Do-it-yourself installation of copper pipes: execution

In this article we will describe how the installation of copper pipes with their own hands and what tools for these purposes may be required. Despite the fact that components from non-ferrous metals are little in demand in the construction of plumbing and heating systems, the topic does not cease to be relevant, as copper pipes of medium and small diameter are used in various fields.

Immediately, we note that the installation of copper is significantly different from working with other types of metal pipes. But before installing the copper pipes, we’ll tell you about the main advantages and disadvantages of this material.

Main characteristics

Many have seen a fun science-based experience using a copper tube and a neodymium magnet. It turns out that the foci, where the magnet in the copper tube moves slowly, is not the only advantage of products made from such colored metal.

Among the advantages of this rental, we note the following:

- resistance to non-ferrous metal to oxidative processes;

- ease of machining due to the softness of the metal;

- ease of installation due to different methods of pipeline assembly;

- environmental safety and zero impact of copper on the characteristics of the transported medium;

- attractive appearance, and therefore the possibility of use in most modern and classic interiors.

However, there is one major drawback due to which copper pipelines are not widespread - this is a high price.

The main methods of installation of copper pipelines

Installation methods of heating or plumbing systems are determined by the characteristics of the pipes used.

Copper is a soft metal, and therefore the traditional methods of joining with threading are relevant only to thick-walled products.

But since the majority of buyers, for reasons of money saving, acquire exactly thin-walled rolled products from non-ferrous metal, we will focus on such installation methods as:

- solder welding;

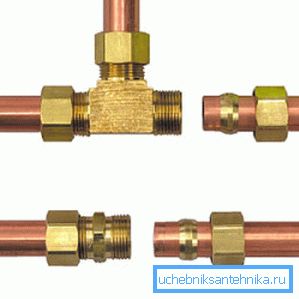

- connection using press fittings;

- spore with collet fittings.

Consider each method in more detail.

Acetylene torch soldering

Soldering can be accomplished through the use of special threadless fittings. In addition, it is possible to solder using a self-made socket. In this case, a special pipe expander is used for the copper pipe.

The pipe expander is a hand tool, the working part of which is inserted into the hole of the pipe. By scrolling the handle around its axis, the walls are flared, and the cross section acquires a larger diameter without compromising the integrity of the wall.

The welding instruction is as follows:

- using a special cutter, cut the pipe to the desired size;

- then use the hopper for copper pipes and remove the outer and inner chamfer from the end;

- after that, we clean the edge of the prepared product using fine-grained emery paper or adhesive tape-bright;

- further, in the same way we clean the inner surface of the fitting;

- the bare end of the pipe and the inner surface of the fitting are covered with a layer of flux or special paste;

- connect all the components together and clamp in a vise;

- we kindle the acetylene torch and heat the joint, gradually passing it along the junction with hard solder;

- after the metal has warmed up, we erase the excess solder with a rag;

- after complete cooling, the resulting unit is ready for operation.

The soldering instruction using a pipe expander is the same and can be applied when it is necessary to build up a pipe without using a connecting fitting.

Important: For greater attractiveness of the welded joint, the soldering area can be sanded with fine-grained emery paper. The color of the metal in the area where the grinding was performed will be slightly lighter, but will darken over time.

Collet connection

The expander for copper pipes can be used not only when carrying out the soldering, but also when performing a collet connection.

Consider the following: how to carry out this type of installation:

- To begin with, we prepare collet for copper pipes and special fittings. Make sure that the harvested components are also made from copper or from alloys containing this non-ferrous metal.

- In the next step, we put on the union nut and the sealing ring on the pipe.

- Then peppered cut we expand and insert the fitting shank into it, after making sure that there are two rubber rings on it, which ensure the tightness of the connection.

- After that you can tighten the nut.

Crimping Press Fitting Application

Important: If you plan to use a special press fitting, you will need a special crimping tool for mounting copper pipes.

The assembly assembly instruction is in many respects similar to the use of collet fittings, but there are some differences. First of all, not a collet fitting with a sealing ring and a cap nut is used, but a similar product, equipped with a soft sleeve, which wraps the pipe around the entire circumference, thus forming a non-separable strong connection.

Installation is as follows:

- the pipe at right angles is cut with a special pruner;

- internal and external chamfer is removed from the cross section;

- the prepared hole is flared;

- the product is put on the shank of the fitting all the way;

- further, with the help of special crimping pliers, the whole structure is fixed.

Important: As already mentioned, the assembly is non-separable, therefore, before installing the fitting, you need to make sure that all dimensions are correctly measured.

Device crimp pliers

Press tongs on the market are represented by two main modifications:

- Hand tool - easy to use, relatively compact, reliable and maintainable devices. Crimping performance depends on the length of the handles. The longer the handle, the easier it is to apply muscular effort and the easier it is to achieve the desired result during installation.

- Electro-driven tool - operation of such devices is much easier and more convenient.

Press tongs, depending on the modification, can be made to work with one diameter or can be universal and have several interchangeable nozzles.

Important: When carrying out installation work, the pliers not only press the edges of the fitting to the surface of the pipe, but also press them in, forming grooves that ensure maximum tightness.

When choosing ticks for single use, you need to give preference to inexpensive, easy and convenient tools.

Pipe bender application

Telling about the tool for copper pipes, it is necessary to note the use of a pipe bender. It is no secret that the plumbing or heating system is not always straight. Depending on the characteristics of the system or the configuration of the room, the pipe should change direction in one way or another.

In order to minimize the use of fittings, the direction of the pipe is changed by bending. The use of specially selected equipment is justified by the fact that the thin walls of a bent pipe will be deformed evenly and will not be creased.

Pipe benders on the market can be equipped with a manual or electric drive. The equipment is characterized by simplicity of the device, and therefore can be assembled by hand.

If the pipe bender is unavailable for one reason or another, a special spring can be used when installing the plumbing or heating system. A spring of the appropriate diameter is placed inside the pipe, and then a bend is gradually made, after which the spring is taken out. Rigid rings of the spring inside are bursting with copper walls and do not allow the folds to form along the inside diameter of the fold.

Conclusion

In this article, we looked at the instructions for self-assembly of plumbing and heating systems using copper components. In addition, we reviewed the main types of tools that can be used for installation work.

Are there any questions that need clarification? In this case, more useful information you can find by watching the video in this article.