Copper annealed pipe - what are the advantages

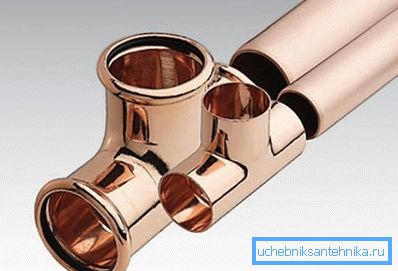

Copper pipelines began to do after they learned to melt this metal. Due to its unique properties, this material is still in great demand in various areas of production. Annealed copper pipe is the most popular product in this market. We will talk about the secrets of its popularity.

Secrets of annealing pipes

Each of us heard about such a common notion as hot iron. But the elevated fortress is not always good and in demand, in the case of annealing copper products, everything is done exactly the opposite.

How and why annealed material

In the process of copper melting from the ore in the first stage, a composition with a mass of unnecessary impurities is obtained. Experts call it rough copper.

To remove all this garbage, the alloy is blown with oxygen. After that, no more than 1% of side materials remain in it. But at the same time the alloy loses its elasticity.

After casting and rolling, the output is a hard, elastic material, this is the un-annealed copper pipe. In some areas of industry, of course, it is used, but the demand for it is not great. The maximum stretching of such a material is no more than 6%, which completely eliminates the possibility of bending.

Fortunately, this problem is solved quite simply. In special chambers that are filled with inert gas, the material is heated to a temperature of 600-700? С. Further, the pipe is slowly cooled in a natural way; in the language of professionals, this process is called tempering.

As a result, the strength of the product at 340 MPa slightly decreases, but still remains at an acceptable level of 210–220 MPa, such a pipe can withstand up to 200 atm. But the ability to stretch increases 1.5 - 2 times.

The difference between the annealed and unannealed copper pipe is significant. In particular, if you want to bend unannealed material at any angle, then you will not succeed. In addition to the fact that significant efforts will be required, the pipe will eventually burst.

Important: during roasting in an inert gas furnace, the product acquires additional properties. But if you are faced with not annealed material during installation of the system, it is enough to warm up the right place with a heating pad. After cooling, the elasticity of the heated sector will increase significantly.

Material advantages

- Due to the high elasticity, the pipe layout can be bent at any angle. In addition, such pipes are easily stretched using a tool such as a pipe expander, which allows you to solder the sector without using additional couplings to connect pipes. As is known, a monolithic system is much more reliable, plus the price of such structures will be much lower.

- Copper, fired structures tolerate both low and high temperatures.. The amplitude is from -200? C to +250? C. In addition, they are not afraid of sudden changes in temperature and pressure.

Important: resistance to positive temperatures is limited by the melting point of the solder, through which the sections are joined. For soft low-melting solders, this value is in the range of 180 - 250? С. Refractory materials can withstand up to 500? С.

- In view of the good plasticity of the material, it can be rolled into coils with a large meter. This opens up additional opportunities for storage, transportation and installation of structures.

- The material is environmentally friendly, moreover, thanks to the technology of annealing in furnaces filled with inert gas, the inner surface of the pipes works as an antiseptic, it can disinfect drinking water. Solder, which contains silver, only enhances these qualities.

- Being covered with a dense oxide film, the material does not corrode further, in other words, such pipes do not rust in aggressive or oxygen-rich environments..

- As mentioned earlier, structures are able to stretch up to 1.5 - 2 times, practically without losing their performance or cracking.. As a result, even frozen water does not tear, but only stretches the pipe.

- Instructions for the installation of such structures with their own hands is understandable and accessible for mastering even to amateurs.. Water systems in the house can be soldered with the usual soft solder, using any burner that is capable of producing 700 - 900? C. The elasticity of the material allows it to be bent by hand.

- The durability of such pipes are legendary.. Leading manufacturers claim that the copper plumbing system is able to serve up to 100 years. Perhaps, of course, this is an advertising move, but the material is really hardy.

Material disadvantages

- Of the clearly highlighted minuses immediately focuses on the high price of the material and the high weight of the products. You can’t argue with this anymore, but the water supply or heating in the house is not established for one day, and the principle is already working here, made and forgotten for the rest of your life.

- Before that, we talked about the fact that annealed pipes have high elasticity and it is convenient to work with them. But the same elasticity can be a significant drawback, soft material is easily damaged, a heavy object is dropped, or a careless hammer blow, instantly changes the cross-section and appearance of the pipeline.

- The material has a high thermal conductivity. Using such cabling for transporting hot water, there is always the possibility of injury. Although at the moment, this minus is easily corrected by the arrangement of thermal insulation.

Important: the quality of products is regulated at once by several regulatory documents. If we talk specifically about the annealed material, then for it there is GOST R-52318-2005, in Europe it passes as EN 1057. There is also GOST 617-90, which regulates the quality of all copper pipes.

Material Use Areas

In private and municipal construction, it is of course both hot and cold water supply, plus any liquid heating systems. Well-mounted copper pipelines have a decent appearance, and many interior designers successfully use these qualities.

Copper is neutral to aggressive environment, well keeps outrageous temperature and pressure. This quality is highly valued in air conditioning systems and refrigeration units for any purpose.

The video in this article shows the subtleties of working with copper pipes.

Conclusion

In any system there are certain drawbacks, they also have copper structures. But nevertheless, it should be recognized that annealed copper pipe with proper installation will not only look decent and solid, but will also serve your grandchildren.