Connection of plastic water pipes - we analyze all possible

Recently, the question of how to connect plastic water pipes is very relevant. With the advent of this material to the market, it began to gain more and more popularity every day.

Therefore, in this article we will give a detailed answer to this question.

Theoretical retreat

In order to successfully carry out this or that procedure, one should first carefully study all its theoretical aspects. In this regard, our first instruction will acquaint you with some important information.

Before you connect the water pipes, you must determine its type.

Plastic products have four classifications:

- PVC (based on polyvinyl chloride). Successfully used in both cold and hot water. The main advantage is the low price.

- Polypropylene (can have one layer or several). The presence of various reinforcing layers (for example, aluminum foil) gives such products additional strength. The maximum diameter is 125 mm (however, some manufacturers may make a larger sample to order).

Interesting: polypropylene pipes can be easily connected to steel.

- Polyethylene: it is smooth and corrugated. The latter are made from low pressure polyethylene. There is also the so-called cross-linked polyethylene, which is characterized by additional strength and resistance to the main stimuli.

Interesting: it got its name stitched due to the formation of additional bonds in the crystal lattice, obtained under the influence of very high pressure. These connections gave him higher technical characteristics.

- Metal polymers - are the highest quality among their fellows. It is worth noting the main property - the preservation of the form after a serious bend. It is also impossible not to isolate such indicators as high thermal and wear resistance, mechanical strength and very weak thermal expansion.

Recommendations for practical implementation

If you do not know how to connect plastic pipes for plumbing yourself, then the information below is especially for you. We will write out the procedure for each variety in detail.

Welded cross-linked polyethylene

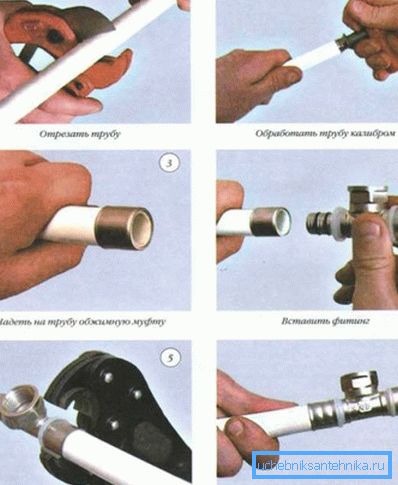

If we deal with cross-linked polyethylene, we proceed in this way:

- We prepare the following: appropriate coupling, two mounting sleeves, well-ground scissors.

- We cut off a piece of about 5 cm from the pipe with scissors. This should be done very carefully so that the line is strictly perpendicular. Do not allow even the slightest distortions.

- Then we put on the sleeve in the direction of the coupling.

- After which the product is flared using hydraulic tools.

- Insert the coupling into the prepared pipe and wait for some time (from one to several minutes depending on the size).

- On the connection we apply the tool as smoothly as possible. It is necessary to make so that the sleeve came all the way.

We connect hard plastic

If you are dealing with a hard plastic, the connection of water pipes with your own hands will be in a different scenario.

Consider it:

- Cut the pipe and clean the edge with a file. It is important to achieve maximum smoothness.

- Then you need to remove the scuffs with a thin file and make a chamfer on the outer edge.

- Then it is recommended to make a trial assembly in order to verify the correctness of the choice of fitting. To avoid problems in the future, mark with a marker a place of fixation. Then we make disassembly.

- Now it will be necessary to apply an adhesive substance to the surface that will prepare the material for further manipulations.

- Then we combine these elements in such a way that the previously marked marks are preserved. We hold them for a few seconds, so that the glue has time to grab.

- After 1-2 hours, the product will be ready for operation. If we are talking about hot water, then it would be advisable to withstand 6-8 hours.

Metal plastic

Before connecting metal plastics water pipes, you should decide on the type of fitting. There may be two, so consider the procedure for each of them.

Press fittings

When using such parts, special press machines are used. They are manual (they are familiar to many "ticks") and mechanical.

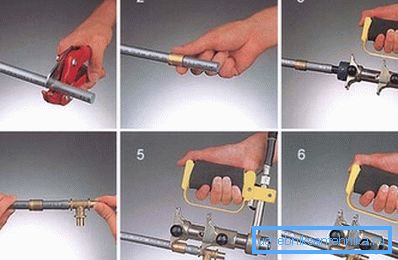

So, the connection procedure is as follows:

- We make cutting with precision scissors.

- Calibrator remove the internal chamfer. The external is deleted by the so-called phasmodus.

- Then we make a thorough check of the diameter, so that in the future there will be no problems.

- We remove the sleeve from the fitting and check its condition, then insert it back into its place.

- With enough effort, we insert the shank of the fitting into the pipe. Then the sleeve is placed in the fitting, and we join the handles.

Compression

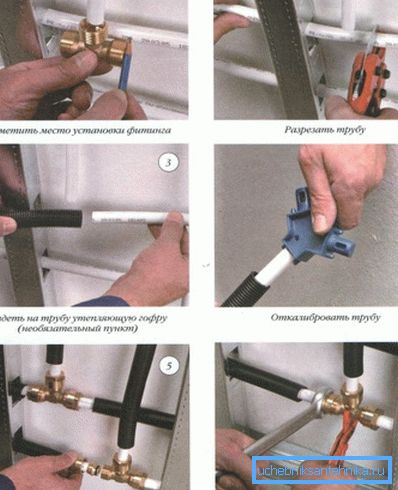

Now we will consider how to connect metal-plastic pipes for water supply using compression sleeves.

The procedure is not too complicated:

- We make cutting and chamfering, as in the previous example.

- We put a crimp ring and a tightening nut on the pipe.

- In the end with the help of two keys, you need to tighten these elements tightly to the stop.

- This work is completed.

Conclusion

On such an optimistic note, we finish our story. However, if you still have any questions, do not worry (see also the article Connecting parts of pipelines - types and their features).

In the presented video in this article you will find additional information on this topic, which will allow to understand everything.