Copper pipe soldering: 3 mounting methods

One of the most reliable materials for building various pipe networks is copper. Pipes from this metal have a long service life, the widest range of operating temperatures and high strength. The theme of the material below is the soldering of copper pipes with your own hands.

Having mastered this process, it will not be difficult for you to mount such an engineering network at home.

Types of compounds

Low temperature soldering parts

This technology of soldering copper pipes is used for the installation of engineering networks of heating, plumbing and other similar systems, where the temperature of the transported fluid does not exceed + 130 degrees Celsius. The flame from the gas burner in this case heats the product no higher than + 450 degrees Celsius, and the size of the part is 6-108 mm (see also the article Fittings for polypropylene pipes: types and their technical description).

As a solder for low-temperature soldering, various soft metals are used: lead, tin, and so on. It is from here that this method is called “soft rations”. The width of the seam, depending on the size of the fittings, can be 7-50 mm.

The considered connection is very common when installing various plumbing systems.

This is due to the following factors:

- when low-temperature soldering does not occur annealing of copper (which affects the strength of the pipeline);

- the work process is less time consuming and safer;

- used only for the manufacture of water transport systems;

- cannot be used to connect gas pipelines.

High temperature soldering parts

In this case, copper tubes are soldered at a flame temperature exceeding + 450 degrees Celsius.

It uses solder based on the following metals:

- copper;

- silver;

- other alloys harder than tin.

The use of this technology makes it possible to obtain an all-in-one joint, which has increased strength and withstands a much higher temperature of the transported medium.

Another name for the compound is brazing.

Brazing of copper pipes is used in the following cases:

- connection of parts larger than 28 mm;

- docking of parts intended for the transport of fluid, whose temperature exceeds 130 degrees Celsius;

- manufacturing of heating systems (this method of connection allows you to divert from the existing engineering network without deteriorating the technical characteristics of the latter).

- the use of exactly soldering provides for installation instructions for gas pipeline systems.

Note! During high-temperature soldering, copper is annealed, as a result of which the pipe loses its strength. To minimize this phenomenon, it is necessary that the cooling of the seam occurs naturally, and the heating during soldering is as low as possible.

Cold mix of parts

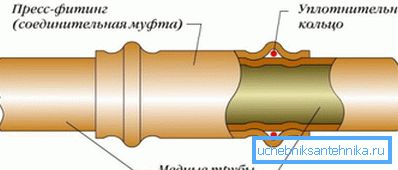

There is also a connection of copper pipes without soldering. For this purpose, special crimping couplings are used, the design of which is similar to similar products used when working with polymer parts.

Externally, the cold coupling is similar to the brazing fitting. However, the first is additionally equipped with rubber seals from special polymers.

In addition, there is a detachable connection of copper pipelines. For this purpose, a collet fitting is used.

They are divided into two types:

- for joining solid and medium hard parts;

- for the connection of soft and semi-solid products.

Work process

Considering the high cost of soldering copper pipes (in case you hire a specialized team of plumbers for this), it may be recommended to do all the work yourself, especially since the price of semi-professional gas burners makes them quite affordable.

Let us consider in more detail each of their compounds.

General moments

Heating of the pipe and solder during low-temperature brazing of copper pipes is performed using a gas burner.

Different gas mixtures serve as fuel:

- air-propane-butane;

- air-propane;

- air-acetylene.

Note! In some types of work the use of an open flame is not allowed. Then the heating is done with electricity. This does not affect the speed of work, but this way you can only dock products of small diameter.

With regard to brazing, here to reach the desired temperature can only be using an open flame.

Sufficient heat can be produced using the following fuels:

- air-acetylene;

- oxygen propane;

- oxygen acetylene

Using the latter combination, the acetylene pipes are directly welded (without solder). The flame temperature in this case should reach the melting point of copper (from 1070 to 1080 degrees Celsius).

In the hardware stores there are many devices with which you can make copper pipes.

They can be divided into two main categories:

- portable burners with disposable balloon for home use;

- universal gas burners designed for the use of large containers and professional work.

