Couplings for pnd of pipes and other ways of their

What are the couplings for pipes HDPE (low pressure polyethylene)? Do different types of fittings have any specific features? What other, besides coupling joints, ways can spliced pipes?

Let's figure it out.

Couplings

Scroll

Let's list all types of couplings used for polyethylene pipelines.

- Compression Fittings - collapsible using rubber ring seals. When tightening by means of a stop ring, the union nut expands the seal; that, in turn, tightly clings to the pipe and seals the connection.

- Electrowelded couplings for pipes PND - a kind of permanent connection in which to heat the adjacent surfaces the heating coil pre-installed by the manufacturer is used. The use of electric-welded fittings allows you to do without a soldering iron: you just need to apply for a pair of contacts 12 volts from a step-down transformer or battery and to withstand a certain duration of heating.

Curiously: recently transformed welding transformers with barcode reader. When reading the markings, they receive information about the voltage, warm-up time and cooling of the fitting.

However, this information is present in the designation and in the form available for visual reading.

The strength of the connection in an electrofusion method is not inferior to a solid pipe. The only serious disadvantage of these fittings is the rather high price. We give retail prices for the most popular sizes of straight couplings without changing the diameter.

| Diameter, mm | Retail cost, rubles |

| 20 | 145 |

| 25 | 150 |

| 32 | 155 |

| 40 | 170 |

| 50 | 247 |

| 75 | 410 |

| 110 | 650 |

- Flared connections used exclusively for the installation of free-flow sewage. Pressure head PND pipes with diameters of 50, 110 and 150 mm are fully compatible with the sewer fittings of the corresponding standard sizes and are often used instead of the more usual PVC-U pipes. The reason is much better acoustic characteristics of polyethylene: thick and elastic walls almost completely quench the sounds of the movement of drains.

Installation

How to connect the pipes with the help of a compression fitting?

- The pipe is trimmed with a special knife. In his absence, you can use the usual hacksaw with the subsequent processing of the edge with a file. The cut must be exactly perpendicular to the longitudinal axis.

- The chamfer is removed from the inner and outer sides of the pipe. It is better to use a calibrator for this work, but, in extreme cases, a sharp knife will do. The goal is to prevent the butt from bulging or displacing the rubber seal.

- The union nut, the clamping and thrust rings and the annular rubber seal are successively put on the pipe, after which its end is inserted into the coupling housing.

- Rings and a nut are driven to the edge and twisted by hand.

How is the welding of HDPE pipes using an elektromuftovy method?

- The pipe is fingered and cleaned up from garbage.

- After it is inserted into the fitting, its contacts are energized for the time indicated in the marking.

- At the time of cooling section of the pipeline retains complete immobility.

And what about the installation of sewage using couplings with rubber seals?

The subtleties are only two.

- The outer chamfer is removed from the end of the pipe. This work can be done with a sharp knife: polyethylene is easily cut.

By the way: in contrast to polypropylene, the Bulgarian cannot be used for cutting and chamfering a polyethylene pipe. This plastic has a lower melting point and just flows with the heating that is unavoidable during abrasive processing.

- A simple instruction will help reduce the effort required to assemble the joint: a little soap, liquid or ordinary, should be applied to the sealant.

Problems

In some cases, the compression couplings for connecting the HDPE pipes start to flow under pressure. The reason is always the same - the wrong build.

Instead of putting all the rings on the pipe, it is inserted into the fitting with a loose cap nut; together with poor-quality processing of edges, this leads to the fact that the end of the pipe does not fit into the annular seal, but rests against it.

The way to fix the problem is obvious: it is enough to remove the inner chamfer and reassemble the joint, controlling the position of the seal.

Alternatives

Is it possible to do without coupling fitting when installing a polyethylene water pipe?

Butt welding

When assembling pipelines with a small internal pressure, manual butt welding is practiced using a primitive soldering iron - a flat heating element with a teflon coating.

After it is heated to 210–220 ° C, the ends of the pipes are pressed against it and, after reflow, are combined. After cooling and stripping of burr (melt extruded outside the weld seam), the strength of such a joint reaches 60-80% of the strength of a solid pipe.

However: for pressure water pipes it is strongly recommended to use soldering irons with mechanical alignment and controlled clamping force.

Fittings for cross-linked polyethylene

Along with the usual polyethylene, the installation of water supply systems often uses the so-called cross-linked one. Due to the simple modification, its molecules form not only sequential, but also cross-links, which dramatically increases the heat resistance and mechanical strength of the polymer.

One of the properties that stitching gives this plastic is mechanical memory. When deformed, the pipe quickly returns to its original state.

This property is used when installing with the help of fittings:

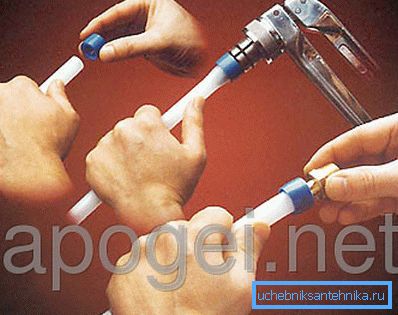

- The pipe expands with the help of a special tool - extender.

- The fitting is inserted into the socket.

- The pipe which is narrowed and reliably pressed on the union is in addition fixed on it by a collar.

Conclusion

We hope that the material offered to the reader will help him to choose the most suitable method of installation for his case.

As always, the video in this article contains additional thematic information. Successes!