Dimensions of profile pipes: the most important

Profile pipes are a special type of rolled products. These products have a non-standard cross-section configuration.

It, unlike the usual - round, can have the form:

- a rectangle;

- square;

- diamond;

- oval

- rectangle or square with rounded edges, etc.

Areas of use

Such products are not used in engineering communications, but as frame elements of metal structures. The hollow member has almost the same rigidity as a solid bar. At the same time, the hollow analog is 30/40% lighter.

Note! The use of such elements in the construction of metal structures makes it possible to reduce their weight and cost (less material - lower price). The size and strength of the structure will be unchanged. However, provided that during the production of the product, its dimensions are controlled.

Why parameters are controlled

- The described elements are used in loadable structures.. On this basis, and a small deviation from their stated size can adversely affect the strength of the frame of the profile tubes.

- If the size and weight of the profile pipe are non-standard, you can expect anything from it.. For example, it can weaken the structure (if it is thinner than necessary) or increase its weight (if the parameters are larger).

- Design calculations of the stiffness of metal constructions beams are based on standard dimensions.. Their values are announced by the respective GOSTs. The instruction warns that if the dimensions do not meet the standards, the design of the structure will be incorrect.

What dimensions depend on

Specific parameters of rental: width, height, wall thickness, rounding radius, dependent on the method of manufacturing products.

There are 3 technologies for the production of profiled analogues.

- Hot deformation of semi-finished product.

- Cold deformation of round billets.

- Forming a semifinished product and welding its seams.

Warping blanks

Features of the production technology affect the calibration method, wall thickness and other dimensions of the product.

Hot rolled analogs

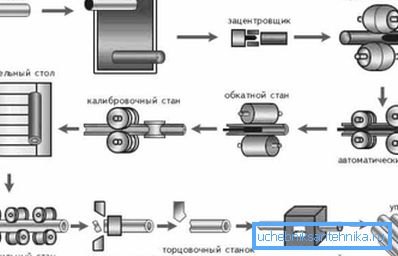

Below is a brief description of the production of such products.

- The semi-finished product in the form of a sleeve (glass) heated for better plasticity is rolled by forming rollers to obtain a blank - a round pipe.

- Then it goes to a molding press, which stamps a square, rectangular or oval product from it.

- Next, the workpiece is cooled, then rolled calibrating rollers.

- Then it is “released” - heated until the formation of the grain and gradually cooled in air. This removes the strain on the crystal lattice of the material.

Note! According to the standards, hot-deformed profile materials cannot have a cross section less than 60 mm. That is, for example, the profile pipe 60 to 30 in this way is not performed.

- According to GOST №8645 / 68, about 20 sizes of rectangular shaped pipes are manufactured, and according to GOST No. 8639/82 - the same number of square analogues.

- The minimum dimensions of the latter are 60? 60 mm, the maximum - 180?

- In rectangular products, the thinnest is the profile pipe 60 by 80, and the thickest one is analog, with a section of 230?

Hot deformation also affects the wall thickness of the material. If the products are manufactured in this way, the features of the technology set the minimum limit of this value to 4 mm and the maximum to 14.

Another important dimension of hot-rolled products is their length. It can be “dimensional” and equal to a certain cut or “unmeasured”, i.e. be within the scope of the cut.

The smallest hot rolled has a length of 4 m, and the longest - 12.5 m.

Cold rolled material

Below is the technology of manufacturing such products.

- Making the semi-finished product, planting a round hole in the washer.

- Making the workpiece, the method of rolling to obtain a round billet.

- Obtaining a profile analogue by compressing the workpiece on the press and rollers.

- The final stage is product calibration.

In this case, the cross-section and wall thickness of the finished product is slightly less than that of hot-rolled counterparts. According to the relevant standard, cold-rolled materials cannot have a section face less than 10 mm and more than 120. That is, the thinnest cold-rolled profile pipe is 10x10, and the most formatted one is 120 × 120.

According to GOST No. 8639/82 there are 17 sizes of similar products, and according to the standard 8645/68 - 16. The wall thickness of cold-formed pipes can be 1/8 mm.

The length of their dimensional segments varies from 4.5 m to 11. Non-dimensional cuts may have a minimum length of 1.5 (profiled tube 10 to 10) and a maximum of 9 m.

