Cross-linked polyethylene pipes as a modern material of

Heating pipes made of cross-linked polyethylene is one of the most reliable and successful materials for the installation of heating circuits. In addition, PEX (the so-called material) is also suitable for cold water supply, and for other purposes. We will talk about its advantages and technical characteristics, show you how to properly install the connecting fittings and describe what constitutes a tool for pipes made of cross-linked polyethylene.

Crosslinked polyethylene

Specifications

Technical characteristics of pipes made of cross-linked polyethylene can immediately remove a number of questions from skeptics, and experienced plumbers will see a lot of advantages and unexpected possibilities.

We list the most important and characteristic features of the material in terms of its operation and installation:

- Fatigue strength is a very important indicator on which the durability of a material and its quality depend. PEX differs remarkably high fatigue strength, even in the mode of extreme water temperature up to 95 - 97 degrees;

- Unlike many, and more precisely, from most types of plastic pipes, in the case of PEX, no temperature deformation or shape change is observed up to two hundred degrees heating;

- The material does not crack. At all. Never, even at low temperatures;

- It is distinguished by high impact strength, as well as impact and notch viscosity, which is observed even with strong cooling - up to 50 degrees of frost;

- Presence of effect of the return shrinkage or "memory of the form". That is, with minor changes in the configuration of the product, it quickly returns the original look;

- Practically optimal ratio of flexibility and strength, which makes the system reliable, and installation is simple;

- The absence of dangerous ions, halogens or heavy metals, environmental and toxicological safety;

- High durability of surfaces, especially abrasion;

- The ability to use hot water as a working medium, both for underfloor heating and radiator heating. The same goes for hot water supply;

- Complete chemical inertness to aggressive compounds and reagents;

- Durability.

Note! The structure of the product has a special system of layers of different composition and purpose: it allows you to achieve these indicators.

Connection methods and tools

The installation of pipes made of cross-linked polyethylene with your own hands may seem complicated, but this is not so (find out here how to cut the pipes).

There are two main ways to connect pipes and fittings:

- Using compression fitting;

- With the use of a press fitting.

Note! In the first and in the second case, a special tool is needed for pipes made of cross-linked polyethylene, which will make all the work simple and even interesting.

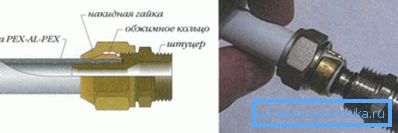

The compression fitting is a nut that is screwed on and squeezes the split ring. Reliable and quite working method.

We will talk about how to work with a press-on fitting type, as this method has shown itself in different areas and causes some confidence.

Installation of a press fitting

In this section, we show how you can quickly and efficiently mount a PEX pipe with a press fitting or a sleeve with your own hands.

For work, you need an expansion gun with nozzles for different diameters, scissors for cutting pipes at a right angle and a press-on vice.

The rest will tell the instruction:

- The end of the product is trimmed as smoothly and carefully as possible with special scissors.. The cut should be at 90 degrees to the pipe itself, the burrs and other defects are removed;

- Then they put a sleeve on the edge, which will be pressed later.. It is important to remember that the sleeve is worn before you expand the inlet of the product itself, otherwise it will simply not fit;

- After that, the nozzle of the desired diameter is selected, which with the help of a special pistol expands the end (inlet) of the pipe by several millimeters in diameter. The gun can be both hydraulic and battery;

- Insert the fitting into the expanded hole;

- We press the sleeve with a vice to the end, but carefully so as not to damage the connection.

Note! The kit for assembling PEX systems has a tube of grease. It will help insert the fitting into the socket without much effort.

Conclusion

PEX systems or products made of cross-linked polyethylene are an excellent substitute for cast-iron and steel pipes for heating or water supply. Even Russian-made cross-linked polyethylene pipes have all the advantages of this technology, and the video in this article perfectly demonstrates this (also learn how to solder copper pipes).