Connecting water pipes: methods for different materials

How to connect the water pipes with your own hands? In this article we will analyze solutions for the most popular materials, paying attention to their key problems, strengths and weaknesses.

So let's get started.

List of materials

To begin, remember what types of pipes are used in the construction of water supply networks.

- Black steel Recently, it has lost its former popularity due to the proliferation of polymeric materials, but still does not give up its position due to its high mechanical strength.

It should be clarified: in the centralized water supply networks, the nominal pressure is 3-6 kgf / cm2. However, in some cases (abrupt opening of valves or its malfunction during tests of the heating main for density) a short-term excess of this value is possible - up to 12 - 20 kgf / cm2.

- Galvanized steel pipe. It compares favorably with black steel with corrosion resistance.

- Corrugated stainless steel.

- Copper.

- Metal-plastic is a three-layer construction of cross-linked polyethylene and aluminum, which provides mechanical strength.

- Polypropylene (without reinforcement; fiber-reinforced; reinforced with aluminum foil).

- Polyethylene used exclusively on cold water supply due to limited heat resistance.

How to connect water pipes in each case?

Black steel

Welding

The main method of joining steel pipes is welding, electric arc or gas.

- Arc welding - it is the fusion of the electrode material, melted by an electric arc, with the seam insulation by the slag melt - the electrode shell. Large currents (200 amps or more) are provided by a welding transformer.

- Gas welding involves the use of the burner to reflow the edges of the weld flame, to which a mixture of oxygen and acetylene is fed. The weld material is the welding wire melted in the same flame.

Threads

Threaded connection, unlike welded, provides for the possibility of disassembly. The threads at the edges of the pipes are cut by hand, on a screw-cutting lathe, or simply welded.

For sealing threads can be used:

- Tape FUM. It is somewhat inconvenient in that it gives a leak with a minimum reverse course of the thread.

- Thread - sealant for connecting water pipes does not have this disadvantage; However, the price of 150-200 rubles for 30 meters of thread will not please everyone.

- Sanitary flax is cheap, but not too durable: it rots on cold water and burns out on hot.

By the way: the impregnation with paint, linseed oil or silicone sealant eliminates this problem, making the reel linen strand extremely durable.

Keyless fittings

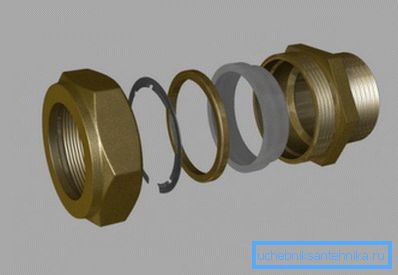

The steel pipe fitting is an uncomplicated design with a cap nut, spacer ring and rubber or silicone ring gasket. When tightening the nut, the pipe is securely crimped with a sealing ring.

The cost of a quick-tightening fitting starts from about 150 rubles; its installation requires thorough cleaning of the surface of the pipe from rust and paint.

Galvanized

The methods of its connection are the same as for black steel, minus welding. Heating with an electric arc or torch leads to zinc coating burnout and accelerated corrosion of the pipeline at the weld site, thereby depriving galvanizing of its main advantage - corrosion resistance.

Corrugated Stainless Steel

In this case, compression fittings with silicone sealing rings are used to connect the elements of the pipeline. Thanks to the corrugation, the fitting connection is extremely durable: it is almost impossible to pull the pipe out of the fitting without loosening the cap nut.

Copper

Copper pipe is connected in two ways.

Soldering

- The end of one of the elements to be joined is flared.

- The bell and the end of the second part are cleaned of oxides.

- After heating in the flame of the burner, a bar of solder is introduced into the socket. Due to the capillary effect, it quickly fills the cavity between the connected elements.

Compression fitting

Along with brazing, two types of compression fittings can be used to assemble copper plumbing.

- For an unannealed tube, an analogue of a fast-tightening fitting for a steel pipe is used. The seal is provided with a rubber ring.

- Soft annealed copper is flared and crimped with a cap nut on a stop ring of conic section.

Metal plastic

Metal-plastic water pipes and connectors for them can be mounted in two ways.

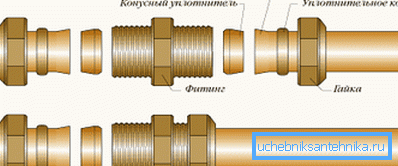

Compression Fittings

A calibrated pipe with a bevelled fit tightly onto the fitting fitting over a pair of sealing rubber rings. Then, a split ring and a cap nut with a conical internal section are successively driven to the fitting. Tightening the thread, a nut with a split ring compresses the pipe at the fitting.