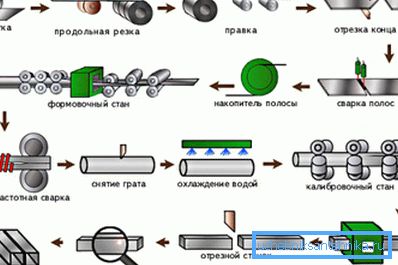

Welded rental

Below is the technology of welded production.

- Creating a strip - dimensional sheet semi-finished product. It is cut from unmeasured steel sheet.

- Forming the billet, bent according to the shape of the cross section of the final product.

- Welding the pipe seam in an inert gas or using induction melting of steel and its welding.

- Calibration of the product by cold rolling. (See also the article Butt-Weld Pipe: Features.)

Note! The physical characteristics of welded materials are almost the same as that of seamless analogues. The joint weakens their strength and rigidity by only 5/10%.

This circumstance is compensated by the possibility to manufacture products with a small wall thickness (1/5 mm), with a wide range of parameters. So, the thinnest element has a face of 1.5–1.5 cm, and the most formatted one is a welded profile tube 30 by 30 cm.

The length of the material is measured or unmeasured. In the first embodiment, the size of the product fits in the length of the measuring segments from 5 m to 9. In the second variant, it is in the overall parameters of the non-dimensional sections that have a length of 1.5 / 9 m.

In addition to square and rectangular materials, with the help of welding they also produce pipes of oval cross section. Their parameters are normalized by State number 8642/68.

According to this standard, the thinnest oval welded profile has a cross section of 16? 10, and the most voluminous - a profile pipe 80 to 40, as well as 90? 32. The wall thickness of such products is 1 / 2.5 mm.

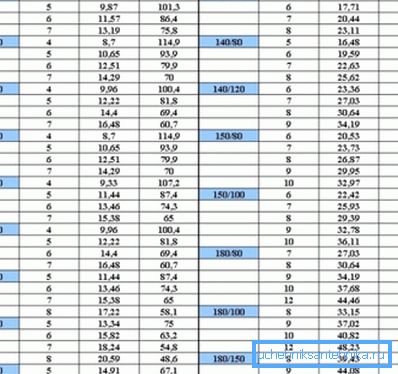

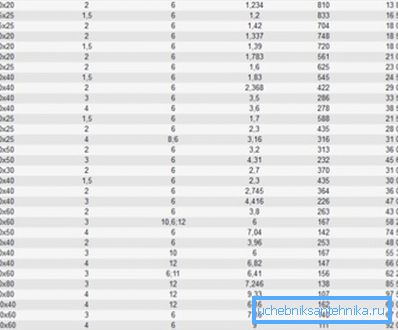

Below is a table of the dimensions of the profile pipes produced by the welding method.

| Sq. section | Rectangular section | Wall thickness mm |

| 1 1.2 1.5 1.8 2 2.5 3 3.5 4 5 5.5 6 7 8 9 10 12 12.5 14 16 | ||

| 15–15 | ? | |

| 20–20 | ? ? ? ? | |

| 25? 25, 30? 30 | 40–20 | ? ? |

| 40? 25 | ? ? ? | |

| 40? 40, 50? 50 | 50? 25, 60? 30, 60? 40 | ? ? ? ? |

| 80–40 | ? ? ? | |

| 60? 60 | ? ? ? ? ? ? ? | |

| 80? 80 | ? ? ? ? ? | |

| 90–90 | 120–80 | ? ? ? ? ? ? ? |

| 100? 100, 120? 120 | 140? 120, 140? 110, 150? 100 | ? ? ? ? ? ? ? ? ? |

| 140? 140, 150? 150 160? 160, 180? 180 | 160? 140, 180? 120, 180? 140, 200? 100 200? 120, 200? 150, 200? 160, 240? 120? ? ? ? ? ? ? ? ? ? | |

| 150? 130, 160? 120, 180? 100 | ? ? ? ? ? ? ? ? ? ? | |

| 200? 200, 220? 220 | 240? 150, 240? 160, 250? 140, 250? 150 260? 130, 260? 140? ? ? ? ? ? ? ? ? | |

| 300 × 100 | ? ? ? ? ? ? ? ? ? ? ? | |

| 250? 250, 300? 300 | 280? 240, 300? 200 | ? ? ? ? ? ? ? ? ? |

Conclusion

If you are going to build a metal framework with your own hands, then you should be clear about what elements are needed for this. Their cross section and wall thickness should be optimal, so that on one side the strength of the structure was sufficient, and on the other, it was not too heavy.

The video in this article will help you to understand the topic in more detail.