The general scheme of welding copper pipes work is as follows:

- cutting the pipe and stripping the end of the burrs;

- cleaning to the characteristic copper luster of the inner and outer parts of the pipe on which the fitting will be put on;

- control of the location of connectors and gaps between them and the pipe;

- application of flux to the outer part of the pipe (not necessary in all cases);

- assembly of the connecting node;

- heating of the docking site;

- filling the special mounting gap with the solder used;

- termination of heating;

- gradual cooling of the seam;

- removal of flux residues and excess solder.

Pipe preparation

Cut copper parts using the following tools:

- special cutter - it does not form burrs, but can lead to a decrease in the internal diameter of the part due to the bend inside the edges;

- hacksaws on metal - does not form a bend, but at the junction many burrs appear that must be disposed of before soldering.

Note! Edge jam (when using a torch) leads to a decrease in the external diameter of the pipe and, consequently, an increase in the installation gap. As a consequence, after soldering the connection will not be tight. According to the instructions, the size of the mounting gap can be 0.02-0.4 mm.

The end of the pipe after cutting should have a strictly round shape. The manual calibrator helps to achieve this. Its use ensures the correct size of the installation gap.

The flux should be applied to the pipe immediately after it has been stripped. It is strictly forbidden to lubricate with this substance the inner surfaces of the connecting fitting.

As soon as you have applied the paste, the parts need to be joined immediately, otherwise dust or other foreign particles may get on the wet end. It is necessary to push the pipe into the socket to the stop, slightly rotating the fitting around its axis, which allows for a more even distribution of the flux. Before heating, residual paste on the pipe must be removed.

Features of heating with low-temperature soldering

For work you will need:

- flux for soft soldering;

- propane burner;

- gas mixture.

Soldering copper pipes with tin solder can be a special soldering iron, which also produces heating fitting.

The work is carried out in the following sequence:

- The flame of the burner must be constantly moved around the joint, performing uniform heating of the entire part.

- Touching the end of the solder of the mounting gap, it is necessary to check if the tin does not start to melt. If not, warming continues.

- As soon as the solder melts, heat must be stopped to allow the tin to fill the capillary gap in the fitting.

The tightness of the connection is ensured by the fact that the solder melts and fills the gap between the fitting and the pipe.

Note! With low-temperature soldering, warm-up should stop immediately after the substance begins to fill the installation gap. Otherwise, you can overheat the connecting node, which will reduce the strength of the pipeline.

As soon as the solder melts, it is necessary to allow the compound to cool down independently, since soft tin is a very fragile substance.

During soldering, it is important to avoid overheating of the parts, otherwise the flux may collapse and will not be able to remove the oxides that appear.

Instead of a burner, you can use a special electric soldering iron, which consists of electric tongs and a power supply unit. The sequence of operations in this case does not differ from the above.

Sequence of operations during brazing

For operation, propane or acetylene burners mixed with oxygen should be used.

While working, you should pay attention to such nuances:

- Heating must be done quickly but evenly.. The torch should be constantly moved along the entire length of the fitting.

- The flame should have a bright blue color.. Details are heated to a temperature of 750 degrees Celsius (they acquire a characteristic dark cherry color).

- If the heating was performed correctly, the solder that is fed to the mounting hole should start to melt.. You can preheat it in the flame of the burner.

- The essence of the work is that it is necessary to achieve the lowest possible heating temperature at which the solder begins to melt. It is desirable that with a single touch of the fitting, the solder immediately fills the capillary hole.

As soon as the connecting node has cooled down, all flux residues should be carefully removed from the pipe. If the plumbing system was installed, thoroughly flush all pipes to remove the flux inside. It is an aggressive chemical that can harm human health.

Cold mix

The technology of connecting soft copper pipes using press-fittings does not cause difficulties and boils down to several simple sequential actions:

- cutting pipe of the right size;

- deburring the end of a burr and giving it a round shape;

- insert the fitting of the press fitting into the pipe;

- pipe connection using a sliding sleeve (special pliers are used).

Conclusion

Brazing of copper pipes with tin or hard solder is the main way to connect such parts. The tightness and strength of the seam depends on the correctness of the performance of all stages of work (see also the article Polypropylene pipes and fittings: features, standards, installation tips).

You can learn more about this process from the video in this article.