Connection of metal-plastic pipes: 3 ways to create a

In the majority of cases, various polymer pipes are used for arranging water supply and heating systems. Depending on the type of plastic, fittings of one or another construction are used to connect them. Let us dwell in more detail on how to make the connection of metal-plastic pipes with your own hands.

Advantages of plumbing plumbing systems

Not so long ago, all plumbing systems were made of metal pipes.

However, now this material is superseded by metal-plastic, which has many advantages:

- easy installation;

- resistance to various chemicals;

- environmental friendliness of the production process;

- ability to withstand high internal pressure;

- flexibility so that fewer clutches can be used;

- no corrosion and deposits on the inner surface of the parts;

- long service life;

- low price

But there are some disadvantages:

- high coefficient of expansion from heat;

- metal plastic is destroyed by ultraviolet radiation.

Choosing a docking method

Connection of pipes from metal-plastic, as, however, and other types of polymer parts, is made with the help of fittings. From what kind of their you have acquired, depends on the method of assembly.

Consider each of them in more detail.

Method 1. Compression Compounds

In this case, connections for metal pipes are made using crimp fittings made from brass. Their other name is collet connection.

The advantages of this type of docking are that you don’t need to purchase any additional tools or equipment to work. Two wrenches are enough to tighten the crimp nuts.

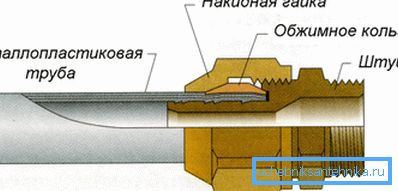

The fitting consists of three components:

- choke;

- split ring;

- cap nut.

Note! Connections of metal-plastic pipes using compression fittings are collapsible. If necessary, you can disassemble the plumbing system and mount it again, making the necessary changes or additions.

Installation instructions are extremely simple:

- A piece of the desired length is separated from the metal-plastic part. The blank should be straight at a distance of at least 10 centimeters from the cut.

- Cutting is carried out with special compression scissors or a hacksaw for metal. In the latter case, the edge will need to be cleaned of burrs. Remember that the cut must be carried out strictly at a right angle, otherwise it will be difficult to achieve a tight fit.

- Then a nut is put on the end (its thread should be directed towards the cut-off side) and a sealing ring.

- After this, the end of the part is processed by a special scan tool:

- the internal chamfer is removed by the calibration side (at a distance of about 1 mm);

- the other side of the sweep is removed outer chamfer.

- The fitting is inserted into the metal-plastic part, then a seal is put on it and the nut is screwed on. First, the work is done manually, then - with a wrench. Do not apply significant force to secure, otherwise the material may be damaged.

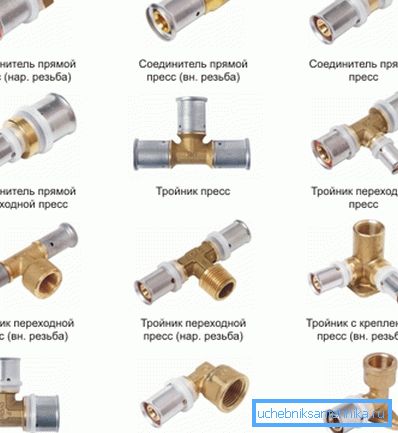

Method 2. Connect using press fittings

This option docking is used for arranging water supply systems and underfloor heating. Such connectors for metal-plastic pipes are used in cases when the pipeline is immured into a concrete wall or hides under a screed on the floor.

The joint turns out to be more reliable, but the installation itself requires certain skills from the master, as well as the availability of a special tool - press tongs.

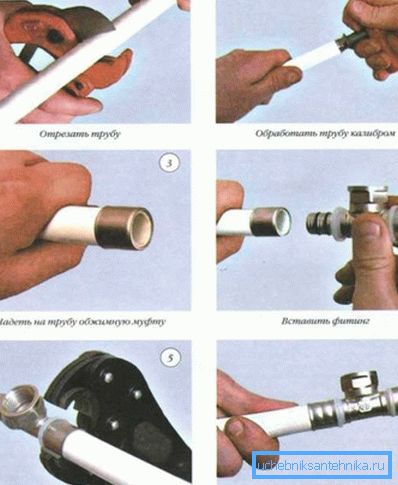

The work is carried out in the following sequence:

- The butt end of a properly cut pipe is processed by a reamer: the inner and outer chamfers are removed.

- The calibrator checks the internal diameter of the part.

- Before installing the fitting, make sure that a dielectric gasket and sealing rings are installed in it.

- A crimp sleeve is put on the part, and a fitting fitting with seals is inserted inside.

- Then the clutch is crimped on the pipe using press tongs. Make sure that the installed nozzles match the diameter of the part on which the fitting is being installed.

Note! Re-crimp the metal sleeve is not recommended. It is desirable that everything worked out the first time, otherwise leakage is possible, due to which it will be necessary to mount this node again.

There are types of press fittings with a rigidly mounted coupling. In this case, the control of the planting depth of the nozzle is carried out using a specially provided window.

Method 3. Docking using sliding couplings

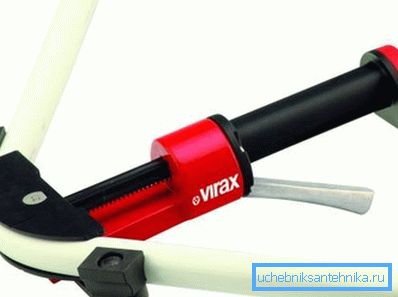

The second and third methods of connecting metal-plastic pipes are similar, but in the latter case, in addition to ticks, an expander is used, which increases the internal diameter of the part used before installing the fitting fitting there.

The connection is permanent, hermetic and very reliable. Used for installation of floor heating systems, which are supposed to be poured with concrete solution.

The work is done as follows:

- The pipe is cut off, after which a compression sleeve is put on it.

- The end of the metal-plastic part is expanded with an expander, then a fitting is inserted there.

- The coupling is crimped using a press.

- Reliable and durable connection is ready.

Connection of polymer pipes with metal

Sometimes it is necessary to connect pipes made of various materials. For example, to connect the local water supply with the central metal water mogul of an apartment building. In this case, you will need a crimp fitting and a caliber.

Note! To make the connection of a plastic pipe with a metal without thread will not work. It is necessary to use only special parts designed for a specific diameter of the pipeline.

Installation is as follows:

- A thread or special sealing polymer tape is wound on the thread of the metal part. The threaded part of the fitting is screwed onto it.

- Crimp nut and sealing ring push on the metal part, after which chamfers are removed from its edge.

- Then the plastic element slides over the fitting, which is bolted to the metal part.

- The nut is clamped on the fitting, sealing the connection.

Pipe bending methods

In addition to the connection, it is important to comply with the correct technology of bending metal-plastic parts.

There are four different ways:

- Manually. In this case, special care must be taken so that there is no defect at the point of inflection that will lead to obstruction of the pipeline.

- Using spring. This tool is sold in hardware stores. The spring is inserted inside, after which bending is performed.

- Using hair dryer. Under the influence of hot air metalplastic bends easier. But you should work with him carefully, otherwise there is a danger of melting the material.

- Using a special pipe bender. This is a professional tool that will help you bend a part of any size correctly and without much effort.

Conclusion

Docking polymer parts with each other, as well as the connection of metal-plastic pipes with metal - the work is simple, but responsible. From the correct action depends on the tightness and durability of operation of the water supply system. More details about this can be found in the video in this article.