Fitting for plastic pipes - an overview of the main options

Despite the fact that metal-plastic pipes can be bent without any damage, sometimes they need to be mated with the help of special connecting elements, which are called fittings. With their help, you can connect the pipes to each other, as well as with other elements of the system: meters, filters, valves and other nodes that can be included in the system.

Connection requirements

Regardless of which type of fitting will be used, they all must meet several important requirements:

| Reliability | The connection of metal-plastic pipes with fittings must be durable, since it is in these places that the most problems arise during operation. It is very important to comply with all technology requirements, since leaks are most often the result of improper installation. |

| Simplicity | The more time-consuming process of connection, the greater the likelihood of marriage, we consider only those options that can work with at home without compromising durability and quality of connections. Choose one option or another is necessary, based on the characteristics of your system. |

| Reasonable cost | The price of some modern options is quite high, so this factor should also not be overlooked, especially if you need a large number of fasteners, since this part of the costs can be a significant part of the total costs. |

| Pipe fitting | It is very important to choose fittings that ideally match the diameter of your pipe, this is due to the fact that the wall thickness of different manufacturers may vary. Some manufacturers of pipes produce and components, this is an ideal option, guaranteeing high quality work |

Types of products and their differences

There are several options for connecting nodes on the market; we will look at the three most popular and popular ones that are most often used by both professionals and those who do their own hands (see also the article Fittings for plastic pipes and their types).

Threaded Fittings

This type of compound is also called compression, it is quite widespread for the following reasons:

- A very simple process of assembling the system, since no special tools and equipment are needed, one rozhkovy key of the appropriate size is enough.

- The ability to use each fitting is not one, but several times is also a big advantage. The main thing is to carefully disassemble all the connections in order not to damage or disrupt the thread.

The disadvantages include the following factors:

- The need to periodically check and tighten all connections, this operation should be carried out at least once a year.

- Due to the need to control such mates can not be used in floor heating systems and closed cavities.

Instructions for the work is as follows:

- Pipes are cut into pieces of the desired length.

- A nut and a ring are put on the pipe.

Note! The cut must be smooth, and its edge is treated with either a special device or a file, this ensures reliable connections.

- Further, all nodes are carefully combined, and the nut is tightened, it is important that the elements go along the thread. The knot is tightened to the characteristic slight crackle, do not be too hard to be zealous, because you can damage the pipe.

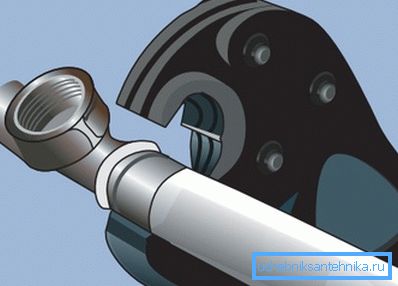

Press fittings

Connection of metal-plastic pipes with press fittings has the following features:

- High strength of all joints, due to which they can be used both in closed cavities and in floor heating systems.

- Easy installation and high performance.

- It should be noted that to work with this group of products you will need a special tool for crimping, the cost of which is very significant.

- Each element can be used only once.

Works are carried out as follows:

- The pipe is cut into pieces of the required diameter; both internal and external chamfer are removed from the ends.

- The sleeve is removed from the fitting and checked for integrity.

- Next, the pipe is inserted all the way, its position is easy to check on the control holes.

- Using a special tool, the assembly is clamped to the stop.

Push fittings

This option appeared relatively recently, but has already gained great popularity among buyers for a number of reasons:

- Due to the fact that you do not need to use a special tool, all the work can be done independently, while the installation speed is very high.

- The workflow is very simple, because the system is very carefully thought out.

- Each element can be removed and reused if necessary.

The only significant drawback is the relatively high cost.

Note! After installation, the connections must be held for at least 3 hours for the sealing rings to take the form of a pipe.

Works are carried out as follows:

- At first, the pipes are cut, with special attention should be paid to the slice - any scoring can damage the sealing ring.

- The pipe is inserted all the way, its correct position can be checked through a special viewing window.

- With the help of a clamping nut, the connection is fixed, with just enough half, and sometimes even a quarter of a turn.

Conclusion

Whichever option you choose, it is important to comply with the technology of the work, as the reliability and durability of the connections directly depends on it. The video in this article will help to understand some of the features of the process even better (see also the article Fittings for plastic pipes: types, device, typical problems).