External water supply and sanitation networks: installation

Each dwelling should be equipped with a water supply and sewage system. This is one of the most important conditions for a comfortable living person. In order for these engineering structures to function, they must be connected to external highways. It is good if there is a city sewer and running water near the house. You can easily connect and use.

Let's look at the features of the installation in order:

- Before starting work, it is necessary to draft a future highway. Set soil type and groundwater level. Find out the level of soil freezing - it is different for each region. Calculate the flow and drainage of water per day to determine the diameter of the pipe. Based on all calculations, the necessary equipment will be selected.

- External highways should lie below the level of soil freezing by 50 cm. If this condition is not feasible, the pipeline will have to be insulated, which will lead to additional costs.

- When the pipeline has to go through any section that cannot be dug, a puncture is made in the ground. It is performed using various tools. At home it can be a drill, shovel, scrap and other devices. In large-scale construction, for example, under roads, punctures are performed using special equipment.

- In the case of intersection of water pipes and sewage, at the intersection point, metal sleeves are installed. The length of the liner in the sandy soil is 10 m at each side of the intersection point of the pipes. In clay soil and black soil the length of the sleeve is 5 m.

- The water supply system at the intersection is placed 40 cm above the sewer.

- With parallel passage of pipes, the distance between them is maintained at least 1.5 m. The water mains are placed above the sewage system, also 40 cm.

- The water supply to the residential premises should be located at a distance of 1.5 m from the gas pipeline and sewage system.

External water network

Before starting work, it is necessary to dig a trench from the source of water intake to entering the room. Works are performed according to the prepared project. The depth of the trench is from 1.5 to 2.5 m and below the freezing level by 50 cm. The bottom of the trench is leveled and covered with a pillow of sand and gravel. Then this pillow is rammed, and prims are dug out at the pipe joints. For installation used pipes made of various materials. Now, because of the durability and ease of installation, plastic pipes are widely popular. The diameter is calculated by the length of the water supply and the volume of water consumed. It is better to take a little bit with the stock:

- If the length reaches 10 m, it is enough to install from a 25 mm pipe.

- If the length reaches 30 m, then a pipe with a diameter of 32 mm is taken for installation.

- If the length is more than 30 m, it is necessary to use a pipe with a diameter of 38 mm.

Connection of pipes is made depending on their material. This may be welding, brazing, coupling connection, etc. Installation of water supply starts from the point of water intake to the premises. If necessary, stop valves are placed on the pipeline. An inspection well is being built at the place of installation of the reinforcement. At the lowest point of the pipeline, a drain valve is installed for emergency discharge of water and a manhole. After installation perform hydraulic test tracks.

The line is filled for 2 hours with water without pressure. After this time has elapsed, pressure is applied and held for about half an hour. All connections are checked. After successful testing, if required, the pipeline is insulated with special materials. The trench is first filled with soft soil or sand with gravel, so as not to damage the pipe with solid pieces of earth. Then there is a complete backfilling of the trench.

Outdoor sewer network

The installation of the external sewage network also starts from digging a flat trench from the cesspool to entering the premises and is 50 cm below ground freezing. If, due to the location of the area, you cannot dig a flat trench, a well is installed at the turning point. The bottom of the pit is leveled and covered with a sand cushion of about 10 cm. In large sewer networks, a well for inspection is installed every 10–12 m.

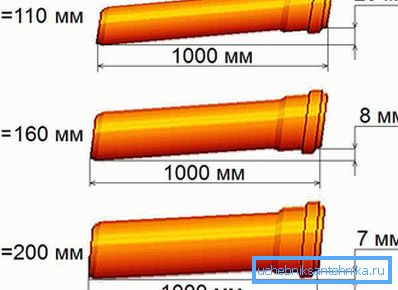

In everyday life, pipes for installation are made of cast iron or PVC. The diameter is selected according to the volume of wastewater. For a washbasin and a bathroom, a diameter of 50 mm is sufficient. If you connect the toilet and other water consumption devices, installation must be performed from a pipe with a diameter of 110? 160 mm. Pipe for outdoor sewage currently prefer to install PVC. It differs from internal pipes in orange.

The installation of the system starts from the sump to the room. When laying the pipeline, it is imperative to withstand the slope, since the wastewater will move by gravity. The slope is maintained within 2–3 degrees from the starting point to the sump, which is approximately 2 cm per 1 meter of sewage pipe. It is impossible to overestimate the slope, since liquid drains will quickly flow out, and solid? stay in the pipes. It is also impossible to lower a slope. Otherwise, all solid accumulations will not be able to move along the pipe with the water. Installation of PVC pipes is performed by joints, into the groove of which a rubber ring is inserted. In wells, a tee is installed on the pipeline with a window for inspection.

At the end of the work, the line is tested by simply draining the water. Connections are checked. With a positive result, if required, the pipe is insulated. The finished sewer network is filled with sand and then the rest of the soil. This performance can be considered complete.