Ductile iron pipes - features and applications

The abbreviation of pig-iron pipes of the ЧSHG is defined as “high-strength nodular graphite”. Most people associate such pipes with sewage systems, however, in reality, the scope of their use is not limited to one sewage system. Next, we take a closer look at the features of such pipes and consider for what purpose they are used.

General information

Cast iron, as it is known, differs from steel by a higher carbon content. To get steel, cast iron is sent to steel-making units where air is supplied. As a result, oxygen binds carbon to carbon dioxide.

In this way, steel is obtained which has higher performance characteristics than cast iron.

In particular, the following advantages can be singled out:

- Increased strength to stress;

- Viscosity and plasticity.

However, steel has one rather serious disadvantage - susceptibility to corrosion, which is unacceptable for sewer pipes. For this reason, steel pipes in sewer networks do not apply.

To increase the resistance of steel to corrosion, scientists have come up with the addition of chromium, vanadium and titanium alloys to it. However, this led to a significant increase in the cost of material. Therefore, further work began to be conducted in a different direction - finding a way to control the shape of graphite contained in gray iron.

In 1943, an American scientist, Kate Millis, was able to get nodular graphite instead of lamellar in cast iron. This modification was successful due to the addition of a small amount of magnesium to the molten iron.

Thus, cast iron pipes, which have good strength and at the same time resistant to corrosion, appeared.

Properties of VChGG pipes

So, the main advantage of the iron of the high-speed iron group is high strength in combination with good casting properties.

According to GOST 7293-85 it is stated that such pipes should have the following advantages:

- High ductility;

- Minor sensitivity to the appearance of voltage concentrators;

- Resistance to cyclic loads;

- Ease of machining;

- High heat resistance;

- Resistant to aggressive environments;

- Low friction coefficient;

- Low price.

With regard to the casting characteristics, the chelate class has:

- Good fluidity;

- Small shrinkage ratio;

- Slight tendency to form hot cracks.

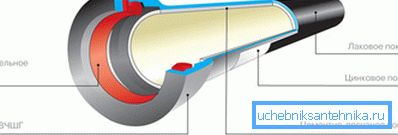

It should be noted that the outer part of the products is covered with a double protective coating:

- Zinc;

- Bituminous varnish.

This coating increases the durability of products. However, if the pipeline fits into the soil containing aggressive chemical elements, special coatings can be applied.

Application area

Thanks to all of the above qualities, high-frequency iron pipes are used for a variety of purposes, among which are the following applications:

| Oil and gas production | Pipelines are used to transport products extracted from wells to separation plants. |

| Water supply | For these purposes, use special pressure pipes. They are widely used for industrial desalination plants, as well as for water supply (outdoor). |

| Sewage systems | Cast iron pipes for sewage have lost their popularity, but, nevertheless, they continue to be used in our country. |

| Heat supply | In networks where the temperature does not exceed 120 degrees. |

Tip! Despite all the advantages of the cast-iron pipeline, it is more expedient to use plastic pipes, as they weigh much less and can be mounted by hand.

Kinds

First of all, VChShG pipes differ in the method of connection:

- Under the welded joint (cast iron is perfectly cooked with special electrodes);

- Under the socket connection.

Note! The installation instructions for a pipe with a socket connection imply a chamfer at one end of the pipe. If it is cut, then the chamfer must be made independently to ensure the tightness of the joint.

In addition, different pipe properties are required in different applications, which accounts for their diversity.

Below we consider their main types:

- Pressure - made according to GOST 9583 75. Depending on the wall thickness, they are divided into three classes:

- LA;

- BUT;

- B.

The most common is the pressure pipe of the high-frequency graph of 150 mm, which is used for laying pipelines.

- With flange connection - these products are produced by the Russian company “Free Falcon”. The flange connection provides a simple and reliable collapsible installation of the pipeline.

- With cement-sand coating - have higher hygienic properties. Therefore, they are used in the device of drinking water for drinking water. It should be noted that the ductile iron pipe with the CPP is not subject to slagging and is protected from corrosion. This allows it to preserve the quality of drinking water, which is regulated by the SNiP.

Tip! As a result of the existing confusion in the documentation, when choosing products, it is better to get acquainted with the current price list of the manufacturer, rather than relying on the assortment indicated by the GOST.

Here, perhaps, are all the main features and types of pipes of the Cheka.

Conclusion

VChGH pipes have many unique properties. Therefore, despite the appearance on the market of modern materials, they are still in demand in various applications. This is largely facilitated by the variety of products of the high-frequency iron cladding group, which may have certain properties necessary in different operating conditions.

From the video in this article, you can get more information on this topic.