Fireplace tube: 6 secrets to a good choice

Pipes for stoves and fireplaces must meet a set of certain criteria if you want them to fully cope with their task of removing carbon monoxide gases from the premises. Not only your health, but also your life depends on the quality of work of such constructions. Therefore, treat all subsequent recommendations with the utmost attention.

Make a choice

To equip your own fireplace chimney best help you the following secrets.

Secret 1st: the refusal of bricks

Asbestos-cement and plastic products are not suitable for the specified purpose at all. But the brick for a long time remained almost the only possible solution to create a suitable chimney, since the price of stainless steel was much higher.

But now, when the cost of building materials has risen and equaled with steel, all the disadvantages of the brick construction of the pipe have become more noticeable:

- Moisture absorption. Even ceramic bricks have enough pores to collect moisture in themselves.

- Cracking. Over time, cracks appear on the walls of brick chimneys, which leads to disruption of their work and, as a consequence, complete destruction.

- The difficulty of mounting their own hands. It is required to possess at least initial skills of the bricklayer.

- Surface roughness. This, though insignificant, but still an additional obstacle to smoke, because of which it is necessary to increase the size of the section.

- Big weight. It is a tangible additional load on the entire building.

- Volumetric dimensions. Takes up too much storage space.

- The need for a separate foundation. Additional costs and requirements for the construction of the house.

- Impossibility of combination with highly efficient boilers, in which the combustion products have a lower temperature.

So, we come to the conclusion that it is more rational and practical to use stainless steel as a material for a chimney pipe, products from which are deprived of all the aforementioned drawbacks.

Secret 2nd: sandwich construction

A very important condition of any chimney is the sufficient force of the thrust carried out, which depends on the thermal conductivity of the product and its size. We will talk about the size and shape of the section a little later, but to increase the thermal insulation of the metal, the “sandwich” technology is used, which consists in the presence of a pipe of three layers:

| Layer number | Material | Purpose |

| one | Acid-resistant heat-resistant stainless steel | Inner casing for accepting exposure to flue gases and other possible emissions |

| 2 | Mineral wool | Lowers the thermal conductivity of iron, which provides it with rapid heating and, as a result, strong traction |

| 3 | Larger galvanized pipe | Protects insulation material from precipitation, mechanical damage and other hazards. |

Tip: in order to save, you can use cheaper material as the outer shell. The main thing that he was able to adequately protect the insulation from the environment.

Secret of the 3rd: choosing the right form

Another important factor in the formation of acceptable traction is a form of the inner part, of which there can be only two variants:

| Section shape | Special features |

| Circle, oval | Air masses pass with little or no resistance. |

| Square, Rectangle | Mini-twists and secondary air streams are formed in the corners. |

This again speaks in favor of abandoning the brick construction, which is very problematic to lay out in the form of a circle.

The secret of the 4th: the correct size

The height and diameter of the chimney for the fireplace are also of great importance in the formation of thrust. For example, the longer the product, the stronger the air flow. But installing a twenty-meter giant above a one-story house is problematic, expensive and dangerous. Therefore it is necessary to adhere to the following optimal sizes:

| Type of fireplace | Chimney section, mm | Minimum pipe height, m | Permissible deviation from the vertical direction |

| With cast iron insert | 180-250 | four | Not more than 60 degrees |

| Open | 200-300 | five | Not more than 30 degrees |

Secret 5th: fire safety

Do not forget that any part of your fireplace is a fire hazard, and in this case the chimney is no exception. Therefore, it is necessary to observe some rules of its location, so as not to expose your loved ones to danger.

Instruction:

- Between the wooden elements of the roof and the inside of the pipe should lie a distance of more than twenty-five centimeters.

- Combustible materials located nearby are to be refractory insulated.

Tip: if the jumble of additional fire-resistant materials threatens a violation of the overall design, you can use flame retardants instead. Processing such substances will not affect the appearance of your home.

Secret 6th: technical documentation

If you do not want to keep you secrets in the installation and selection of a suitable chimney for your fireplace or stove, then read the following documents containing detailed information on all the necessary requirements and conditions:

- SNiP 41-01-2003;

- GOST 9817-95;

- Airbag 252-98.

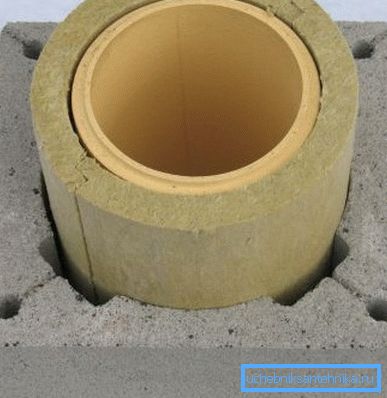

Ceramic chimneys

An interesting achievement of modern technology was the appearance of ceramic chimneys. They are not widely spread due to their high cost and long delivery times, so we did not consider them as an alternative to stainless steel.

But the technical performance of ceramics is much higher, which is characterized by the following advantages:

- Simplicity and high speed of installation work. You only need to assemble the finished blocks into a single structure.

- High heat capacity. The design still keeps warm for a long time after stopping the operation of the fireplace.

- Long operational life, which ranges from 30 to 120 years.

- A wide range of block components, allows you to assemble a suitable design for any fireplace.

- The presence of a technical hole for cleaning the chimney.

- High heat resistance. Withstands up to +1000 degrees Celsius.

- Excellent strength properties in relation to mechanical and temperature effects.

- Absolute smoothness of the inner surface. Due to this, traction is improved, there is no condensate loss, cleaning work is simplified.

Conclusion

If you do not want to smell the smoke when working your fireplace, have the risk of poisoning or fire, then take care to observe all the rules for the selection and installation of its chimney.

To date, the most rational option is to use stainless steel pipes for this purpose, since brick structures are much inferior in quality, and ceramic ones are significantly superior in price. What should be all the other parameters of the required product described above. (See also the article The pipe for the stove: features.)

The video in this article will provide you with additional information relevant to the materials presented. Equip your fireplace correctly.