Fitting for polypropylene pipes: types and their technical

Pipes made of polypropylene are very widespread in the equipment of water pipes, sewers and even heating systems. Their installation is impossible to imagine without special fittings - fittings. It is about them and will be discussed in this article.

General provisions

Why are polypropylene fittings the best way to connect plastic pipes? To answer this question, let's make a comparative description with alternative options, while taking into account that we are talking about a fusible and ductile material:

Possible types of connections

| View | Special features |

| Cut thread | Cannot guarantee sufficient bond strength |

| Threaded ferrule | It provokes deformation of the pipe, which subsequently leads to the appearance of a leak |

| Rubber seal | Creates satisfactory tightness, but loses integrity at any careless movement |

| Polypropylene fitting | By soldering creates a solid and solid connection |

As can be seen from the table, brazing is the most efficient method for connecting plastic pipes.

Merits

Now let's look at the general technical characteristics of fittings for polypropylene pipes:

- Enough high strength for mechanical damage. Typically, the thickness of the walls of the couplings exceeds a similar parameter at the pipes themselves, so the joints can be considered even more reliable.

- Versatility. It is applied in all types of pipelines.

- Complete inertness to chemicals and acceptable limit of safe heating. The ability to transport aggressive chemicals with temperatures up to ninety-five degrees Celsius.

Tip: if there are excessively cold winters in your area, it is not recommended to use polypropylene products in heating systems. Boiler rooms in abnormally severe frosts can supply water, the heating of which will exceed the permissible rate for this material, which will lead to an accident.

- Ecological purity. Respond to all existing sanitary standards.

- No tendency to corrosive processes, which is simply necessary for continuous work with liquids.

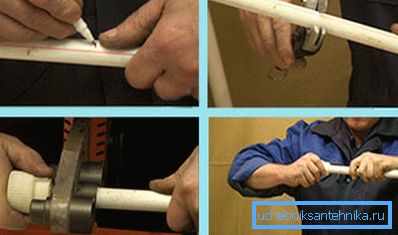

- Simple installation instructions.

- Absolute tightness after installation.

- Low price. Achieved through cheap manufacturing process.

- Durability. The operational period according to the results of various tests ranges from thirty to fifty years.

- A light weight. Does not require reinforcement of the pipeline fixtures

- Smooth inner surface. The absence of roughness significantly reduces the possibility of jams.

- A wide range of shapes and sizes, which makes it easy to choose the most suitable model.

Species

The most common sizes of fittings for polypropylene pipes are 20, 25, 32 and 40 mm.

Tip: when installing home plumbing you can safely choose twenty-millimeter products. This section is quite enough to ensure any domestic needs.

But the differences are not limited to diameters alone:

Forms

| Type of | Description | Picture |

| Clutch | A peculiar barrel for connecting two pipes, in which the inner diameter is equal to the thickness of the products inserted into it |  |

| Adapter | This coupling, in which each side has a different internal cross-section, which allows you to connect pipes with different outer diameters |  |

| Corner | It is a knee bent at an angle of 90 or 45 degrees, as well as an adapter, may in addition have different diameters |  |

| Tee or cross | Allows you to combine three or more, depending on the model, pipes |  |

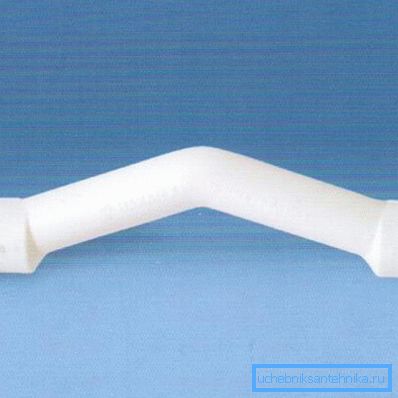

| Bypass | Curved length for pipeline passing small obstacles |  |

American

American fittings for polypropylene pipes deserve special attention. These products are used to connect plastic and steel pipes or plumbing fixtures. For this, one of their sides is provided with metal threaded elements.

May have the following types:

- Female thread coupling.

- coupling with external thread.

Conclusion

We considered what are the ways of connecting plastic pipes and came to the conclusion that the best of them is soldering, which in turn can not do without fittings. The above are the advantages and types of possible couplings. You can easily pick up the necessary parts for any, even the most complex pipeline.

The video in this article will introduce you to additional information that is directly related to the materials presented.