Finned tubes: features and method of manufacture

These pipes occupy a separate niche among materials of this type and are widely used in everyday life and in production. However, it should immediately be said that the field of application of structures based on them is very specific and very limited. The fact is that finned tubes are used for heat exchangers, since their shape is specially designed to increase the area of the product, which leads to improved cooling or heating.

Design features and manufacturing process

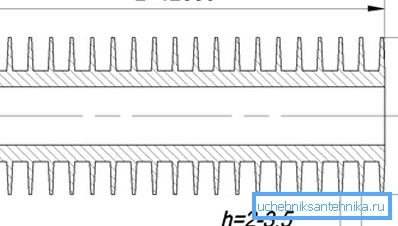

To begin with, it is necessary to say that these types of pipes have almost the same construction, regardless of the material from which they are made. However, on closer examination, certain differences can be found, depending on the application. They are in the form of petals and may have a different coefficient of finning tubes.

Manufacturing

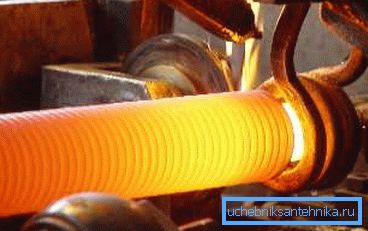

This process depends on the brand of pipes and is sometimes produced using various technologies. Therefore, it is worth getting acquainted with the most popular option, since it is the most versatile and requires the use of several operations.

Given this, it will be quite problematic to produce such finning of pipes with your own hands.

- First you need to put on the selected material groove in the form of a snake over the entire area. It is best to use a special machine in the manner of turning and a special cutter.

- After that, a copper strip, which is practically pressed inward, begins to be placed in the grooves made under stretch. Some machines at the same time use additional heating, if their instructions for the manufacture of these products it provides.

- After the product is ready it is covered with a layer of zinc. This will protect against oxidation, give additional strength and significantly increase the service life.

Tip! There are methods for self-production of such materials, without the high costs and complexity of the process. However, the effectiveness of such structures leaves much to be desired.

Species

- Finned copper pipe or products from the same type of metal is considered the most popular.. It conducts temperature well and can serve both during heating and cooling.

- Bimetallic products are gaining popularity only recently. The fact is that they consist of two types of metal, different in their properties. Therefore, they not only carry out heat transfer well, but can maintain a certain mode for a long time.

- Given these features, bimetallic systems are most often used for heating.. However, these structures and combinations of various materials are still being studied.

- It is worth noting that the remaining differences between different types of pipes are only in the form of ribs and the distance between them.. However, this parameter is very dependent on the diameter or scope.

Tip! Each type of such pipes is used in strictly defined products for which they were developed in accordance with the project. Therefore, today you can find completely unique designs of this plan.

Application area

Most often, these pipes are used to heat various liquids. To do this, they are influenced by fire, and the incoming water immediately starts to pick up the temperature. It should be noted that the price of this method is quite high, but the efficiency exceeds 50% when using conventional pipes. (See also the article Pipes for sewage: features.)

It should be noted that the heating rate in such systems is very high, especially if copper products are used. Therefore, they are used in gas columns. Also, such constructions give off heat very well, which allows pumping hot water through them to heat the room. (See also the article Single-pipe heating system: features.)

As cooling systems, such products are also suitable. However, their effectiveness is several times less and therefore they need additional stimulation.

Tip! Virtually any area that requires organizing a rapid heat exchange between the medium inside the tubes and the surrounding fins will use this material. However, it is necessary to choose the right type of such design in order to increase efficiency.

Conclusion

After reading the video in this article, you can study this type of material in detail and evaluate its properties in more detail. Also based on the text proposed above, it is necessary to conclude that the process of manufacturing such pipes is quite complicated and sometimes it is easier to purchase an already finished product.