Cold-deformed pipes: standards and production technology

How and from what blanks is cold-formed seamless pipe produced? What is it for and how does it differ from electric-welded pipes in terms of performance? What regulatory documents does production follow?

Let's try to find the answers together.

Features and scope

To begin, find out why seamless pipes are generally needed (see also the article Transparent Pipe: materials and characteristics).

Alas, it is quite problematic to think of using them when installing their own hands plumbing or any other household equipment. The price of products is too high, and the strength is deliberately redundant for any reasonable purpose.

In short, they are in demand where extreme strength is needed (above all - to break). An alternative technology, much cheaper and more technological - the production of welded pipes - has a significant drawback.

Despite all the methods of control, the seam will always be a weak point: if the strength limit is exceeded, the pipeline will break along its line.

To clarify: all electric-welded pipes should not be thrown into a common pile. The quality and strength of the seam vary greatly depending on the chosen technology; Thus, high-frequency welding gives a worse weld quality compared to electrode welding in an argon environment.

We give some examples of applications for seamless pipes.

- Pump and pipeline pipelines used for pumping oil and gas condensate under high pressure.

- Casing oil wells.

- Pipelines to maintain intra-layer pressure in the development of underground deposits.

- The walls of compressed gas cylinders.

- Hydraulic cylinders.

By combining steel grade and wall thickness, you can get pipes with characteristics that satisfy virtually any strength requirement.

Production technology

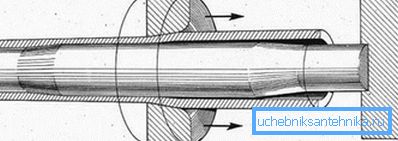

The blanks for production are the so-called conversion pipes, which are produced by hot deformation from cylindrical billets - rods. The rod is aged in a furnace to a temperature at which the steel becomes plastic, and turns into a hollow cylinder - the sleeve - on the so-called piercing mill.

Simply put, its further processing is reduced to rolling on a group of successive rollers with a gradually decreasing size on a stationary or rotating mandrel. The key difference from hot-rolled pipes is that, in contrast to them, cold-formed pipes undergo basic operations at a temperature below the recrystallization mark.

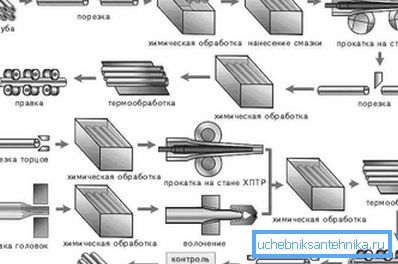

What are the main stages of production?

- Cutting blanks into pieces of measured length.

- Chemical treatment required to remove rust and scale from the surface. For carbon steels, solutions of acids (sulfuric and hydrochloric) are used, for alloyed ones - a caustic soda melt with an oxidizing agent NaNO3. After etching, the workpieces are successively washed with hot water in a bath, then with a stream of cold water under pressure, and then dried for 30-30 minutes at a temperature of 150 - 180С.

- The blanks are sent to the baths with lubricant and technological coatings, which reduce friction losses during further processing.

- Then the conversion pipes get to the HPT mill (cold rolling of pipes), where the thickness of their walls decreases during the rolling process. Sizing rolls at the same time slightly increase the length of the workpiece.

- Further processing includes straightening, trimming the ends, calibration in reducing rollers or drawing in a ring calibrator. The pipe is finally formed, turning into a product with an ideal geometry and a given diameter.

- The last stage before passing the quality control - heat treatment. When tempering (heated to a temperature of 50 degrees above the point of recrystallization), followed by a gradual cooling, the accumulated internal stresses of the material are removed, its plasticity and viscosity increase.

Regulations

Scroll

Here is a list of standards according to which cold-formed seamless pipes are produced:

| Document | Content |

| GOST 8734-75 | Product Range |

| GOST 8733-74 | Technical requirements for production |

Curiously, on the sites of many dealers of products of pipe-rolling enterprises there are outright disinformation. Non-existent or irrelevant standards are mentioned in the lists of rationing documents.

Let's give some examples.

- GOST 8733-87 for steel seamless pipes - an updated version of the standard number 8733-74. Shortly after the adoption of the document was canceled and is currently not used.

- GOST 8734-78 for steel seamless pipes never existed. Its number is a mixture of 8732-78, containing a assortment of hot deformation pipes, and the above-mentioned 8734-75.

- Similarly, seamless steel pipes according to GOST 8733-75 are an obvious mixture of product conformity to the standards 8733-74 (technical conditions) and 8734-75 (gauge).

- Seamless steel pipes according to GOST 8732-75 also do not exist in nature. And this number is a clear distortion - 8732-78, containing a range of hot-rolled products.

- Finally, the seamless steel pipes according to GOST 8734-87, mentioned on the site of a certain dealer, are a most amusing fake.

