Crimping metal pipe

When working on the installation and operation of heating and water supply systems, it is often necessary to connect pipes to each other. Earlier, when only metal pipes were used, the question was solved in most cases with the help of a threaded connection. However, with the development of the chemical industry, metal-plastic pipes have become quite widespread, and it is not possible to organize a firm and tight connection using threads. The way out of the situation is the technology, referred to as crimping metal-plastic pipes, in which the elements are interconnected by special connecting elements. How exactly to do it and what are the nuances that will exist will be discussed further.

The essence of the process

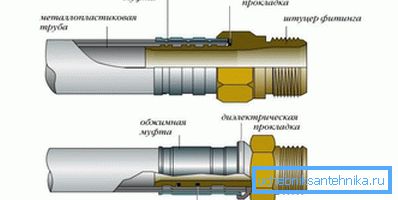

For the crimp connection of metal-plastic pipes, special connecting elements are usually used, called fittings. They may have some structural differences from each other, but mainly consist of the main part inserted into the pipe and the compression ring (it is also called the sleeve), which is worn on the outside of the pipe and serves for direct crimping.

As a result of using such a connecting element, a tight and durable connection is obtained, which does not require the use of any special seals. It should be added that the connection does not need any complex technical devices, and you can do all the work with your own hands, which will save money and speed up the process.

Stages of work

All work steps must be carried out with the utmost care, as well as safety regulations.

- The first thing to do is to measure and cut to size the pipes to be connected. For cutting of such pipes special nippers are used. To bring them to the working position, the arms are separated to the maximum. Next, making squeezing movements with handles, you need to cut the pipe in the right place, then rotate it a little and continue cutting. So, gradually turning the pipe, it must be cut off completely.

- Next, the pipe must be calibrated. The fact is that when cutting it most often becomes oval, and this defect is eliminated with a special calibrator. The device is inserted into the pipe and with the help of rotational movements aligns the end of the pipe to a round shape. This is done by removing the inner chamfer from the pipe. This action is necessary so that the connecting nipple is inserted into the pipe as easily as possible and the rubber seals are not damaged.

- After this work is performed, a compression sleeve is put on the pipe. It resembles a wide washer and comes with a fitting.

- Then the main part of the connecting element is inserted into the pipe - a nipple. It is necessary to ensure that all rubber gaskets, which are provided for its design, were in place. Also do not forget about the presence of a special sealing ring. By the way, it is necessary not only as an additional sealant, but also in order that the fitting metal and the metal mesh that is part of the pipe do not come into contact and do not corrode.

- When the joint is ready, you can proceed to the direct crimping. A special tool must be used for it. These can be electrical or mechanical press tongs. Power tools of this type can be found only in specialized organizations, so that the description of his work is impractical, but mechanical press tongs are a more common tool and recommended for use at home. To bring it into working condition, the handles must be rotated to the sides by 180 degrees, then open the working crimp head, into which you need to insert special sealing bushings corresponding to the diameter of the pipe. After that the tool is placed on top of the junction and by squeezing the handles, the coupling is crimped around the pipe and the fitting inserted into it. Then the handle is bred to the side and the press tongs are removed.

As a result of the described manipulations, a tight, strong and tight connection is obtained. The method is simple to use and universal. It can be used when connecting pipes that are supposed to be disguised and which will not protrude. Connecting fittings of this type are available in a wide variety of shapes and configurations and can solve a fairly extensive range of tasks.

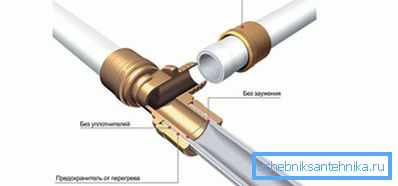

Sliding press fittings

It is worth noting that the above described method of crimp connection of metal-plastic pipes is not the only one. Here it is worth mentioning the connection with the help of so-called sliding press fittings. This method is used in cases where a more dense and reliable pipe connection is required. As a rule, this is necessary if the estimated pressure in the pipes is significant. The essence of the process as a whole is similar to the previous method, but it has certain features.

- At first the pipe is also cut to size.

- Next, it is put on the crimp coupling.

- Then the end of the pipe must be treated with a special tool called an expander. His job is that he will expand the end section of the pipe and the result will be something like a socket.

- After these works, a fitting is inserted into the pipe.

- After that, with the help of a special hydraulic press, the coupling sleeve slides towards the joint. This in itself will give a fairly tight connection.

- The final stage of the work is the final fastening of the joint, for which a special crimping press is used, which will create the strongest and most tight joint.

As in the previous case, there are plenty of types of connecting fittings suitable for this method. On the market you can find elements of a variety of modifications and configurations.

Tip! For work with a specific type of pipe manufacturer recommended a specific type of connection, as well as well-defined models of connecting fittings.

Among the arguments in favor of the described methods of connection can be called technological simplicity of work and tight, strong and durable connection of pipes. However, in fairness it should be said that there are certain disadvantages. More precisely, the disadvantage is not the connection method itself, but the fact that using it requires the use of a special tool, which not everyone has. Acquisition of press ticks for a one-time connection is hardly advisable, but you can try to rent a tool and many shops make such concessions. The rest of the method is characterized only from the positive side. For a complete understanding of the process, you can get acquainted with the relevant videos that will help to understand all the intricacies.

Video

This video shows the pipe crimping process.

Another video that will help you in your work.