint should remain stationary to harden bitumen, and the temperature should be natural, and the edges of the joint should be sealed, for example, by wrapping a wide (50-70 mm) resin tape.

In cases where a cement-sand mortar is used as a binder, the holes in the coupling are not drilled - it is simply put on over the mixture laid around the perimeter. The edges in this case, too, close up with a solution.

W mounting methods

Depending on the working pressure, the pressure pipes are classified into two groups: a) for water pipes, which include marks VT6, VT9, VT12, VT15; b) for heat pipelines: TT3, TT6, TT9, TT12, TT16.

| Classiness | Class (symbol) | Operating pressure P | ||

| Trumpet | Clutch | MPa | kgf / cm2 | |

| one | TT3 | TM3 | 0.3 | 3 |

| 2 | VT6 | CAM6 | 0.6 | 6 |

| TT6 | TM6 | |||

| 3 | BT9 | CAM9 | 0.9 | 9 |

| TT9 | TM9 | |||

| five | VT12 | SAM12 | 1.2 | 12 |

| TT12 | Tm12 | |||

| 6 | BT15 | CAM15 | 1.5 | 15 |

| 7 | TT16 | TM16 | 1.6 | sixteen |

Classification table

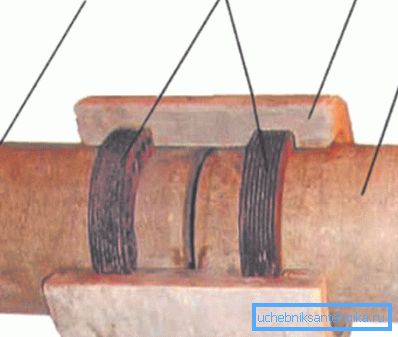

For the installation of high-pressure pipelines from chrysotile cement for joining, couplings of similar material are used, which are activated according to the principle of self-consolidation. So, for a working pressure of 6 kgf / cm2, 9 kgf / cm2, 12 kgf / cm2 and 15 kgf / cm2 Couplings for two or four grooves for sealing rings are used. But for a heat pipe with a working pressure of 16kgs / cm2 produce special, longer couplings, in which the two grooves are somewhat wider than usual.

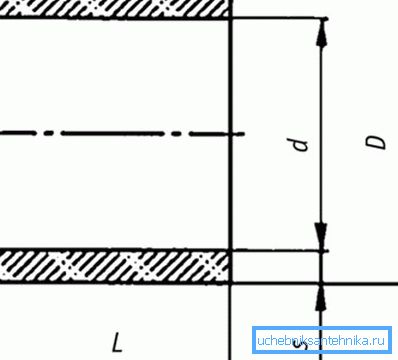

The fragmentary figure at the top shows the coupling connection of high-pressure pipes of chrysotile cement. Rubber rings for sealing the joint are supplied by the manufacturer complete with a coupling, regardless of who manufactures them - the plant itself or a third-party enterprise.

Installation of high-pressure pipelines can be carried out in two ways - under the ground and over the ground - channel and channel-less laying, respectively, and the second option is carried out at the expense of supports of a certain height. The most popular can be called an underground installation - firstly, this is the best aesthetic solution, and, secondly, it is the use in full of all the positive technical characteristics of the material.

In the case of ductless installation, there are significant limitations, for example, you can not carry out laying over roads, tram lines, railway tracks, residential sector and so on.

The outer gasket takes up a lot of usable space, but in some cases it is simply impossible to refuse it for technical reasons and they are mounted on special supports, the so-called lodgments, which stand on both sides, and the steel tape is fastened between them.

Most often such laying is carried out on the territory of industrial enterprises, outside the city and, in extreme cases, along the houses, between the pavement and the roadway.

In the case of a cistern, underground installation, high-pressure pipes of chrysotile cement are stacked exactly as they are without pressure - on a pad of sifted soil or sand. But in those situations when the steel pipeline is being dismantled and replaced with chrysotile cement, then there often remain trays that can be reused.

Note. Sometimes you can hear the question, what is the difference between chrysotile cement and asbestos-cement pipes? Interested people can be reassured - there is no difference here, it is one and the same material.

Conclusion

After reading this article and watching the video clip, you certainly understood what chrysotile cement pipes are and for what purposes they are used. In the household, they are usually used for pouring columnar (pile) foundations as a casing, as well as for posts, for example, for a fence or a grape arch.