A standard with such a number actually exists, only it has nothing to do with GOST. This number belongs to the document in the International Organization for Standardization (ISO), which. corresponds to the Russian GOST 24296-93 cylindrical hardened pins.

GOST 8734-75

We now turn to the study of the main points of the standards. So, what should be a seamless cold-deformed pipe according to GOST 8734-75?

The document identifies four classes of products.

| Class | The ratio of outer diameter to wall thickness | Absolute values of diameter (D) and wall thickness (S), mm |

| Very thin walled | 40 or more | D less than 20, S less than 0.5 |

| Thin-walled | 12.5 - 40 | D less than 20, S less than 1.5 |

| Thick wall | 6 - 12.5 | |

| Thin-walled | Less than 6 |

Pipes are supplied:

- Unmeasured length (from 1.5 to 11.5 m).

- Dimensional length (4.5 - 9 m with a tolerance of +10 mm).

However: for foreign trade organizations delivery of products of measured length from 4 meters is provided.

- Length, multiple dimensional (from 1.5 to 9 m with an allowance for each cut of 5 mm).

The full list of diameters and wall thicknesses, which GOST 8734-75 provides for seamless steel pipes, is too large for a small article, so we only give boundary values.

- The diameter is from 5 to 250 mm.

- Wall thickness - 0.3 - 24 mm.

By the way: in agreement with the customer, the assortment can be expanded. In particular, it is possible to produce pipes with an outer diameter of 4 and a wall thickness of 0.2 mm.

Products are delivered exactly according to the given values - outer diameter and wall thickness. If desired, the customer can be delivered on the internal diameter and wall, or both diameters and varioured.

The range of tolerances is predictably determined by key parameters.

| Diameter tolerance | Diameter, mm |

| 0.15 mm | 4 - 10 |

| 0.3 mm | 10 - 30 |

| 0.4 mm | 30 - 50 |

| 0.8% | 50 or more |

| Wall thickness tolerance | Wall thickness mm |

| 0.12 mm | Up to 1 |

| ten % | 15 |

| 12 % | 1 - 2.5 with a diameter of 100 mm |

| eight % | Over 5 |

GOST 8733-74

As already mentioned, GOST 8733-74 for seamless steel pipes contains technical conditions for their production.

Which ones?

The document provides for the following groups on the method of regulation:

- B - with standardization of chemical composition.

- B - with standardization of chemical composition and mechanical properties.

- D - with standardization of chemical composition and mechanical properties with the control of the latter on the heat-treated samples.

- D - with the standardization of hydraulic tests.

- E - with the regulation of heat treatment, steel grade and mechanical properties.

In the general case, the products are delivered to the customer after heat treatment (firing, tempering or normalization). The exception is a particularly thin-walled pipe with a ratio of the diameter to the wall thickness D / S = 50 or more; however, here everything is determined by the contract between the customer and the manufacturer.

The presence of cracks, films, sunsets and cavities on the surface is not allowed. Minor defects such as dents and traces of detached scale are permissible, but should not take the product beyond the limits of the tolerances set by the standard.

In general, the ends are cut at a right angle to the longitudinal axis. On pipes for welding, a chamfer can be cut at an angle of 34 - 40 degrees to its end; at the same time, a ring with a width of 1 to 3 millimeters is left on the edge.

The consumer may require hydraulic pressure tests, which is calculated by the formulas of GOST 3845, but not more than 200 atmospheres. Tests with high pressure are possible in consultation with the manufacturer.

However: instead of hydraulic testing, non-destructive testing is possible, the instructions for which are contained in the same standard under the number 3845.

In addition, for heat-treated pipes made of steel grades 20, 10 and 15 XM upon the customer's request, the following types of tests are provided:

- On a bend - for all standard sizes.

- For distribution - for diameter up to 160 and wall thickness up to 8 mm.

- Flattening - with a diameter of 22 and a wall thickness of up to 10 mm.

- On boring - for diameters D = 25 - 160 mm with a wall thickness:

- With D up to 60 mm - up to 10% D.

- With D = 60 - 108 mm - up to 8% D.

- With D = 108 - 140 mm - up to 6% D.

- With D = 140 - 160 mm - up to 5% D.

Products are accepted in batches.

Batch size is limited by their size:

- With a diameter up to 76 mm and a wall thickness up to 2.5 mm - no more than 400 pieces.

- With other sizes - no more than 200 pieces.

At the request of the consumer, the batch may consist of pipes made from steel of the same heat.

Conclusion

We hope that they did not tire the reader with an abundance of numbers and dry technical information. Alas, the very subject of the article implies a very moderate amount of lyrical digressions (see also the article Shell for pipes: we study the features and technology of installation).

As always, the attached video will offer additional materials. Successes!