Fittings for metal-plastic pipes: types, device, typical

How do metal-polymer pipes connect to the water supply? How are compression or press-fittings for metal-plastic pipes arranged? Do these devices have any problems that the buyer should be aware of?

Let's figure it out.

Classification

What types of fittings for metal pipes can be distinguished?

Let's reformulate the question: by what signs can they be classified?

- Functionality. The shape and appearance of the fitting is most determined by what it is intended for: it is clear that the crosspiece, tee, corner for the mixer and the adapter from one diameter to another will look different.

- Material. Actually, the list is small: these products are mostly brass (sometimes with chrome plating); Newly introduced push-fittings are available with both brass and polypropylene housings.

By the way: under the plastic, in this case there is a brass spacer and a lock spring made of stainless steel.

- Tap diameter. Here are typical sizes of fittings for plastic pipes for different applications.

| Pipeline function | Diameter of the connected pipe |

| Liner chvs, hot water supply for one sanitary device | 16 mm |

| Liner chvs, hot water supply for several plumbing fixtures, heating pipes for one heating device | 20 mm |

| Internal wiring and risers heating, wiring heating in the cottage with forced circulation of coolant | 26 mm |

| Pouring heating in gravity system | 32 - 40 mm |

Please note: in addition to the bends for the metal-polymer pipe, the fitting may have one or several pipe threads - external and internal.

- The method of fixing the pipe. If other technical characteristics of fittings for plastic pipes do not need special comments, then it is worthwhile to dwell on this.

Pipe fixation methods

So what options are possible?

With split ring

These devices first appeared on the Russian market and to a large extent formed the attitude of the consumer to the material as a whole.

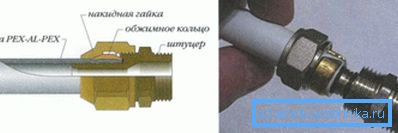

How does a split ring compression fitting work?

- The pipe is tightened on the fitting, fitted with a pair of annular gaskets, and rests against the fluoroplastic washer.

- When tightening the cap nut, it compresses the split ring, which compresses the pipe at the nozzle and prevents its accidental disconnection.

Important: sealing the connection is not provided by crimping, namely the annular gaskets. Split ring only securely fixes the pipe.

How is such a connection mounted?

Here is a typical instruction from most manufacturers:

- The pipe is cut in place with a cutter.

- Then with the help of a calibrator she gets rid of the slightest ovality. In addition, at least on the inner surface is chamfer.

- A cap nut and a split ring are successively driven onto the pipe.

- The pipe is put on the fitting to the stop.

- The split ring and nut are shifted back to the edge - also against the stop - after which the thread is tightened first manually and then with a pair of keys.

Press fitting

The pre-fittings for metal-plastic pipes are arranged somewhat differently: instead of a nut and a split ring, the pipe at the choke squeezes a clamp that is deformed by special tongs from all sides.

If in the previous case the installation of fittings for metal-plastic pipes only requires that you have a pair of adjustable or open-ended wrenches, then here you will have to get special tongs. The price of a quality tool is at least 9-10 thousand rubles; Sturdy electric mites can do in all 40.

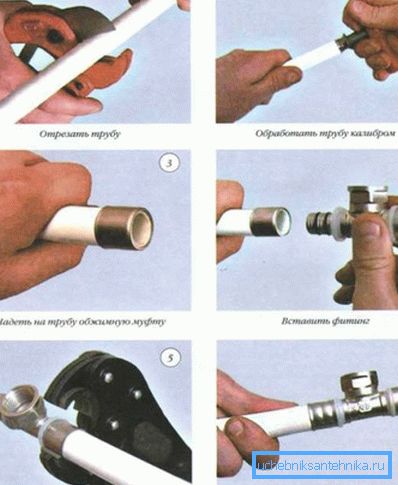

The sequence of operations differs little from that described above:

- The pipe is cut and calibrated.

- The clamp is driven from its edge.

- The end of the pipe is tightened on the fitting.

- The clamp is returned to the edge until it stops and crimped with pliers until a visible ring deformation appears.

Push

Push, or push-fittings appeared on the domestic market quite recently. Their device is very witty and does not differ in complexity.

Its main advantage is that the installation of the connection, according to the assurances of manufacturers and sellers, can be done by hand with no tools at all. It is enough to insert the end of the pipe into the annular groove, press - and the work is completed.

In this connection remains collapsible - just enough to unscrew the nut.

Nuance: a knife for cutting and calibrator still need. Ovality of the pipe and the lack of chamfers can lead to a breach of tightness under pressure.

How it works? In general, the mechanism is not difficult to understand after examining a snapshot: tightness is ensured by the same annular rubber gaskets; steel spring ring protrusions fixes the surface of the pipe, preventing its reversal. The additional liner does not allow the locking spring to move too close to the edge.

Problems

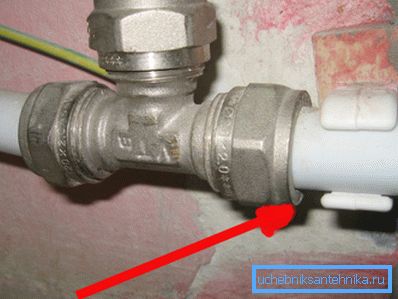

Unfortunately, thanks to the split-ring design, metal-plastic as a whole has gained a reputation for extremely unreliable material. What is the reason? Due to the fact that during the installation of hot water supply or heating a number of heating and cooling cycles began to flow.

Interestingly, the press fittings of this problem are practically devoid. There is still not enough data on push-fit fittings, so it’s too early to draw any conclusions.

So what's the problem? Why do connections flow?

And because the violations of the ovality of the pipe and unworn chamfers during assembly tear off the annular seals. As a result, after crimping with a split ring, tightness is ensured only by the inner layer of polyethylene, which is simply deformed during heating and constant pressure. When it cools down, gaps appear in which the water rushes.

Notice - not all connections flow. Only those where the rubber seal is broken.

Why press fitting this attack bypassed?

There are two reasons.

- Their fitting is arranged a little differently. Grooves with rings are deeper and harder to dislodge.

- After spending an impressive amount of crimping pliers, the installer is unlikely to save on the calibrator. At the same time, when installing compression joints, the knife is often replaced with a hacksaw, and the chamfers are not removed in principle.

So what to do if hot water flows from under the cap nut?

- Unscrew the nut and disassemble the connection.

- Re-trim and calibrate the pipe end.

- Correct or replace the O-rings.

- Reassemble.

Conclusion

We hope that our excursion into the device of some types of sanitary equipment will be useful to the reader. It is better for you to decide which fittings for metal-plastic pipes (read also the article Fitting for PVC pipes: an economical option for mounting communications).

As usual, in the attached video in this article you can find additional thematic information. Successes!