Couplings for polyethylene pipes: 6 main types

Plastic pipes confidently entered our lives, surrounding the water, gas and sewer systems. Affordable price, light weight and durability guarantee their widespread popularity.

And various types of couplings also greatly simplify installation work. About them and will be discussed in this article.

Merits

Before proceeding to the educational program for clutch classification, let's take a look at their advantages:

- A wide range of applications. They are used in networks of pressure and non-pressure water supply, gas pipeline systems and sewage systems.

- Lack of temperature change in volume.

- Resistance to working pressure.

- Immunity to corrosive processes.

- Variety of shapes and sizes. In addition to the classic, there are many corner joints, tees, crosses and others that facilitate the laying of pipe components of any diameter.

- Durability. PVC pipes themselves are famous for their long service life, the fitting is not inferior to them in this.

Species

We already mentioned in merits that there are couplings for various pipelines of various shapes and sizes. In addition, they may still differ in their technical parameters and method of installation.

By area of use, their classification is as follows:

| Scope of application | Suitable types of fittings |

| Gas supply |

|

| All types of water pipes |

|

| Sewage |

|

And now we will consider them in more detail:

Thermistor

Installation Instructions:

- We connect the welding equipment to the terminals coming out of the copper winding located inside the fitting.

- Turn on the device.

- Copper is heated by electric current.

- The material of the coupling under the action of high temperature melts, securely fixing the connection pipe.

High reliability is overshadowed by the relatively high cost of these components and the need for a welding unit for their successful installation.

Cast

Possess increased resistance to pressure and are used mainly in the pressure water supply and gas pipelines located underground. Installation is carried out by butt-welding.

Tip: if you doubt your skills in handling welding equipment, it is recommended to invite a specialist. In the opposite case, a poorly made connection may lead to rupture, which will require expensive repairs.

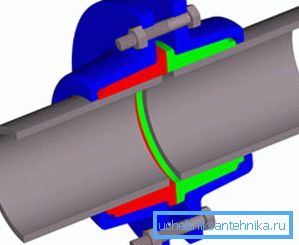

Compression

Compression fittings are extremely comfortable to use. In them, fixation is carried out by pressing in the crimping ring with a special sleeve, which excludes the possibility of unwinding with hydraulic shocks and different types of vibrations.

The following advantages can be highlighted:

- No need to use a welding machine.

- The possibility of re-use.

Tip: before re-use, be sure to replace the sealing ring. This is the only element subject to wear.

- Ease of use with your own hands. For the installation work does not require any special skills, and their speed increases significantly.

- Versatility. Used in combination with pipes of any materials.

- Low price.

Compression coupling for polyethylene pipes consists of several components:

| Element | Purpose |

| Housing | Protects the junction from external influences |

| Cover nut | Carries out tightening and fixing the product |

| Sealing ring | Seals the joint |

| Clamping ring | Stabilizes sealing ring |

| Push-in sleeve | Pushes the clamping ring |

Segmental

These are prepared segments of polyethylene pipes, which are also installed using butt welding at a certain angle.

Distinctive features:

- Low cost.

- High quality weld.

- Allowable pressure 2.5 MPa.

- Maintain temperature to +40 degrees Celsius.

Flange connections

The main element of the seal when using flanges are paronitic gaskets.

Pros:

- High tightness of docking elements.

- High speed assembly and dismantling.

- Simplicity of assembly with connection of various capacities, devices and driving elements of mechanisms.

Corrugated

If the water supply is free-flow, then the possibility of cheap connection of its components with the help of corrugated products is allowed. The seal in this case is a special rubber gasket inserted into the inside of the socket.

Conclusion

Polyethylene pipes are currently used in the creation of water pipes, gas pipelines and sewers. Their connections are made with the help of special couplings, which guarantee full tightness and long-term functioning.

Above, we have reviewed all existing types of fittings and features of their operation.

The video in this article will acquaint you with additional information directly related to the materials presented.