Compression fittings for copper pipes: products made of

How are the crimp fittings for copper pipes? What about devices with similar functionality for steel (plain and corrugated stainless), metal-plastic and polyethylene? Does this class of fittings have any specific problems? Let's try to figure it out.

Copper

How the copper pipes are connected by crimp fittings depends on the type of these fittings.

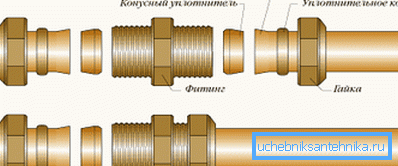

Soft seal

In this case, tightness is ensured by the expansion of the rubber or silicone ring seal, which is clamped between the fitting body and the spacer ring when the nut is tightened. The method of assembling the compound is, in general, fairly obvious.

On the tube of the corresponding diameter are alternately worn:

- Cap nut.

- Retaining ring.

- Compactor.

Then the tube is inserted into the body of the fitting, after which the union nut is tightened - first by hand, then 1-2 turns using a pair of adjustable or open-ended wrenches. One fixes the position of the body, the second rotates the flare nut.

The advantages of such a connection scheme are obvious: it does not require trimming and calibrating the edge of the pipe and can be done with your own hands using the simplest tool.

The price of ease of installation is a fairly reasonable reliability: with significant mechanical loads, it is quite realistic to pry the pipe out of the joint. Where do the loads come from? Offhand - at least with a water hammer that accompanies the flow of water; however, the games of children of active age are at least as destructive for plumbing.

Bell fitting

The second connection scheme is designed for annealed copper and uses its plasticity, the ability to deform under load. Tightness is ensured by a cone that baffles the end of the pipe, to which it is attracted by the union nut and the sealing ring. The joint is stronger and, more importantly, more durable: it will remain airtight, even with prolonged overheating, which is detrimental to rubber.

Instructions for assembling the connection in this case is much more difficult.

- The pipe is trimmed with a special knife.. The butt should be strictly perpendicular to its axis.

- Then the union nut and the sealing ring are driven over it..

- The edge is flared so that the cone seal comes in, after which it is attracted by a cap nut and a sealing ring to the body of the fitting..

- The hand-tightened nut is tightened with a pair of keys. Do not overdo it with effort: and to break the thread on the brass fitting, and break the cap nut easily enough.

Metal plastic

How are the crimp fittings for metal pipes?

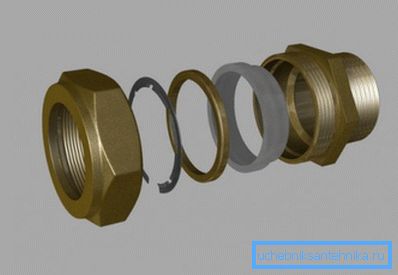

The pipe differs from most alternative solutions in its low ring stiffness. This property is compensated by the fitting, which is used as a mandrel: a split ring compresses the edge of the metal-polymer pipeline on its surface.

Additionally seal the connection:

- Fluoroplastic washer between the end of the pipe and the support site of the fitting. When tightening the nut, the butt is pressed against it by a tightening split ring.

- A pair of annular gaskets worn on the fitting in the grooves machined on its surface.

How are the crimp fittings installed on metal-plastic pipes?

- The pipe is machined with a knife for cutting metal-plastic.

By the way: the author is very good with a grinder with a cutting wheel for metal. The main thing - to make a cut, strictly perpendicular to the longitudinal axis.

- It is calibrated by any object of the appropriate diameter. The goal is to eliminate ovality near the butt.

- The chamfer is removed from the inside. This simple measure will help not to hush up the rubber o-rings.

- A cap nut and a split ring are driven off the pipe, after which it is put on the fitting. Rubber rings can be pre-lubricated with liquid soap. The main thing - do not break them and do not shift to the puck.

- The split ring is displaced to the end face, after which the cap nut is tightened - manually, then with a pair of keys.

Steel

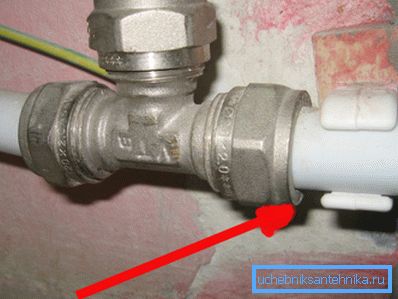

Compression fittings for steel pipes - ordinary, made of black and galvanized steel, and made of corrugated stainless steel - are arranged almost the same. Actually, their design exactly repeats the devices we have already studied for joining solid copper: the same cap nuts, retaining rings and O-rings.

How to mount such a connection in the case of black steel pipes?

- The surface of the pipe is carefully cleaned from layers of paint and rust. The work is easy to perform with a sharp knife.

- If ovality is present, it is eliminated. With some skill for this purpose, you can use an ordinary gas key.

Please note: it may leave deep scratches on the surface, which is unacceptable. If this happens, do not be lazy to remove the jam with a file.

- Gradually move the flare nut, split ring and seal to the end of the pipe.

- Insert the resulting structure into the body and tighten the nut with a pair of keys.

In the case of corrugated stainless steel, of course, the first two points can be omitted.

Polyethylene

Compression fittings for polyethylene pipes, unlike all those described above, are not made of metal (brass, copper or steel), but of the same polyethylene. Another significant difference is that they are mounted without tools: the nuts are tightened only by hand.

Useful: the maximum diameter of compression fittings for polyethylene, taking into account this feature, is limited to 32 millimeters.

The connection device is practically the same as those described above: tightness is ensured by a ring seal, which, when the cap nut is tightened, opens up with a stop ring. (See also Drainpipes: Features.)

How to mount the connection?

- All surfaces are cleaned from dirt.

- The outer chamfer is removed from the end. It will allow the pipe to enter the fitting with minimal resistance.

- The union nut, thrust and sealing rings are driven away from the end of the pipe, and then, after it is inserted into the body, back. The thread, as we remember, is tightened solely by hand.

Problems

Of course, it was not without them. We list the most typical problems of compression joints.

| Description | Cause | Elimination |

| Leak on metal with cyclic heating. | When mounting offset rubber rings. Cyclic heating caused deformation of the tightness of the polyethylene at the nozzle. | The joint is completely disassembled and reassembled with the correct installation of the O-rings. |

| Leak on pipe fittings with any kind of soft seal. | Seal partially lost elasticity. | Replacing the sealing ring. |

| Leak at the socket of copper pipes. | The crack of the tube, put on the tapered seal. | The tube is cut, re-threaded and flared. |

Conclusion

We hope that the material offered to the reader will help him in self-assembly and repair of plumbing. As always, the video in this article contains additional thematic information. Successes!