Flushing water pipelines and eliminating blockages: goals

What is the purpose of flushing water supply systems and how? Is there any instruction for its implementation? Is it possible to somehow clean the plumbing, if its patency after several years of operation has drastically decreased? Let's figure it out.

Goals

Let's immediately separate flies from cutlets, so to speak.

- Testing and flushing the yard water supply network are performed as part of the transfer of the object from the construction to the balance of the operating organization. The pipeline is tested by pressure, checked for leaks, cleaned of debris, foreign objects and disinfected.

Important: cold water is positioned as drinking, which implies strict requirements for the composition of the water.

- If the capacity of the water supply is significantly below the norm for a pipe of a given diameter, it needs mechanical cleaning or chemical washing with reagents that dissolve limescale and rust. The use of hydropneumatic flushing in this case, as a rule, does not bring any result.

Testing, washing, disinfection: regulatory requirements

Tests

The order of hydraulic tests is exhaustively set forth in SNiP 3.05.04-85, which regulates, in particular, the construction of external water supply networks.

According to SNiP, the test should be carried out hydraulically or, if it is impossible to fill the pipeline before it is put into operation, by air. The pressure during testing should be:

| Type of pipeline | Test pressure |

| Welded steel, pressure up to 7.5 kgf / cm2 | Working x Ratio 2 |

| Welded steel pressure from 7.5 to 25 kgf / cm2 | Working x Ratio 1.5 |

| Cast iron with sockets for chasing | Working + 5 kgf / cm2, but not less than 10 and not more than 15 |

| Cast iron with sockets on rubber seals | Working x ratio 1.5, but not less than 15 kgf / cm2 |

| Reinforced concrete | Working with a coefficient of 1.3 |

| Asbestos cement | Also |

| Plastic | Also |

Disinfection and Rinsing

Guidelines for disinfection of water supply can be found in the same SNiP.

According to the document, for it you can use:

- Bleach solution.

- Sodium hypochlorite solution.

- Liquid chlorine.

Flushing (cleaning) of the pipeline can be performed:

- Elastic piston. As a rule, this role is played by a foam rubber cylinder with a diameter of 1.3 times the internal diameter of the water supply system and a length of 1.5 - 2 diameters.

- Water, distilled through a section of water for discharge.

- Pulp (water-air mixture). Hydropneumatic flushing is organized by air supply by the compressor; The optimal ratio of water and air in the pulp is 1: 1.

SNiP contains several additional recommendations for professionals performing washing and disinfection.

Foam piston can be used in areas with smooth turns at an angle of no more than 15 degrees with valves fully open and in the absence of protruding structures. The speed of the piston at a pressure in the pipeline of 1 kgf / cm2 should lie in the range of 0.3 - 1 m / s. In this case, the diameter of the discharge, through which contaminants leave the water supply system, can only be a step smaller than the diameter of the flushing pipe.

When hydropneumatic flushing air should be fed into the pipeline under a pressure of 0.5-1.5 atmospheres exceeding the pressure of water. The speed of the pulp should lie within 2 - 3 m / s.

Disinfection of pipelines is carried out in areas no longer than 1-2 km at a time. At the same time after every 500 meters temporary control valves are installed for sampling for chlorine concentration.

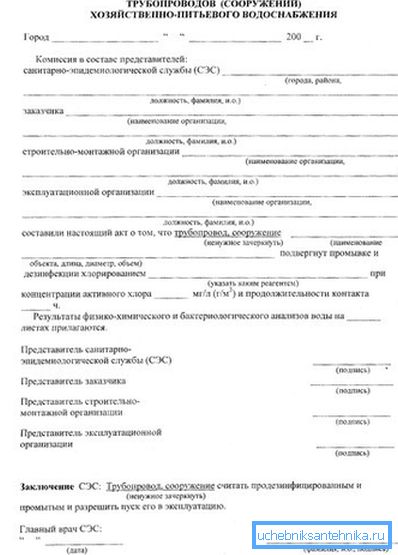

As a result of the work, an act of washing the internal water supply systems and disinfecting them is drawn up.

Its text should indicate:

- The composition of the commission (SES, construction and installation organization and operators).

- Description of the object (type, length, diameter, volume).

- Type of reagent and concentration of active chlorine.

- Duration of treatment.

- The results of biological and physico-chemical analyzes of water after treatment.

Elimination of blockages

Fighting pipe blockages in a cold water system is very different from flushing the heating system or cleaning the sewage system. The key difference is that the blockage cannot be destroyed by the flow of water or by a weak mechanical effect: the pipes are overgrown with strong limescale deposits and rust.

By the way: sometimes sand or a piece of scale becomes the initial cause of a blockage. If it is not removed immediately, after a while the blockage cements and is susceptible to destruction with great difficulty.

Is it possible to do something with your own hands, if in a house with an old steel water supply the pressure of the water has catastrophically dropped?

- Try plugging the mixer gander with your finger while simultaneously opening the hot and cold water taps. The dhw pressure is noticeably higher most of the year; the backflow can destroy the fresh blockage, after which its fragments will be carried to the sewage by water.

- If this does not help - repeat the operation, dropping the cold-water strut. The pressure drop between the DHW and the empty riser will be much greater.

- Is the water still not running at normal pressure? Open the valve (of course, when the riser is dropped). Debris deposits under the valve seat are a typical problem of cast iron and, to a lesser extent, brass screw valves.

- Finally, if all else fails, try to disassemble all available threaded connections and clean the pipe with a steel string from the curtain rod, bending a pin-sized hook at its end. On the second side of the string, a knob is formed, resembling the well gates. The string is fed into the tube with continuous rotation; after it passes the site of the blockage, its remains are washed with water.

Tip: calcareous deposits dissolve well with acid solutions. It is enough to plug the pipe near the valve and fill it with a reagent for a couple of hours. As the active substance, you can use imported Cillit or, which is much better, a solution of dry oxalic acid: its price is several times lower at much higher chemical activity.

Conclusion

We hope that we managed to satisfy the reader’s curiosity, and at the same time help him in solving some everyday problems. Additional useful information will be offered to his attention by the video in this article. Successes!