Connection of polypropylene pipes: installation details

New technologies have long been firmly established in our home. With the advent of polypropylene pipes, the master no longer needs bulky equipment to mount the pipeline. In addition, the easy connection of polypropylene pipes with metal pipes makes it possible to use this material everywhere.

In this article we will talk about some of the advantages and subtleties of installation.

What are good such designs

For a relatively short time, this technology has firmly taken a leading position in the construction of domestic water lines.

Compared with metal and other types of plastic, polypropylene greatly benefits.

- Installation of this type of construction is easy and simple to perform. Technological instruction allows you to collect these lines, possessing basic knowledge and skills.

- As is well known, any metal is more or less susceptible to corrosion; plastic does not have this serious drawback. In this case, the warranty period of operation can reach up to 50 - 70 years or more.

- These communications do not overgrow from the inside. Salts and alkalis do not settle on polypropylene, which is very important for modern water supply networks.

- This material can be used both in the water supply system and in the heating system.

- The price of polypropylene is an order of magnitude less than that of metal, which causes a relatively low cost of construction.

- The main competitor of this material is polyethylene, but the connection of polyethylene pipes is made predominantly without welding, in a threaded way, it does not have great strength and requires regular maintenance. Plus polyethylene pipes do not withstand high pressure and temperature.

- A serious advantage is the compactness of the tool for mounting structures. The weight and dimensions of the soldering iron allow you to weld pipes in almost any conditions.

- Plastic piping is relatively lightweight. So, they do not require special, reinforced support structures.

Varieties of material

The market offers a fairly wide range of these products. The main criteria when choosing a brand are heat resistance and ability to withstand pressure.

The most common are the following types.

- PN-10 - maintain up to 10 atm, at a temperature up to 45? С. More suitable for cold water, sometimes can be used in the system underfloor heating.

- PN-16 - can be used for both warm and cold water. At a temperature of 60? C, they work stably under pressure of 16 atm.

- PN-20 - are a fairly common product, often used for arranging hot water lines as they can withstand up to 95? С and up to 20 atm.

- PN-25 - designed for pressure of 25 atm and temperatures up to 95? С. The walls of these pipes have internal reinforcement and can be used for the installation of central heating and systems with increased pressure.

Important: before installing the PN-25 pipe, it should be stripped of its edge from aluminum foil; for this purpose, the special shaver tool is used. Otherwise, you will not be able to dock the parts.

Subtleties of installation

When the pipe grade for the pipeline has already been selected, it will not be superfluous to decide on the type of connection. This choice is more dependent on the availability of a specialized tool.

Two words about connection types

The most reliable type of connection is considered to be soldering. The connection of polypropylene pipes with a diameter of up to 63 mm is usually performed through polypropylene couplings. The parts are soldered with a special soldering iron, complete with a set of nozzles for different diameters.

Special adapters are also produced with the help of which a metal pipe is connected to a polypropylene pipe or a polypropylene pipe is connected to a metal-plastic pipe.

Important: the soldering of pipes of large diameter is carried out end-to-end without the use of adapter sleeves. But in this way pipes with a wall thickness of more than 4 mm and a diameter of at least 50 mm are spliced. Plus a soldering iron for this requires a special one.

Often the question is asked, is it possible to connect polypropylene conduits without welding? Such a connection is possible, but only on cold, free-flow systems. This is done using crimp fittings, in addition, the connection is additionally glued with a special compound.

Important points for welding

Tip: the price of a professional soldering iron is quite high, if you don’t intend to work with them all the time, then it’s better to buy a small “amateur” unit that has several running attachments or be rented. The quality of the connection will not change.

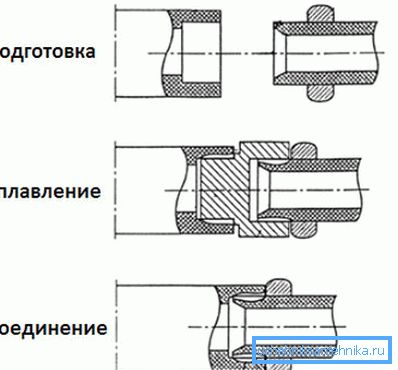

Each soldering iron comes with a stable stand. Professionals perform most of the connections with the stationary position of the soldering iron. Heats up the instrument for 10 - 15 minutes. The connecting nozzle consists of 2 parts, this is the sleeve into which the pipe is inserted and the drone, on which the coupling is heated.

Initially, the parts of the nozzle are installed on a cold soldering iron, and only after that, it turns on with the network. You can work after the indicators go out, on the second heating cycle. The heating time depends on the diameter, wall thickness and type of pipe. As a rule, complete with a soldering iron is a table in which all these values are indicated.

The very process of soldering is not a big deal. The pipe and coupling are put on the appropriate nozzles and kept for a specified time. After that, you need to quickly remove the parts from the nozzles and connect to the stop.

Important: during the connection of the parts do not need to turn or bend, they must sit tight and even. When the pipe is fully seated, the connection should be fixed in a static static position for a few seconds. It is possible to put the system under pressure after soldering in 15-20 minutes.

To mount the system on weight is somewhat more difficult. This requires some experience. When installing in difficult conditions, it is desirable to attract an assistant.

The whole difficulty lies in keeping the pipe and the coupling warm-up, then joining and fixing them.

The video in this article clearly shows the subtleties of welding.

Conclusion

As you can see, the connection of polypropylene pipes with their own hands does not require too high qualification. If you have a great desire, a soldering iron and material, then this work is quite possible for you.