Garden pipe made of polyethylene pipes - what is the

Private suburban residence, in common called dacha, can not exist without running water, it is an axiom. Overwhelmingly, our hardworking people prefer, if possible, to equip everything with their own hands. Plastic water supply in the country is suitable for this purpose as well as possible. The main competitor of this option is the dacha water from polypropylene. The following discussion will focus on where and how best to use these materials.

Comparative analysis

We did not accidentally choose these two types of polymer pipes. The fact is that steel is heavy and that even more unpleasant, quickly rusting. Metal pipes are of high quality, but they are expensive, plus they are not always suitable for gardening.

All sorts of soft hoses are good, but more focused on partial use.

Therefore, we return to our polymers.

- Polyethylene is a completely environmentally neutral material.. It does not interact with chemically aggressive fluids, therefore it is harmless to the environment. Polypropylene, in this case in no way inferior, it is also environmentally neutral.

- Polypropylene is considered more resistant to pressure drops.. But in summer houses there is often no high pressure. As a maximum, when using powerful pumping systems, there is the likelihood of a short-term water hammer, which both materials can easily cope with. It turns out that in this indicator, these polymers are also equal.

- Polypropylene pipes for water supply in the country can withstand temperatures of more than 100? С. Extruded polyethylene holds a maximum of +60? С; ordinary HDPE pipes +40? С. It is not so important for the watering system, but it turns out that it is better to use polypropylene for the water supply of the building.

- Polypropylene, as well as extruded polyethylene is not afraid of exposure to ultraviolet radiation, which is not the case with standard HDPE pipes. Watering plumbing pipes made of polyethylene pipes in the country are recommended by experts to be installed underground or to hide it in the grass.

- As for elasticity, then polyethylene has no equal. These pipes are sold in coils, so it is very convenient both to transport and lay them on the ground. Products from polypropylene practically do not bend, all turns are mounted using fittings.

Important: in addition to the indicators of linear elasticity, there are still characteristics of stretching. Both polymers have approximately the same data in this niche. If water pipes freeze in the pipes, they will only stretch slightly, but will not burst and do not deteriorate.

- Polyethylene pipes for water supply in the country, compared with competitors, it is much easier to mount. In addition to the pipe cutter and possibly pliers with a screwdriver, you will not need any tools. Everything is twisted with its own hands crimp fittings. For installation of polypropylene plumbing you will need a special soldering iron.

Tip: during operation, the crimp fittings require periodic tightening, otherwise they begin to leak. Therefore, for underground installation, detachable fitting connections should be left open. Soldering in this respect is much more durable.

- Finally we got to one of the most important issues, this is the price. It is traditionally considered that summer plastic water supply in the country will cost less than polypropylene structures. The pipes themselves are certainly cheaper, but the price of compression fittings can equalize the costs. Here we must assume that the more connections, tees and cranes, the higher the cost.

Principles of installation of water supply

From all of the above, we can conclude that the dacha water supply system made of polypropylene is more focused on installation inside the building or laying, if possible, direct underground lines. Polyethylene is better suited for summer watering options. The good news is that the assembly instruction, in both cases, is quite accessible for a simple inhabitant to master.

Polyethylene wiring

As mentioned earlier, PND pipes bend well enough, so they are ideally suited for the installation of summer watering pipe. Such a system can be assembled or disassembled within a few hours.

Often in the dacha farm used pipes with a cross section of 20 to 40 mm. It all depends on the size of the site. For a small cottage in 6 - 8 hectares enough 25 mm. If your garden or irrigation lawn extends over a larger area, then a complex system is needed, where pipes with a cross section of 35–40 mm are installed on linear highways, and wiring along the beds is done with pipes 20–25 mm.

Initially, you need to draw on paper a diagram of the pipeline, you will need it to purchase the material. Moreover, it is better to make it directly on the ground, to go through the entire route and mark where you will be, it is convenient to draw conclusions or turns.

Although the pipes can easily withstand the hitting of garden equipment, but still they are better to prikopat or, at least, to make a small groove, so as not to stumble over them. Stationary wiring under the tracks buried to a depth of 15 - 20 cm. If you decide to lay a highway directly under the beds, then you need to bury it at least 30 cm in order not to damage the bayonet.

Crimp or compression fittings are put on the pipe and tightened with bare hands, if the hand strength is not enough, then take the wrench. Just remember that it is still plastic and tighten without fanaticism.

Polypropylene wiring

It is not difficult to assemble plumbing from polypropylene with your own hands at the cottage, but for this you will definitely need a special soldering iron. All couplings, tees or adapters are mounted exclusively by soldering. By the way, the price of all these accessories is much lower than that of compression fittings for polyethylene pipes.

Tip: You can certainly buy a soldering iron, it costs from 2,000 rubles, but for one-time work it is better to rent it. In some building supermarkets, when purchasing a large quantity of goods, the service of renting a soldering iron can be a bonus.

Suburban water pipe made of polypropylene is laid on the same principles as the polyethylene system, only with turns of 90 ?. Therefore, we are interested only in the soldering instruction.

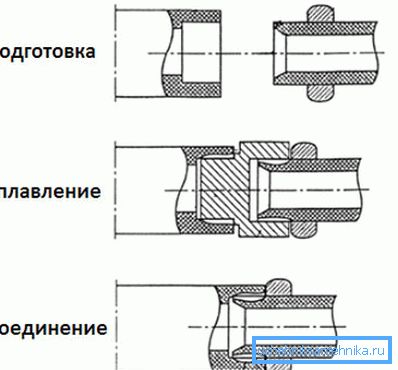

When the soldering iron is heated, as indicated by the sensor, the pipe and fitting are inserted into special sleeves on both sides. The material will melt within 20-30 seconds.

After that, you need to quickly remove from the soldering iron, connect and fix the details. It is necessary to keep motionless up to 60 seconds, until the plastic hardens. After half an hour you can let the water.

The video in this article has additional material on the topic.

Conclusion

In conclusion, it is worth adding. Laying stationary pipe wiring in the country, and it does not matter in the house or in the garden, always done at a slight inclination. This will give the opportunity to drain the water from the system while preparing it for the winter.