Conical pipe thread: features and marking

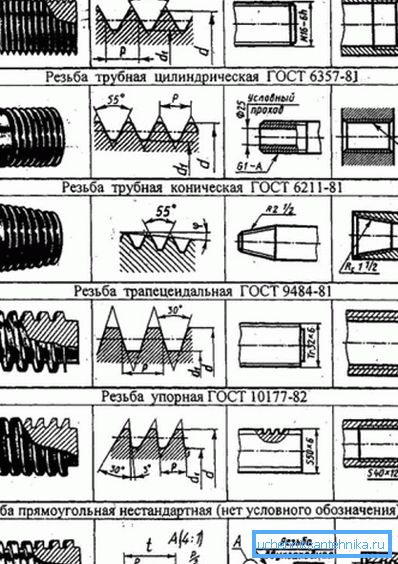

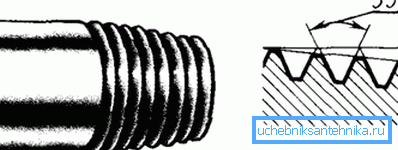

At connection of pipes the carving is usually used. It is a notch, which are performed on the inside and outside of the elements for subsequent docking by twisting. At the same time, there is a special GOST 6211 81 for pipe tapered threads, which allows to standardize this type of connection for ease of operation.

Features and labeling

First we need to say that there are many types of similar types of compounds. They differ in the shape of the teeth, the step width and length, but the principle of their work remains the same. Given this, a pipe conic thread is made according to GOST and is specially marked so that masters can distinguish all these types.

Benefits

First of all, it is necessary to say that this particular type of thread is most suitable for pipes. The fact is that when tightening the tip of the cone a little jammed, providing a good density of the joint and sealing. However, the instruction manual does not recommend constantly disassembling and assembling this type of connections, as this will lead to development.

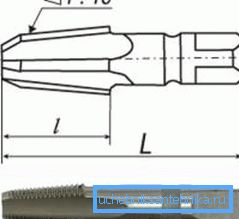

- Unlike other types of similar elements, such threads can be easily made by yourself.. To do this, you just need the appropriate die or tap. Other threads are very difficult to create with your own hands, especially if they are created on a material of large diameter.

- It is worth noting that for self-production of this type of compounds you need to purchase the appropriate tool.. Its price may seem quite large, but this cost is justified for the whole period of operation.

- It is necessary to mention that this type of external thread is great even for internal rectangular incisions.. Therefore, it is used most often.

Tip! Professional craftsmen try to avoid self-threading work. This is due to the fact that it is much easier to pay for this work when buying pipes, having calculated the location in advance, than to do it in an uncomfortable place with a conventional plate or tap.

Marking

First of all, this type of connection is designated by the letter R. At the same time, for the internal product, letter C is added to the marking. Therefore, the tapered tapered thread RC1 2 indicates that it is located inside and has a size of 1/2, which also determines the nominal diameter.

It should be noted that usually the pitch, height and length of such a connection depend on the diameter and increase proportionally with it. Therefore, it makes no sense to memorize the entire designation of a pipe conic thread, since it is much easier to use special reference literature.

Also, all plumbing systems are produced with the same parameters of such notches, which means that it is enough just to select products with the corresponding diameter.

Tip! When purchasing fittings or pipes for sewage with finished threads, you should immediately check the compatibility of all elements, which will also allow you to verify the quality of workmanship.

Recommendations of the masters

- Typically, the dimensions of the pipe tapered threads are selected in accordance with its diameter, since they meet the optimal connection criteria. Therefore, it is not necessary to engage in amateur and look for a tool to create another section. It is almost impossible and very impractical.

- When making threads yourself, it is worth using a small amount of engine oil to ease the stroke of the tap or the die on the pipe metal.

- When a thread is made, it is necessary to immediately remove the chips so that it does not fall onto the cutting surface and break the thread.

- For work use several taps or dies, which correspond to the rough and finish processing of the material.

Conclusion

After reading the video in this article, you can learn more about these types of compounds and their types. It should be concluded that although this work is quite simple, but everyone tries to avoid it, especially if you use hand tools. Much easier, better and faster to make cutting with the machine.