Electric cable for heating a water pipe: selection and

The owners of private houses usually arrange an autonomous water supply system, the source of which is a well or a well. Fluid delivery is carried out using conductive elements of a specific diameter. For reliable operation at low temperatures, a heating cable for water supply inside the pipe or outside is very often installed.

The advantages of using heating

The construction of electrical systems is an integral part of communication networks in regions with very cold climates, especially if the line runs at a shallow depth. The advantages of using wires are obvious.

The following are the most basic of them:

- The price of the laid cable is low, so it is possible to organize an inexpensive pipe heating system.

- The outer surface of the pipelines will not be covered with ice, which will positively affect their operational period.

- When laying the elements, excessive penetration into the ground cover can be avoided..

- Cable installation provides the ability to maintain a stable temperature during the winter period..

- If necessary, you can lay a heating cable for the water supply inside the pipe yourself, saving some amount of money.

Note! Although this system has many positive qualities, it has one drawback. During operation, electricity is consumed, so costs in winter usually increase. The final amount depends on the power of the core.

Varieties of basic elements

Modern water networks use different types of cable. Usually there are resistive and self-regulating products. They operate on the same principle, that is, they convert electricity directly into thermal energy. However, in terms of the structure of the device are very different.

Resistive cable

In this case, the element is a tubular electric heater having a thick core in the center, which is covered with an insulating braid. A good level of elasticity allows installation in pipelines of almost any configuration. The lack of control of thermal efficiency has a bad effect on efficiency.

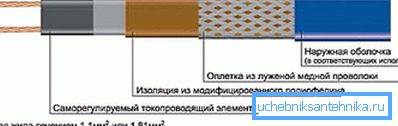

Self-regulating analog

In this embodiment, instead of the heating core, a ceramic matrix is installed, which can change the resistance, taking into account the ambient temperature. Thanks to the thermostat, it is possible to carry out the adjustment automatically, so that the excess energy is not consumed. Products of this type are characterized by increased resistance to voltage surges.

Components of the system

In fact, the complete set of heating networks may vary significantly depending on the technical specifications. However, most often in the system there are certain elements and nodes.

You can get acquainted with them if you look at the list below.

- As the component conducting the electric current, the cable itself is used directly of a suitable type.

- Magnetic starters, RCDs and other wiring accessories allow the system to start.

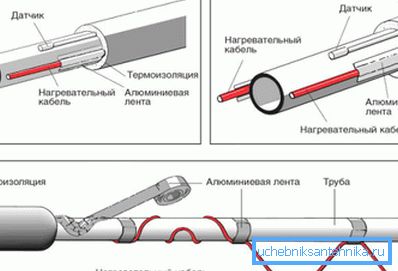

- Aluminum tape with a self-adhesive side is usually used to create insulation.

- Thermal insulation is carried out to reduce heat losses, resulting in saved financial resources.

- The thermostat is mainly installed if a resistive cable is used.

Reference! The last component may not be used for self-regulating analogues, since when connected to a power system, the heating level is set automatically.

About the work

At the design stage, it is necessary to make preliminary calculations, calculating the length and power of the cable that will be used for heating purposes. Many factors should be taken into account, among which an important role is played: climatic conditions, depth and diameter of pipelines, length of the pipeline, as well as the level of thermal insulation.

When laying is carried out from the outside, the cable is pressed against the water pipe and secured with aluminum tape. In this case, the wire can be arranged in a spiral, wave or along. After installation, the entire structure is insulated. In especially important places, thermal sensors are installed.

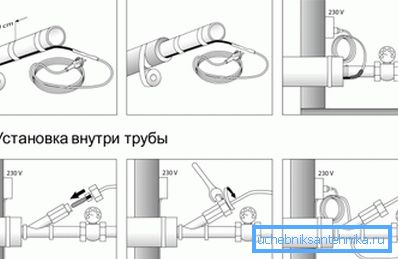

The internal cable laying method is also actively used. In this case, it is placed directly in the pipe. The installation technology with this option becomes more complicated, and the system efficiency increases. This method of laying is used to ensure reliable operation of important components.

Electrical energy is consumed more economically when the cable is inside, because during operation, the fluid is heated directly, and not the pipelines. You can arrange the cable in this way even after working on the installation of water supply when the trenches are buried.

If the installation is carried out in winter, the cable used may become brittle. To avoid damage, it is sometimes admitted to the network. Products after warming gains the necessary flexibility, making installation much easier.

As a conclusion

The instruction manual is presented so that the residents of the cold regions of the country can arrange the heating of water pipes with a cable with their own hands, without spending money on attracting specialists. Of particular importance should be given to preliminary calculations, which will help to choose the best option. Thematic video in this article will help to better understand the topic.