This type of connection is considered less reliable because it often leaks after several cycles of heating and cooling.

In practice, the cause of faults is always the same - a gross violation of the technology of installation.

- For cutting instead of a trimmer knife, a regular metal saw is used.

- At the end of the pipe is not removed inner chamfer.

- The pipe is not calibrated, keeping the oval cross-section, acquired when reeling in the bay.

As a result, during the assembly, the ring seals are pulled out of the sockets and are displaced to the resistant fluoroplastic gasket of the fitting. Tightness is provided by a clamp to the fitting of elastic polyethylene, which, after several cycles of heating and cooling, is partially squeezed out of the place of greatest compression. As a result, several connection braces are required until the aluminum core is pressed against the fitting.

Press fittings

All the difference from the previous scheme is that here the pipe is crimped on the fitting with a stainless steel sleeve with the help of special tongs.

Pressed compounds practically do not flow, because:

- The grooves under the O-rings are made deeper; as a result, they are much harder to pull out during assembly.

- The use of expensive (about 5,000 rubles) ticks has the installer does not save on other tools. In particular, the pipe is not cut with a hacksaw, but with a miter knife; professionals also do not neglect chamfering and pipe calibration.

Polypropylene

For polypropylene plumbing also uses two methods of connection.

Welding

How to connect plastic water pipes using low-temperature welding?

Here is a list of the necessary tools.

| Tool | Functions |

| Low-temperature soldering iron (240 - 260С) with a set of nozzles | The melting of the surfaces of the connected elements |

| Tortsovochny knife | Cutting pipe size |

| Calibrator | Chamfering |

| Shaver, Facing Machine | Cleaning of aluminum reinforcement outside the pipe and between the layers of polypropylene, respectively |

Actually the technology is as follows:

- The soldering iron is equipped with a nozzle of the appropriate size and is heated to operating temperature.

- The pipe is cut to size with a miter knife.

- The outer chamfer is removed from the pipe with a calibrator.

- Aluminum foil (in the case of a pipe reinforced by it) is removed from the field of welding. It can cause stratification of the material and depressurization of the joint.

- The pipe and fitting are combined with the nozzle for a few seconds and after reflow are connected by a smooth reciprocating movement. After a short exposure, the stiffened plastic is almost as good as the monolithic section of the pipeline.

Push fittings

They can be used to connect plastic water pipes without welding. The push-fit is an uncomplicated design with an O-ring seal and a stainless steel locking ring with tabs that prevent the pipe from moving backwards; the final fixing is ensured by a cap nut with a conical inner surface.

How to connect plastic water pipes using a push fitting?

- The pipe is forcefully inserted into the fitting with a loose nut.

- The nut is tightened by hand until it stops.

Useful: on sale, albeit rarely, you can find push-fittings for metal-plastic.

Polyethylene

And here two ways of connection are popular.

Welding

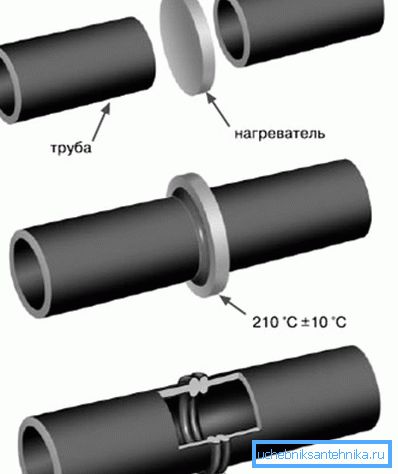

How to connect polyethylene water pipes by butt welding?

- Adjacent elements are faced, centered and pressed against the mirror of the soldering iron before reflow.

- Then the ends are pressed against each other and are aged until the polyethylene solidifies.

- The burr (which protrudes outside the pipe part of the seam) is trimmed.

End welding is used when connecting pipes with a wall thickness of 4 mm or more. With a large diameter, it requires the use of mechanical or hydraulic devices.

Compression Fittings

When connecting pipes of small sizes, plastic fittings with rubber or plastic seals are used.

How to connect plastic pipes for plumbing yourself with their help?

- A captive nut, two stop rings and an annular seal are successively driven onto the pipe.

- Then a fitting is put on its end.

- The seal is displaced in such a way that it enters the gap between the fitting and the pipe, after which it is pressed against the stop rings and clamped with a nut. The tool does not apply, the nut is twisted strictly by hand.

Conclusion

We hope that our express review will help the reader in choosing the best solutions for their own projects. More details about the methods of connecting pipes will allow the video in this article.

Successes!