Galvanized profile pipe: production, characteristics and

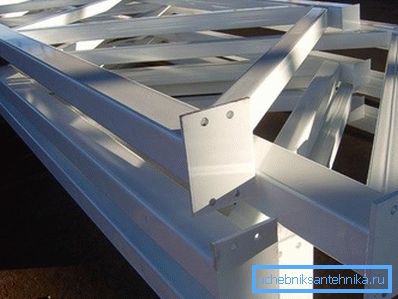

In this article, we will look at what the instructions for the use of core pipes, as well as tell you about the characteristics and characteristics of the production of these hardware. The topic of the article is not accidental, since pipes with a non-circular cross-sectional shape are widely used in both industrial and handicraft production of a wide range of various metal structures.

The range of rolled products is wide, but the most interesting are those positions that are characterized by maximum resistance to the negative impact of environmental factors. Therefore, in this article we will focus on the most durable galvanized pipe modifications.

Main characteristics

The profile galvanized pipe 20х20, as well as analogs with other standard sizes, possess a number of distinctive advantages, in comparison with not galvanized hire, among which:

- Economical consumption in the construction of various metal structures. With the same bearing capacity, the production of galvanized shaped pipes takes less metal than similar products from ordinary low carbon steel.

- Lighter weight compared to products from conventional low carbon steel.

- Convenience of storage, storage and transportation due to specific configuration.

- The simplicity and efficiency of the installation work with their own hands, compared with the use of metal with a round cross-sectional shape.

- Resistance to mechanical loads is not less than the parameters demonstrated by circular analogues.

- Resistance to corrosive processes and, as a result, the possibility of use for the construction of externally located metal structures.

- Affordable price in combination with the above qualities leads to cheaper finished metal structures.

Main varieties

Important: Galvanized sections, regardless of the method of manufacture, must comply with the requirements given in GOST 8645-68.

Profile galvanized pipes, in accordance with the method of manufacture, are subdivided into articles of measured and non-dimensional length.

Modifications of measured length are represented by the following hardware:

- hot-rolled - with a length of 4-12, 5 m;

- electrowelded - 5-9 m;

- cold-deformed - 4.5-9 m.

Modifications of unmeasured length are made with the following parameters:

- hot-rolled seamless pipes - with a length of 4-12.5 m;

- cold deformed seamless - 1.5-9 m;

- electrowelded - 1.5 to 9 m.

Profile rolled products with multiple dimensional lengths can be manufactured with allowances for connecting seams:

- cold deformed seamless - with a length of 1.5-9 m, the size of the allowance is not more than 5 mm;

- hot-rolled seamless - with a length of 4-12.5 m, the size of the allowance is not more than 5 mm;

- Electric products are manufactured with different multiplicity of lengths.

In addition to the cross-sectional shape and length, the classification of such rolled products takes into account the wall thickness. In accordance with these parameters, the profile products on the market can be thin-walled or thick-walled.

Production features

Production of specialized galvanized pipes is carried out using carbonaceous alloyed steel grades St2sp, St2ps, St4sp, St4ps, St4kp, 0.8kp, 09Г2С, 10ps, etc. Steel production for the subsequent manufacture of rolled products is carried out in accordance with the requirements of GOST 8639-82.

Pipe production is carried out by cold or hot forming. For these purposes, an electric-welded straight-seam pipe with a conventional circular cross section, which is given the required shape, is manufactured from sheet steel. Forming blanks by using special rolls.

At the end of the production cycle, finished metal, in accordance with the requirements of state standards, undergoes non-destructive testing of the quality and strength of the weld. The final stage is heat treatment, during which internal mechanical stresses are removed.

The application of a protective layer of zinc is carried out in conditions of elevated temperature and the complete absence of oxygen. Only due to the absence of oxygen during galvanizing, it is possible to ensure the subsequent reliability and durability of the finished metal.

Important: The manufacturing process, during which a 20x20 or 40x20 galvanized pipe is manufactured, must comply with the requirements of GOST 13663-86, while a profile with a square cross-sectional shape is manufactured in accordance with the requirements of GOST 8639-62.

The range of rolled products produced by domestic manufacturers with standard sizes of 10? 10 mm - 500400 mm, with a wall thickness of from 1 to 22 mm and a length of from 6 to 18 meters.

Scope of application

Profile pipes, made of steel and protected by a layer of zinc, are used in various industrial and commercial areas, among which are the following:

- construction of residential, public and industrial buildings;

- production of most modern greenhouses covered with hard or soft covering materials;

- production of various furniture;

- aircraft construction;

- automotive industry;

- shipbuilding.

Of course, the list of areas in which shaped pipes can be applied is much wider and this popularity is largely due to the technical and operational characteristics of this metal-roll.

Let us consider in more detail how to apply the profile hire with regard to its operational advantages.

Corrosion-resistant metal products used in the manufacture of frames for the construction of various buildings. This application is due to the fact that corrosion-resistant metal products with high rigidity and strength indicators will withstand substantial mechanical loads for a long time without the need for regular maintenance and repair.

Approximately for the same reason, galvanized metal is used to assemble a variety of metal structures for subsequent operation in the open air. After all, factory corrosion-resistant coating eliminates the need for the use of paints and varnishes.

Therefore, supports for fences, sheds, stops for public transport, gazebos, covered with polycarbonate, etc. are made of such pipes.

A separate moment associated with the use of steel corrosion-resistant metal, this is the construction of greenhouses from shaped pipes. Greenhouses with the use of such hardware are built on both industrial and artisanal scales.

There are several good reasons for using such a manufacturing material. As already mentioned, the rectangular profile provides the metal structures with optimum rigidity, which is important when building relatively light structures that resist the mechanical load of wind gusts.

Moreover, condensate may form at the point of joining the metal with polycarbonate or film. And only galvanized metal for a long time can be used for its intended purpose without the appearance of rust.

Conclusion

So, we reviewed the main areas of application and features of the production of galvanized shaped pipes. In addition, we talked about the technical and operational characteristics of these products. Now you know what materials to use when assembling a greenhouse or frame for the construction of a building object.

Have any questions? More useful information you can find by watching the video in this article.