Drainpipe: manufacturing materials and installation

When the rainy season comes, the problem of flooding the site and the flow of water from the roof becomes very relevant. The fact is that it is necessary to properly organize the drainage of waste to avoid the penetration of a large amount of moisture under the foundation or plinth. To do this, a special drainpipe is best suited, which is being developed to meet this specification and application.

Materials and properties

First we need to say that these structures are usually created in strict accordance with the project, which is developed taking into account the terrain and type of roof. At the same time, gutters and pipes on the development plan are indicated with an indication of the material of manufacture and methods of fasteners.

Properties

First of all, it is necessary to mention that all products of this type are created from materials that are well tolerated by direct sunlight and do not corrode at constant humidity.

And this applies both to the outer surface of the products, and to the inner.

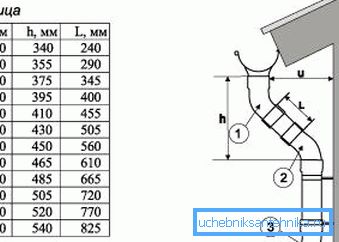

- It is important to note the fact that the diameters of the drain pipes are used very diverse and they depend only on the capacity, which is calculated taking into account the roof area. Therefore, before purchasing materials you need to have a finished project.

- Special attention should be paid to the fact that the marks of the drain pipe and all other structural elements should have a small weight.. The fact is that the whole system is actually mounted on the plumb of the roof and exterior of the building. At the same time, in times of intense rain, the weight of the entire product will be quite large and you should not increase it with a choice of heavy structural elements.

Tip! Sometimes it is much easier to purchase ready-made parts of such a system and assemble it than to create each node or isolation independently. This will help save time and money.

Galvanized

Usually make drainpipes made of galvanized steel. It has a small weight, perfectly tolerates exposure to sunlight and moisture. However, this type of material is quite malleable and allows you to create additional branches or fastening systems.

However, it should be said that the galvanized drainpipe has a relatively short life. The fact is that the system is constantly exposed to a minor mechanical impact as a result of falling into it of debris or small branches. They leave scratches that open the protective coating and become places of rust.

Tip! Quite often, galvanized products are covered with a layer of paint to prevent the appearance of white scurf, which is a product of oxidation. Therefore, it will serve as a kind of protection.

Plastic

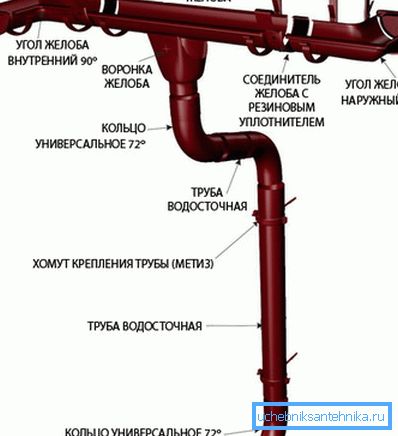

Standard drainpipe plastic pipe looks almost the same as the system of galvanized. Rather, it was created exactly on the same principle, with the difference of the material of manufacture.

It is worth noting that the knee of a plastic drainpipe is flatter, since it does not have stiffeners, which are characteristic of metal systems. In fact, the whole structure is very smooth and has no pronounced internal joints.

It must be said that the price of plastic products is higher than that of metal systems. However, due to the long service life of such a cost can be considered quite justified.

Tip! Designs based on plastic products may have a different color. Therefore, their choice should be focused on the exterior of the building.

Installation

Usually the installation of drainpipes is made in strict accordance with the project. Especially if all wastewater enters the storm sewer system. Therefore, it is worth exploring this plan in detail, especially in the joints of fasteners and areas that create a slope.

Assembly and fixing

- If the work is done by hand, then you should immediately understand the docking system of all elements. At the same time, both plastic and galvanized products are approximately the same. They are simply inserted into each other.

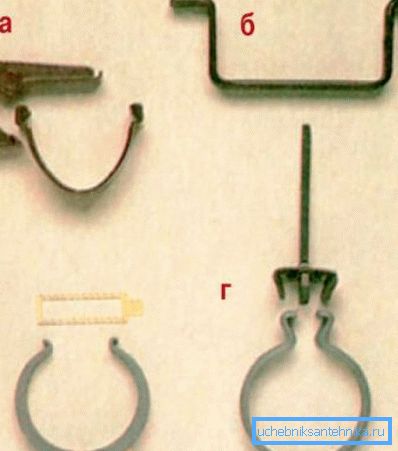

- Standard mounting of drainpipes to the wall is made using special clamps, which are fixed on the wall with impact dowels. Some craftsmen try to choose such elements with rubber pads to reduce the mechanical effect on the material.

- Chutes are mounted using separate elements, some of which can be fixed on the edge of the roof. In this case, the installation manual strongly recommends that you check in advance the compatibility of such structures with the material used for the manufacture of the roof.

Tip! The density of the connection hardware and pipes should be maximized. Otherwise, under the influence of wind, the system will loosen and friction may occur.

Insulation and heating

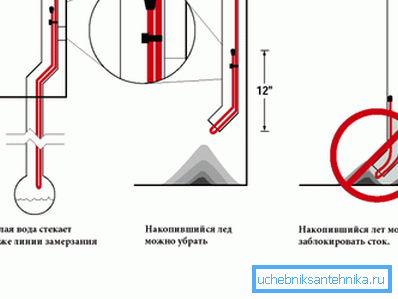

Usually heating the drainpipes do not. Their main purpose is to divert rainwater, and this weather happens in a relatively warm season. By the onset of cold weather, these lines remain dry and do not form ice jams. (See also the article Heating the pipes with a heating cable: features.)

Some masters prefer to install a kind of heating drainpipes using electric mats or wires. They are used in the cold season and allow you to melt not only the ice in the system, but also the snow on the roof, which will ease the pressure on the structure.

Tip! Galvanized iron systems are sometimes heated with a blowtorch or bonfire, which is bred under the edge of the drain. However, resorting to this method is necessary only as a last resort.

Conclusion

After thoroughly studying the video in this article, you can learn more about drainage systems and installation. In this case, based on the text above, it is necessary to conclude that this work is quite simple and does not require the presence of certain skills. However, before starting the installation, you need to acquire a quality-made project.