Drill pipes: features and application

Pipes in modern life are used everywhere, and in some industries it is simply impossible to do without them. However, there are areas of their application that need similar products of specific design. That is why drill pipes are very easy to distinguish from ordinary materials of this type.

Design features and specifications

First we need to say that such products are used only for work related to the drilling of holes in the ground. The use of these materials in other areas is considered wasteful and impractical because their price is quite high. At the same time, it does not make sense to use the life cycle for other needs of the product, which simply does not make sense, because after working out they usually go only for scrap metal.

Species

First of all, it is worth mentioning the weighted drill pipe, since they can withstand high loads, which affect not only vertically, but along the entire length of the product.

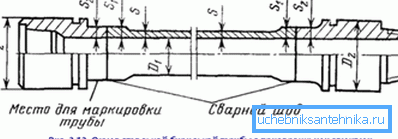

- This material has high strength and has thick walls.. It is important to mention that such a drill pipe is manufactured in accordance with GOST 7909 56 and that even the most insignificant parameters specified in it are not violated.

- It should be noted that these types of products at their ends have a special thread, which has a strictly defined step and section type.. It is also important to mention that such products are made of the appropriate length, which is also displayed in GOST.

- Special attention should be paid to the fact that the leading drill pipes are fixed with each other not only by means of a threaded connection, but also with the help of special couplings. Such devices are specifically designed for the drilling industry, and they have a specific design.

- Also in this area light alloy drill pipes are often used.. They are excellent help to reduce the overall weight of the system, while removing the additional load created by them.

- When doing such work, it is necessary to produce water drainage, create a casing, and establish a connection to the water supply system.. Various types of pipes are also used for this, but the installation instructions do not insist on the presence of certain properties of them or of a special alloy of manufacture.

Tip! To save money, professional craftsmen recommend making such products to order from special companies. If you constantly purchase branded materials of this type, the cost of work will increase dramatically.

Special features

- First of all, it is necessary to mention that almost all drill weighted pipes according to GOST are made of metal that is susceptible to corrosion. This is done to give them certain properties and reduce the cost of consumables, which sometimes such products are. Therefore, these pipes are covered with a special protective layer, as which colorless varnish is often used.

- Separate protection supplied thread. It is abundantly greased with a thick layer of fat or a special compound. If the drilling process is done by hand, then after work you must update this coverage.

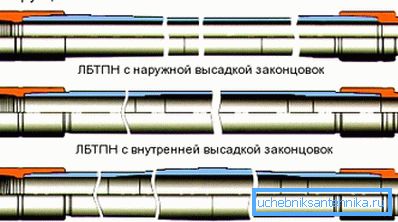

- It should be noted that some principles of drilling holes in the ground suggest the presence of specific pipes with a special design. They can have flaring, mounted nipples or specific locks on additional threads. Also, some types of such structures have a different moment of screwing the drill pipe, which depends on the process or type of installation used.

Tip! It is believed that for each type of soil it is necessary to use not only a special drill, but also a type of pipe that would be designed for specific loads. However, in most cases, masters use universal products.

Optional equipment

When it is necessary to purchase pipes of this type, it is mandatory to add additional elements to them, without which it is simply impossible to perform work or maintenance. At the same time, elements such as drill pipe subs or wipers should be selected according to the type of installation itself and casing strings.

Locks

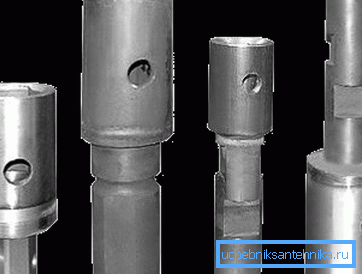

Separately, this device is purchased only in the case when on the pipes themselves there is no corresponding cutting for the connection. They are also excluded from the list of purchases, if the ends have welded clamps or a fitting thread for a pipe coupling.

The fact is that the locks for drill pipes serve as a kind of connecting elements that connect all sections into a column. In this case, most often they are made separately and therefore their choice should be approached very carefully.

Tip! Professional masters recommend purchasing all the elements necessary for the work of such works from one manufacturer. So you can avoid problems associated with incompatibility of equipment.

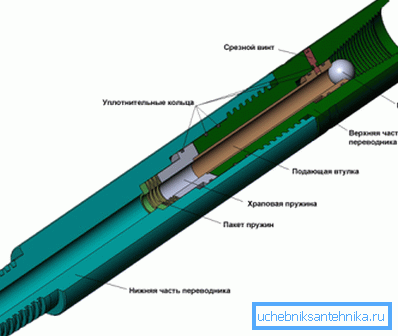

Translators

In fact, this element performs the same functions as the lock. However, it allows the most rigid transfer of torque, even with a change in the diameter of the material used.

Recently, a safe drill sub has become popular. It gives the opportunity to separate part of the column, if the drill pereklinilo or an accident occurred. Therefore, it is installed between the first pipe and the rest of the column.

There are also conventional connecting subs, which are used in all sections of pipes. In some types of geological exploration, they are much more popular than other elements with similar functions.

Tip! Most craftsmen prefer to order such parts separately. However, many of them have their own personal understanding of the appearance and design of these elements of the system.

Obtirators

Typical wipers for drill pipes have the form of two flat rings of metal, between which rubber or polyurethane gasket is clamped. The diameter of the hole in the ring should be slightly larger than that of the pipe, but the seal usually protrudes several millimeters.

The purpose of such a product is to ensure that when removing the columns from the hole there is no dirt or earth left on it. Also, the width of the metal rings is chosen so that it overlaps the well, preventing debris from entering there.

Tip! There is simply a huge variety of various additional elements used in this type of work. However, all of them need to be selected in accordance with the technological process, which is designed for specific equipment and a well.

Conclusion

After reviewing the video in this article, you can examine in detail the types of pipes that are used in drilling. In this case, special attention should be paid to their design and connection to each other. (See also the article How to make sewage in the house: features.)

Also based on the text proposed above, it is necessary to conclude that drill pipes are manufactured according to GOST. Any deviation from it is a marriage, and quality control is carried out not by batch, but by unit of production.