Electrotechnical pipes - properties and application

Laying electrical wiring requires not only knowledge and tools, but also certain materials. In addition, it is important to properly distribute the accumulation of wires among themselves so that it is convenient to work with them later.

You can install it in such a way that it is not visible from the outside (hidden option) or you have constant access to it (open method).

Types of electrical pipes

The first option is easier to install, easy to maintain and reliable. The second requires the use of special boxes, pipes, metallic flexible wires, structural voids.

According to the rules of labor protection and fire safety, it is recommended to run electrical wiring in special electrical products, for example, in pipes.

They are produced in various types and use different materials for this, they have proved their usefulness in construction and other industries. The price of products allows you to use it without restrictions.

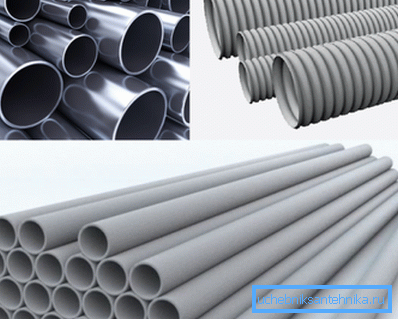

Plastic - PVC and HDPE

No matter what method of laying you decide to use, you can use the following pipes of these materials:

- corrugated;

- smooth tough;

- reinforced flexible, which allow to protect the working cables of various equipment;

- double walls for installation in water or soil, when it is necessary to lay a power cable of large cross section and fiber optic network (only HDPE).

The general properties of electrical structures can also be attributed to their resistance to mechanical damage, insulating qualities, resistance to different temperature conditions (from –20? С to + 90? С).

Usually they are of two types:

- with probe for cable pulling;

- without probe.

Electrical PVC pipe is made of polyvinyl chloride, using the method of continuous extrusion. This material has fire-resistant properties, dimensions: O16-50 mm, length - 3 m.

The advantages include:

- ability to resist mechanical damage;

- sufficient stiffness;

- small linear expansion coefficient.

Tip: PVC pipes are best PVC proven when laying electrical wiring under the concrete.

Rigid smooth products are used as additional mechanical protection and cable insulation. You can use it to open the wiring on the walls and ceiling, made of their low-combustible building materials.

The choice of such products on the market is very large:

- tough smooth;

- reinforced;

- corrugated;

- smooth rigid, for the manufacture of which used self-extinguishing polyvinyl chloride.

PND Electrical Pipe is able to withstand chemicals. But, the material does not have sufficient shock resistance, and it also has a high permeability.

Such pipelines are used for:

- water supply;

- electrical wiring;

- laying insulating cable in the soil;

- household needs.

Installation

Laying your own hands should be made, taking into account the qualities that are inherent in PVC. For example, its good frost resistance allows installation even at -30? С.

Tip: pay attention to the joints that need to be sealed so that they do not get dust, oils, technical emulsions, as well as no condensation.

To remove the accumulated moisture, pipes should be laid with a bias towards the draw boxes. If you are installing in the foundation or between the communications of the base of the building, guide the gasket strictly horizontally.

It is advisable to keep laying the shortest way, the main thing is to ensure that there is no risk of damage to the highway.

Tip: when laying the cable in rigid PVC pipes at a depth below 2 m, to protect the latter, a concrete layer with a thickness of 800-1000 mm is needed.

Products must serve as a protective barrier for the electrical cable from various mechanical effects in different ways of laying the wiring.

Therefore, it is necessary to adhere to the established requirements of SNiP, fire prevention rules and installation regulations for electrical installations:

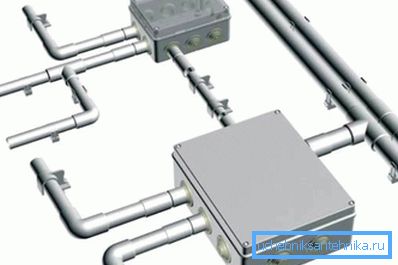

- Inside and outside the premises, the installation is carried out on the supporting bases of electrical installations.

- The instruction allows to work in the temperature range from -5? С to +60? С, operation is allowed in the following mode - from -25? С to +60? С.

- The open version allows installation inside and outside the premises on the basis of any degree of flammability.

- Hidden installation in the walls, ceiling and floor is possible only on the base, made of non-combustible materials. Also, pipe laying can be carried out in a concrete massif.

Steel

Electrical steel pipe is able to protect wires and cables from mechanical stress. Usually it is used in the construction of objects made of wood and for the equipment of premises to which high requirements for fire safety are imposed.

The range of such products is large, below are the main types of threaded steel electrical pipes, where the thread is cut from one end and the coupling for the other is installed:

| Varnished | It has a black protective coating made by dust spraying. This allows the material to resist corrosion. |

| Galvanized | Produced by hot galvanizing. The thickness of the zinc layer is 14-100 mm. |

Non-lacquered steel electrical piping is also produced. Usually the length of any model is 3 m.

PVC corrugated

Electrotechnical corrugated pipes according to GOST are designed to protect electrical, telephone and television cables. Due to the ease of bending in any direction, can be used for electrical work in suspended ceilings and other structures, where there is no possibility of installing rigid boxes and systems. Products used for open and hidden wiring.

The operation of corrugated electrical components exceeds half a century. With their help, it is possible to ensure reliable security and easy installation of wiring systems. Products may have a different diameter - 16-63 mm and wall thickness.

In the latter case, this affects the degree of load that they can withstand. The material is self-extinguishing plastic-PVC, which will not allow the fire to spread along the structure in case of fire.

Conclusion

Convenient electrical systems for laying cables and wires greatly facilitated the work of laying and wiring. In addition, they have become for them an additional protective barrier.

In practice, used pipes made of steel, HDPE and PVC, the latter can also be corrugated, which increases their capabilities.

The video in this article will help you find additional information on this topic.