Galvanized profile pipe 20x20: we study the types and

Metal in today's world is used in various areas of human life. In our time, it is the profile tubes that have become widespread. Such popularity is due to the winning design of products, which saves the metal used for the manufacture of various structures, due to the presence of stiffeners.

Of all the varieties of materials of rectangular cross section, galvanized pipe 20 20 or other sizes are especially in demand, due to the fact that zinc coating allows to protect the structure from corrosion, and extends the service life in comparison with simple ferrous metal pipes.

What is a profile tube

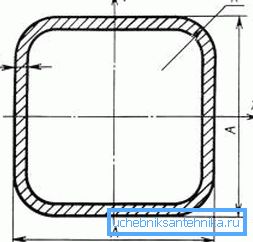

As soon as people hear the word trumpet, associations with products of circular section come to mind. However, the profile products are both round, and oval, and rectangular, and even a square tube 20 20 or other sizes.

The basis for the production of such materials is steel. The plasticity of this raw material allows you to produce finished products endowed with additional qualities.

In practice, products made by such methods are often found:

- Hot-formed;

- Seamless;

- Cold formed;

- Electrowelded, cold formed.

According to the regulatory documentation, the profile metal can be made of such types of steel as:

- ST2kp;

- ST2sp;

- ST2ps;

- ST4kp;

- ST4ps;

- ST10ps;

- ST4sp;

- ST08kp, etc.

Zinc coating

The technology of deposition of zinc coating is of two types:

- Complete immersion of finished products in electroplating baths with a zinc solution in a hot condition. In this case, the zinc layer is formed both from the inside and from the outside.

Note! The thickness of the zinc layer on the surface of the parts directly depends on how many times the pipe 20 20 2 has been immersed in the electroplating bath.

- The manufacture of the finished product from steel sheet, already possessing a zinc coating. In this embodiment, the method of hot-dip galvanizing by dipping into a galvanic bath not only finished products, but steel sheet.

Note! This method is considered advanced, but it has one serious drawback. The fact is that in the process of manufacturing the welded method in the place of the weld, a layer of zinc simply burns in the flame of welding. In the event that the seam after all the processes is not treated with zinc, the pipe 20 20 1 5 will be subject to corrosion processes.

For any metal, the main enemy reducing its operational period is corrosion or rust. The process of steel rusting occurs under the influence of air and water. It is the zinc layer that prevents the access of these two elements to the metal, prolonging the service life of the metal-roll.

Note! The hot zinc coating method provides reliable metal rust protection. Compared to plain black steel, galvanized pipes last 5-6 times longer.

Types of specialized products

The profile of galvanized type, depending on the method of manufacture, is produced:

- Dimensional length:

- Cold rolled 4,5-9 m;

- Electrowelded 5-9 m;

- Hot rolled 4-12.5 m;

- Not measured length:

- Hot-rolled seamless 4-12.5 m;

- Cold-formed seamless 1.5-9 m;

- Welded 1.5-9 m;

- Multiple measured length with allowances:

- Hot-rolled seamless 4-12.5 m, allowance - 5 mm;

- Cold-formed seamless 1.5-9 m allowance - 5 mm.

In addition to the shape and cross section, the differences may depend on the wall thickness, because the products are thin-walled and thick-walled.

Advantages of galvanized structures

The advantages of materials with zinc coating include the following:

- Efficiency of the installation of structures. With equal bearing capacity, for example, a profile pipe and a corner of steel, the consumption of the metal itself for the production of such products will be markedly reduced. The weight of the pipe 20 20 2 will be much less than the weight of the angle;

- Compactness of finished products, which allows you to easily store, assemble, disassemble, store and transport profile metal;

- Simple and easy installation, in comparison with round pipes or other types of metal products, which allows to significantly reduce the time spent on construction. And these factors indirectly affect the cost of the construction process;

- Four stiffening ribs guarantee the strength of the profile products, which guarantees resistance to various kinds of deformations;

- Low price and low complexity.

The construction of structures in which the fittings are replaced with galvanized metal profiles, leads to cheaper construction process, extending its service life, and reducing the weight of the structure due to the fact that the weight of 1 meter of pipe 20x20x2 will be several times less.

Scope of the profile metal

Profile steel materials have found application in many branches of human life:

- Building;

- Life;

- Aviation;

- Shipbuilding;

- Industry;

- Private house building;

- Furniture manufacturing, etc.

Different types of frames for residential buildings, industrial buildings, car filling stations, hangars and warehouses are constructed from the profile metal with a section in the form of a square or rectangle.

Of this type of products arrange canopies over car parks, swimming pools, terraces and gazebos. Gardeners have long chosen the profile pipes for the construction of greenhouses, greenhouses, fences and garages.

Products of small section have long been used in the manufacture of furniture for medical institutions, bus stations, offices, railway stations and airports. Street advertising counters, signs on motorways, public transport stops, etc., the list is endless because similar materials are used everywhere.

Note! In any areas where an increased level of safety of structures is required, galvanized profile thick-walled pipes are used, made by a seamless method, which meet the requirements of reliability and strength due to the absence of seams at the maximum level.

Thin-walled metal has found application in the creation of light civil structures, where the load level is minimal and insignificant, stopping, pavilions, garden furniture, canopies and gazebos for rest can be an example of this type of structure.

Such demand for such galvanized metal pipes is due to the fact that they have high technical parameters:

- Long service life;

- Low pipe weight 20x20x2;

- Resistance to rusting.

Finally

Despite the fact that galvanized profile pipes are used in the same areas of human activity as ordinary black steel, due to the presence of anti-corrosion coating, they serve many times longer, and this is due to their popularity in the modern market.

And the video in this article will tell you even more about the positive qualities of galvanized rolled metal.