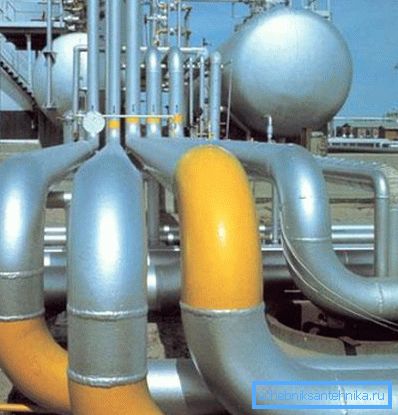

Coloring of pipelines: differences, purpose, standards

Modern engineering, industrial, urban and other communications, their networks and systems are designed to transport various substances that are dangerous to humans and the environment. Therefore, even in the Soviet times, a special document GOST 14202 69 was developed on the color of pipelines, which strictly regulates what color markings and other signs should notify personnel about the contents of the pipe with which to work.

Communication security

Purpose

It should be noted right away that this requirement is by no means a recommendation, moreover, non-compliance or non-compliance with the requirements for SNiP is properly strictly punishable by law.

This is not because someone wanted to paint this world with new fresh paints, but because in case of an accident, maintenance, as well as other contacts and manipulations with the listed objects, rescue services, EMERCOM and other special services should know for sure what substances they have to deal with and what measures should be used to contain and eliminate the danger.

It should also be recalled that pipelines carry far from only tap water, heating substrates and sewage.

Modern production and the chemical industry has long been manipulated with substances such as:

- Combustible and explosive gases of different origin;

- Flammable and explosive liquids of different origin;

- Toxic gases and liquids;

- Superheated steam;

- Saturated steam;

- High pressure substances;

- Non-combustible gases and liquids;

- Acids, including smoky and concentrated;

- Alkalis of different composition;

- Hazardous organic compounds;

- Air vacuum;

- Any substances under high pressure;

- Other dangerous or especially important substances.

Note! In addition to the immediate danger dictated by the chemical composition of the substance being transported, temperature (both high and low), as well as pressure and volume play an important role.

It goes without saying that an emergency situation arises in case of a main line accident and leakage, fire or other dangerous activity of the transported substance, and emergency services, rescue services, evacuation crews and other emergency response participants must be fully informed about the nature and composition of the source of danger.

The consequences of a catastrophe can cover not only local, local, district, regional, and even national and global scales. This circumstance takes the topic under discussion to a completely different level, and here the issues are not decided by the family council - whether to put the paint cheaper with their own hands or to call a painter.

This is a national problem, which is one of the most controlled and accountable at the level of ministries and departments of different countries and their unions.

Note! The price of non-compliance, ignoring, sabotaging or improper fulfillment of labeling requirements is the life of many people, the integrity of the infrastructure, the efficiency of industry and life support enterprises of cities, hospitals, other important objects, is a matter of preserving and protecting natural objects, including unique ones.

Groups of substances and corresponding colors

According to GOST 14202 69, it was decided to divide all transported substances into ten enlarged groups, which are united by one or another common qualities.

Thus, all substances in the first approximation are divided into the following groups:

- Water (technical, drinking, waste);

- Water vapor;

- Air;

- Combustible gases, including liquefied;

- Non-combustible gases, including liquefied;

- Various acids, including fuming;

- Alkalis;

- Flammable liquids;

- Non-flammable liquids;

- Other substances.

Certain colors correspond to these enlarged groups of substances, which indicate the presence in the vessel of one or another chemical substance:

| Group number | Transported substance | Color Name |

| one | Water | green  |

| 2 | Steam | red  |

| 3 | Air | blue  |

| 4.5 | Combustible and non-combustible gases | yellow  |

| 6 | Acids | Orange  |

| 7 | Alkalis | Violet  |

| 8.9 | Combustible and non-flammable liquids | brown  |

| 0 | Other substances | Gray  |

Note! In addition to the listed colors and objects, fire-fighting systems and installations must be painted in signal red color regardless of their content.

Paint Coating Methods

The identification color is applied in a continuous layer over the entire surface or in separate sections.

The method of applying paint is chosen based on a number of considerations:

- Property location;

- Pipe diameter;

- Trunk length;

- The number of jointly located lines;

- Requirements of the rules of industrial safety and life safety in the industry;

- Industrial hygiene requirements;

- The conditions of visibility and transparency of the air environment at the facility;

- The lighting conditions of the object itself;

- The convenience of staff;

- General architectural solution or ensemble of the area.

If the concentration of bright colors for one reason or another is unacceptable, as well as in workshops with a large number and length of communications - the marking is done in sections.

If the number of communications is small and their length is small, moreover, if it does not worsen the working conditions in the workshops, the coloring is continuous.

Outdoor objects are covered with a continuous layer only taking into account the impact on the coating of solar radiation and other weather factors.

If the coating is applied inside workshops and production areas, then in this case, the rest of the pipe surface is usually painted in the color of the walls of the room. At the same time, using other marking shades to fill the gaps is strictly prohibited.

Note! In the case of laying of highways in non-passage channels or in channel-free way, marking is applied in the areas of inspection chambers and wells.

Another important rule is that identification plots are applied according to local features (weather, climate, solar activity, visibility). At the same time they are located in the most important and important places - connections, branches, at the sites of selection and instrumentation, at the points of passage of the main routes through walls and other obstacles, floors, partitions, as well as at the inputs and outputs of production facilities.

Note! The frequency of application inside objects and on the territory of outdoor installations is at least 10 meters, on open trunk lines and pipelines - from 30 to 60 meters, depending on the terrain conditions.

The width of the sections directly depend on the diameter of the pipeline. For objects with a diameter up to 300 mm - not less than 1200 mm (four diameters), for objects with a diameter exceeding 300 mm - not less than 600 mm (two diameters).

If the dimensions of the highways are really large - is it possible to apply the floor at least? pipe circumference with regard to insulation.

Note! The listed application rules and dimensions must necessarily correspond to the diameters of trunk pipes and pipelines.

Dangerous objects

Here GOST leaves only three primary colors:

- red - explosive and flammable, flammable;

- green - neutral;

- yellow - toxicity, toxicity, deep vacuum, asphyxiation, radioactivity, the ability to cause chemical burns or just dangerously high pressure.

For pipes containing substances with multiple hazard factors, multiple rings can be applied, that is, it can be a red and a yellow ring at the same time.

Note! Pipelines with a deep vacuum, except for coloring pipes and rings, must be labeled "Vacuum".

In addition, the short chemical name of the substance is written on the rings themselves and indicate the direction of its movement. In situations of normal and emergency events, this is extremely important and affects a variety of factors that may affect people's lives.

For especially dangerous objects, among other things, warning signs of various contents are used, the color, form and content of which are also strictly regulated and installed. The plate must have a triangular shape, a yellow background and black graphics.

Such signs or signs usually denote the following substances:

- Strong poisons;

- Explosive compounds;

- Radioactive substances;

- Other particularly dangerous compounds and their mixtures, especially harmful when spraying.

If the indication does not contain specifics, then an exclamation mark is simply left on the yellow background.

Also use marking plates that do not change color when a substance leaks. They usually contain an indication of the type of substance and indicate the direction of movement of the medium by one of the sharp ends, sometimes using double-edged shields.

Conclusion

To ensure the normal operation and liquidation of accidents of modern industrial and trunk facilities, the transfer of substances through pipelines is necessary. For safety, they are marked according to GOST and SNiP, which is clearly shown in the video in this article.